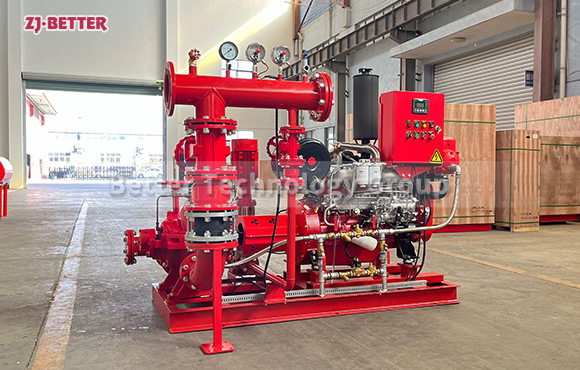

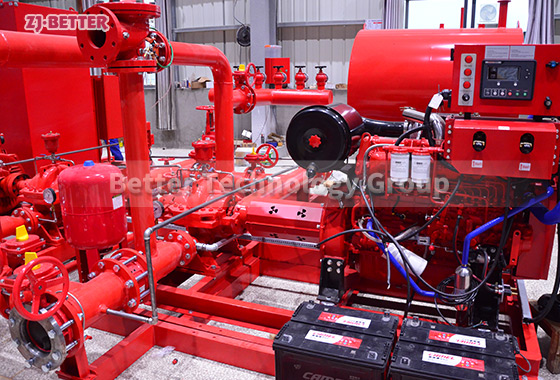

Innovative Design and Application of High Head and Large Flow Diesel Fire Pumps

High-lift, high-flow diesel engine fire pumps offer powerful power, high lift, and large flow rates. Suitable for long-distance water supply scenarios such as high-rise buildings, ports, and petrochemicals, they feature intelligent control, durable structure, and stable performance, ensuring efficient and reliable fire emergency water supply.

The high-lift, high-flow diesel fire pump is an emergency firefighting device that combines powerful power, stable performance, and efficient water delivery. It is designed for use in large buildings, industrial parks, petrochemical storage facilities, ports, and other locations requiring long-distance, high-flow water supply. Powered by a high-power diesel engine, it operates independently of utility power, ensuring continuous and stable water supply even during power outages or extreme conditions. Its high lift allows the water flow to overcome pressure losses caused by high-rise buildings or long-distance delivery, ensuring stable and sufficient water pressure at the terminal nozzles. Its high flow rate ensures a sufficient amount of water to the fire scene in a short period of time, effectively controlling the spread of the fire. The pump body is cast from high-quality, wear-resistant materials and undergoes precision machining and dynamic balancing tests to ensure efficiency and stability even under long-term, high-load operation. Optimized flow path design effectively minimizes hydraulic losses and improves overall hydraulic efficiency. The diesel engine is equipped with a high-pressure common rail fuel system, offering high combustion efficiency and rapid response. It reaches rated speed and begins operation within seconds of receiving the start signal, significantly shortening firefighting response time. The cooling system utilizes a large-capacity water-cooling or composite cooling structure, maintaining engine temperatures within a safe range even under high temperatures or prolonged continuous operation, preventing performance degradation due to overheating. The unit is equipped with an intelligent control cabinet that supports manual, automatic, and remote start modes. It can be linked to the automatic fire alarm system to enable unattended automatic pump startup. The control system includes built-in fault diagnosis and protection features, including low oil pressure alarms, high water temperature alarms, overspeed protection, and low fuel warnings. These ensure the unit automatically shuts down or reduces load in the event of an emergency, extending its service life. The sealing system of this high-lift, high-flow diesel fire pump utilizes a combination of mechanical seals and auxiliary seals, providing excellent leak-proof performance and adaptability to diverse water conditions, including clear water, slightly muddy water, and seawater. The bearings feature a heavy-duty design and an independent lubrication system, reducing wear and extending maintenance intervals. The base is a one-piece welded steel structure with high strength and earthquake resistance, and is treated with an anti-corrosion spray coating for long-term operation in harsh outdoor environments. The unit’s compact design and small footprint make it easy to install in a pump room, container pump station, or mobile trailer platform. This diesel fire pump not only meets international fire protection standards in terms of performance, but also offers customized head, flow rate, interface specifications, and control logic to meet the specific requirements of different countries and regions. In practical applications, it can deliver water up to 100 meters in high-rise buildings, rapidly supply water to distant fire sources at ports and docks, and provide high-flow emergency cooling and firefighting support in high-risk areas in the petrochemical industry. Maintenance is carefully considered in the design. Wear parts such as the fuel filter, oil filter, water pump impeller, and mechanical seal are easily replaceable. Daily inspections can be performed through an inspection window or convenient access hatch, significantly reducing maintenance effort and time. The entire unit features a vibration and noise-optimized design, resulting in low operating noise, meeting environmental requirements for both industrial and residential areas. Fuel consumption is also kept within an economical range, ensuring high-flow output while reducing operating costs. Overall, this high-lift, high-flow diesel fire pump, with its superior power performance, robust water supply capacity, exceptional durability, and intelligent control system, is an ideal choice for handling large and complex fire scenes. It provides solid support for firefighting and rescue operations at critical moments. Whether in remote areas, areas without electricity, or urban cores with extremely stringent water supply requirements, it delivers stable and reliable performance.