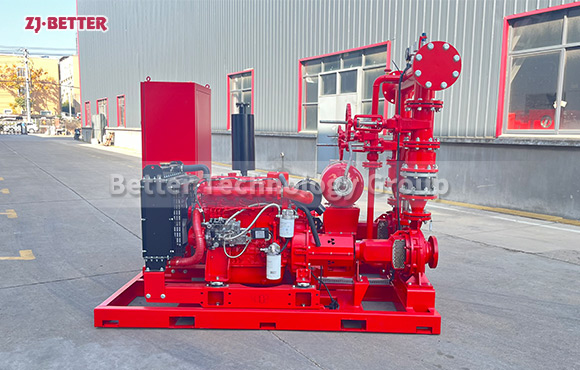

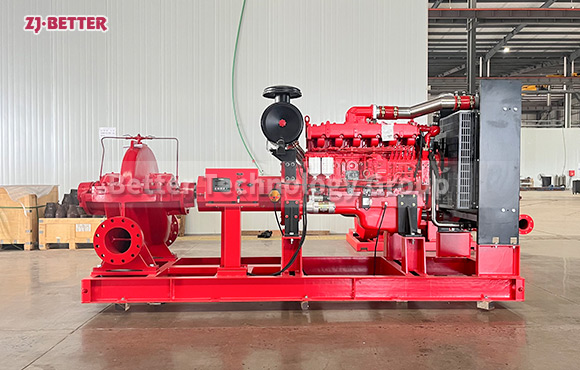

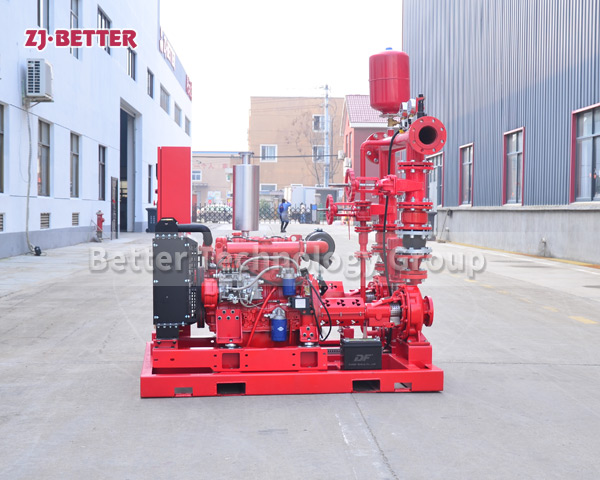

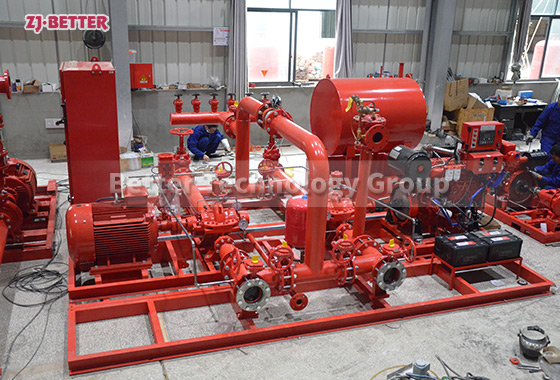

High Head and Large Flow Diesel Fire Pump Unit for Large Building Fire Protection

High-lift, high-flow diesel fire pump units are powered independently by diesel and do not rely on mains power. They start quickly, operate stably, and are suitable for fire water supply systems in large buildings, industrial parks, and warehousing centers. They feature efficient water delivery, intelligent control, and reliable safety performance.

This product is a high-lift, high-flow diesel fire pump unit, specifically designed for large buildings, industrial parks, commercial complexes, warehousing and logistics centers, and other locations with extremely high requirements for fire water supply. It provides continuous, stable, and powerful fire water supply in emergencies such as fires. The unit utilizes an independent diesel power system, operating without external power sources. It can quickly start and operate stably under conditions of power outages, power system failures, or complex operating conditions, ensuring the fire protection system remains functional at critical moments. The entire unit uses a high-performance diesel engine as its core power source, featuring rapid start-up response, stable output power, and strong load adaptability. It can quickly deliver water to high-rise buildings or the end of long-distance fire pipeline networks, meeting the stringent requirements of large building fire protection systems for both high lift and high flow rate. The fire pump section employs a high-efficiency hydraulic model design. Through precise calculations of the impeller structure and flow channel layout, it effectively reduces hydraulic losses and improves overall operating efficiency, maintaining stable head performance while ensuring high flow output. It is particularly suitable for complex fire water supply scenarios such as super high-rise buildings, underground spaces, and cross-regional pipeline networks. The pump body is made of high-strength, wear-resistant material, possessing excellent corrosion resistance and pressure resistance. It can operate under high load and high-frequency start-stop conditions for extended periods, significantly extending equipment lifespan and reducing maintenance costs. The shaft sealing system employs a reliable mechanical seal structure with excellent sealing performance, effectively preventing media leakage and ensuring safe and stable operation of the fire pump under high pressure. The diesel engine and fire pump are connected via a high-precision coupling, resulting in high transmission efficiency, low vibration, effectively reducing mechanical wear, and improving overall operational stability. The unit’s overall structure features an integrated base design, with the engine, fire pump, control system, and auxiliary components scientifically arranged, resulting in a compact structure, small footprint, and easy on-site installation and system integration. This makes it particularly suitable for projects with limited space but extremely high fire safety requirements. In terms of control performance, this diesel fire pump unit is equipped with a complete automatic control system, supporting multiple control modes such as automatic start, manual start, and remote signal start. It can seamlessly integrate with the building’s fire alarm system. Once a fire signal or abnormal pipeline pressure is detected, the system can automatically start the diesel engine and drive the fire pump to work in a very short time, greatly shortening the fire response time. The control system features multiple operational status monitoring and protection functions, capable of real-time monitoring of engine speed, oil pressure, water temperature, battery voltage, and pump unit operating status. In case of abnormalities, it promptly issues alarms and implements protective measures to prevent equipment damage and ensure long-term reliable system operation. Addressing the continuous water supply requirements of large building fire protection systems, the unit’s cooling system employs a highly efficient water-cooling or air-cooling solution, maintaining stable engine operation under high ambient temperatures and prolonged operation, preventing overheating and performance degradation. The fuel system is optimized for stable fuel supply and high combustion efficiency, effectively reducing fuel consumption and improving economy while ensuring output power. The diesel fire pump unit’s performance parameters are designed to fully consider the differentiated needs of various projects, offering a wide range of head and flow rates. It can be rationally configured according to actual working conditions, flexibly adapting to fire protection systems of different heights, pipe diameters, and water supply distances, providing greater flexibility in engineering design. The product is manufactured in strict accordance with relevant fire protection and industrial equipment standards. From raw material selection and processing technology to complete assembly, it undergoes multiple quality controls and performance tests to ensure that every unit meets high standards in terms of startup performance, operational stability, and safety reliability. Before leaving the factory, the entire unit typically undergoes simulated operating condition testing to verify its actual operating capabilities under high head and high flow conditions, ensuring reliable performance in real fire environments. This diesel fire pump unit is suitable not only for newly constructed large-scale building projects but also for upgrading existing building fire protection systems, effectively improving the water supply capacity and emergency reliability of the original system. With its independent power, efficient water delivery, stable operation, and intelligent control, this product demonstrates strong applicability and competitiveness in the field of fire protection water supply for large buildings. It is one of the key core devices for building a high-level fire safety system, providing a solid, continuous, and reliable fire water guarantee for densely populated areas and critical infrastructure.