Long-Running Fire Equipment: How Diesel-Driven Water Pumps Enhance Rescue Efficiency

Discover how a high-performance diesel-driven fire pump enhances emergency response with continuous operation, fast startup, strong pressure output, and exceptional reliability in demanding firefighting environments. Perfect for industrial sites, remote areas, and critical fire protection systems.

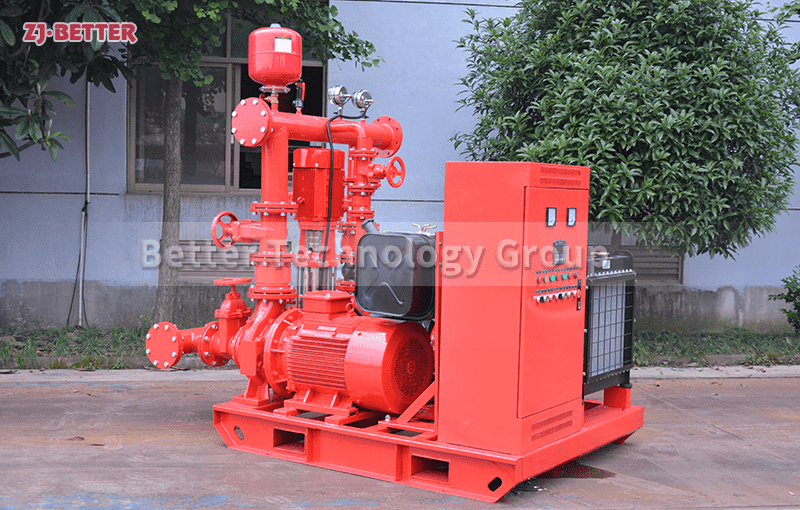

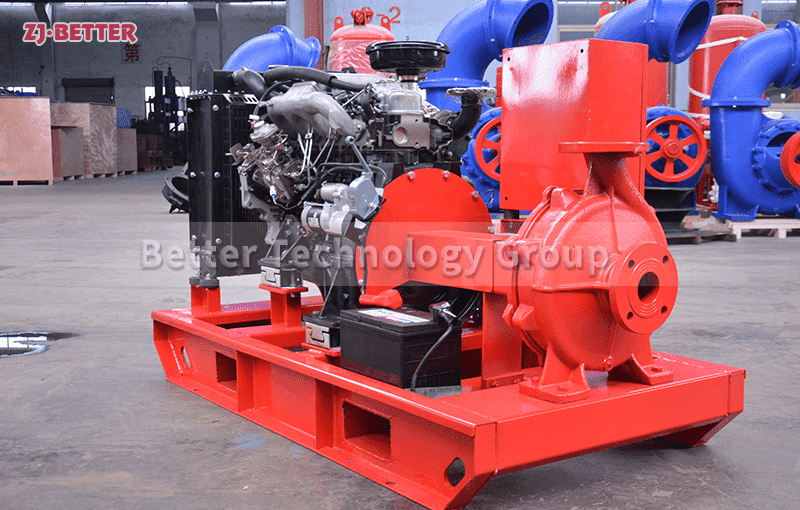

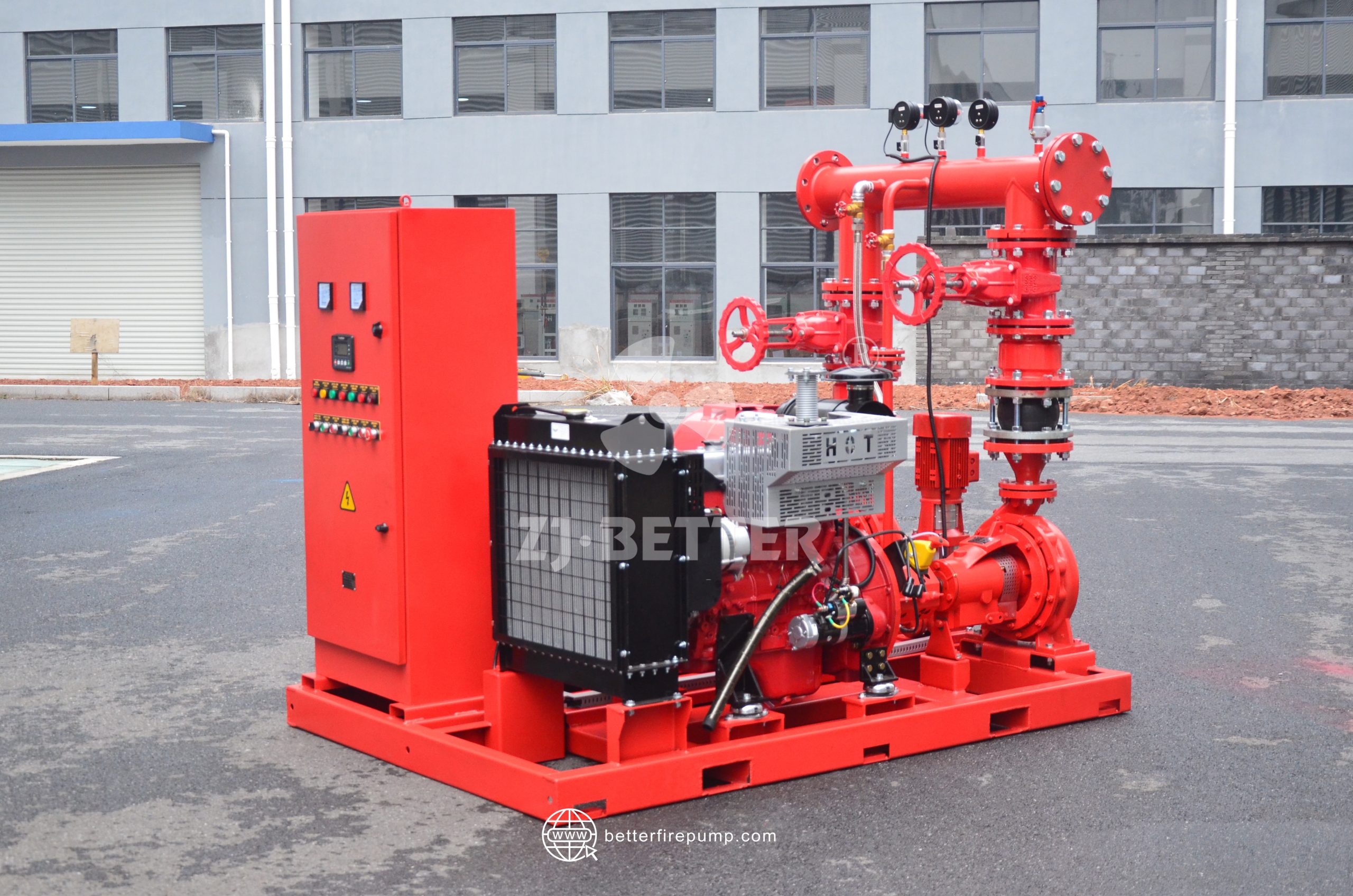

Diesel-driven water pumps, as indispensable core power equipment in modern fire protection systems, play a crucial role in responding to sudden fires, pipe bursts, water transportation, and other emergency tasks due to their powerful, stable, and sustainable operation. Compared to traditional electric water pumps that rely on external power, diesel-driven water pumps significantly improve rescue efficiency in critical moments due to their independent power, self-powered operation, rapid start-up, high flow rate, and high head. They are particularly prominent in fire protection systems in industrial parks, oil fields, construction sites, storage centers, locations far from municipal power grids, and large building complexes. Because diesel engines have strong torque output and excellent durability, diesel water pumps can maintain stable water pressure and flow under prolonged high-load operation. This characteristic makes them especially suitable for demanding conditions in fire protection missions requiring continuous pumping, long-distance water transportation, and multi-point high-pressure water supply. The core structure of these devices mostly adopts high-strength cast iron pump bodies, wear-resistant impeller designs, sealing protection systems, and stable coupling structures, ensuring stable hydraulic performance even when facing corrosive liquids, sandy water sources, or complex field environments. Diesel engines possess excellent combustion efficiency and energy utilization, providing high power to drive pump units at high speeds while ensuring low fuel consumption and high durability. They also effectively reduce the risk of