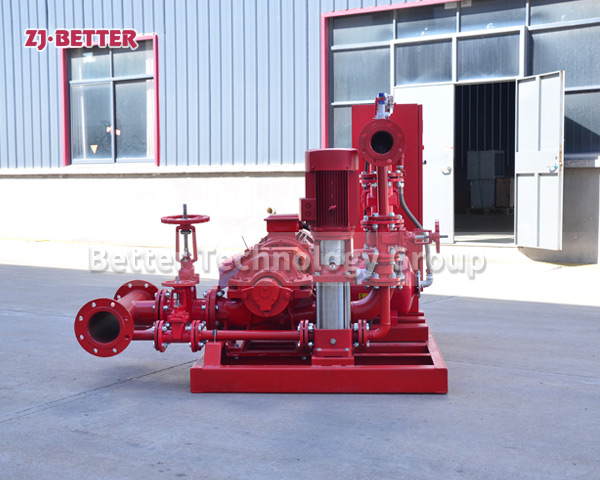

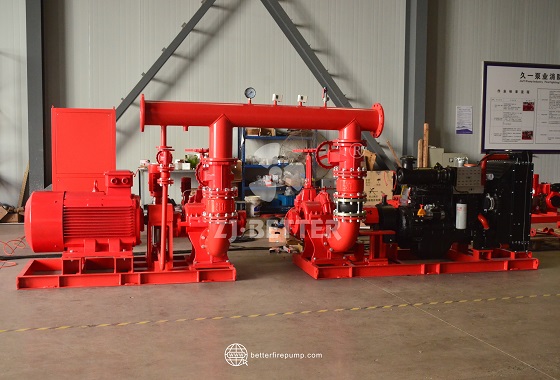

Multiple-Specification Fire Pump Motors to Meet Diverse Application Needs

Various specifications of fire pumps are equipped with motors that are suitable for various pump types and working conditions. They have the advantages of efficient power output, high temperature resistance and corrosion resistance, low noise and long life. They support multiple starting and cooling methods to ensure stable and reliable operation of the fire protection system.

Multi-specification fire pump motors are key equipment designed to power fire pumps of varying types and specifications. They play an irreplaceable role in the entire fire protection system, enabling flexible matching based on a variety of conditions, including usage scenarios, pump type requirements, flow and head parameters, and power requirements, ensuring optimal fire pump performance in a variety of environments. Whether in high-rise buildings, large industrial plants, petrochemical bases, airports, ports, or municipal water supply systems, these motors can be configured with the appropriate power level, speed, and protection level based on actual operating conditions, making fire pump operation more efficient, safe, and stable. The greatest advantage of multi-specification design lies in its adaptability. Different motor models vary in power output, torque characteristics, starting methods, and insulation levels, enabling precise matching with a variety of fire pump types, including centrifugal, vertical, horizontal, and multi-stage pumps, thereby avoiding efficiency degradation and equipment damage caused by insufficient power or overload. The motor’s casing is constructed of high-strength cast iron or high-quality steel plate, sprayed with a corrosion-resistant coating for excellent water, dust, and rust resistance. It can operate stably in environments with humidity, high temperatures, dust, and even corrosive gases. The motor’s internal windings are primarily made of high-grade insulated copper wire and undergo a vacuum pressure varnishing process to ensure the coil’s heat resistance and insulation, enabling it to withstand high loads for extended periods without degradation. High-quality ball or roller bearings, combined with an efficient lubrication system, ensure low noise and vibration, extend service life, and reduce maintenance costs. In terms of electrical performance, various fire pump motors are available in various voltage levels and frequency formats, suitable for both standard 50Hz and 60Hz power systems, facilitating global application. Select models feature a high-efficiency variable frequency speed control function. By connecting to a fire control system, the motor automatically adjusts speed and power output based on fire conditions, achieving a balance between energy-saving operation and rapid response. Starting methods include direct start, auto-coupling step-down start, soft start, or variable frequency start, depending on power consumption and on-site grid conditions. This reduces the impact of starting current on the grid and extends equipment life. To cope with unexpected fire conditions, these motors are typically designed with Class F or H insulation and IP54, IP55, or even IP56 protection levels. They can operate reliably in short-term high temperatures, strong water flow, and dense dust. Cooling options include IC411 air cooling, IC416 external fan cooling, and IC81W water cooling to meet diverse indoor and outdoor installation conditions and ambient temperature requirements. The motors for fire pumps in various specifications are manufactured in strict compliance with international and national standards, such as IEC and GB. Each product undergoes rigorous dynamic balancing, insulation withstand voltage, and no-load and load tests before shipment to ensure stable performance and reliable quality. Their design lifespan typically exceeds 10 years, and with proper maintenance, they can even last longer. This offers exceptional value for fire protection systems that require long-term, reliable operation. In terms of installation, the motor base is designed to be stable and equipped with standardized mounting holes, which facilitates quick docking with the fire pump. It also supports horizontal installation, vertical installation and other methods to adapt to different pump group layout requirements. Maintenance convenience is also a major feature of the motors for multi-specification fire pumps. Its structure is highly modular, and key components are easy to disassemble and assemble. Routine maintenance such as bearing replacement, winding inspection, and cooling system cleaning can be completed in a short time, greatly reducing downtime. The motors for multi-specification fire pumps are not just a single power source. They form a complete fire water supply guarantee chain with the fire pump, control system, and pipe network system. When a fire occurs, the rapid start-up and stable operation of the motor directly determine the water output efficiency and fire extinguishing effect of the pump. In modern smart fire protection systems, this type of motor can also be connected to the Internet of Things monitoring platform to upload operating data and status information in real time, making it easier for management personnel to remotely monitor and take timely measures when abnormalities are found, further improving the reliability and safety of the fire protection system. Overall, the motors for fire pumps in various specifications, with their wide adaptability, excellent performance, robust design, diverse starting and cooling options, and easy maintenance, can meet the fire water supply needs of various operating conditions, from civil buildings to large-scale industrial facilities. They not only ensure maximum fire pump efficiency at critical moments but also provide efficient, energy-efficient, and durable power support during daily operation. They are an indispensable component of modern firefighting systems and a key component in protecting the lives and property of personnel.

-2.jpg)