overheating during prolonged operation, helping the equipment maintain stable performance in continuous water supply tasks. In actual rescue scenarios, the high temperatures, power outages, damaged wiring, and harsh environments at fire scenes often render electric pumps unusable. Diesel water pumps, however, with their advantage of requiring no electricity and only fuel, become the most reliable water supply equipment at emergency sites. Their rapid start-up system typically ignites and enters working status within seconds, allowing rescuers to quickly engage in firefighting operations in emergencies, effectively reducing the initial spread of fire and improving overall firefighting efficiency. The head performance of diesel-driven water pumps is also a significant advantage. Relying on high-speed power output, they can provide strong drainage pressure, allowing water jets to cover higher floors and greater distances, playing an irreplaceable role in high-rise buildings, automated warehouses, chemical plants, and large industrial structures. Many models employ a multi-stage impeller structure, achieving stable high-lift output through step-by-step pressurization, maintaining reliable performance even under long-distance water conveyance and high-pressure water supply tasks. Their wide flow range adapts to various scales of firefighting needs, flexibly meeting the demands of rapid fire suppression in small to medium-sized scenarios or large-scale industrial firefighting operations. In addition to their powerful performance, diesel-driven water pumps also offer significant advantages in environmental resistance. They typically feature rainproof covers, heat insulation covers, dustproof structures, thickened bases, and corrosion-resistant materials, enabling them to withstand complex conditions such as high temperatures, low temperatures, humidity, dust storms, rain, snow, and oil/gas environments. Many pump sets are also equipped with vibration-damping bases, maintaining low vibration levels in the diesel engine during high-speed operation, thereby extending the pump body’s structural life and reducing the risk of loosening of connecting components. The equipment’s fuel system often features dual fuel filters to ensure fuel purity and effectively reduce the failure rate of the combustion system. The cooling system employs air-cooled or water-cooled structures, continuously cooling the engine under prolonged high loads. The lubrication system boasts efficient circulation capabilities, reducing friction loss and extending engine life. The exhaust system is designed for quiet operation, minimizing noise pollution while ensuring power output, facilitating operation in urban or industrial areas. Many diesel water pumps also integrate automatic monitoring systems that monitor key data such as speed, oil pressure, water temperature, operating time, pressure changes, and flow status in real time. In case of abnormalities, such as low oil pressure, excessively high temperature, or abnormal load fluctuations, the system will automatically issue an alarm or automatically shut down for protection, preventing equipment damage and ensuring the safety of on-site personnel. This intelligent monitoring not only enhances equipment safety but also significantly reduces the probability of malfunctions caused by improper operation, making rescue operations more efficient and stable. In addition, some diesel water pumps support remote monitoring or linkage control, and can be connected to sprinkler systems, wet alarm valves, fire hydrant systems, or online control platforms in fire protection systems to achieve automatic start-up and timed inspection functions, ensuring that the system can automatically start operation in the event of a fire and improving the overall response speed of the fire protection system. Diesel-driven water pumps offer flexible installation options, including base-mounted, trailer-mounted, box-type protective structures, or enclosed units, suitable for various environments. Mobile designs allow for rapid deployment outdoors, in mountainous areas, forests, reservoirs, or areas far from fire water sources, greatly facilitating field firefighting, water source transfer, or large-scale infrastructure rescue. Fixed installations are suitable for fire pump rooms, factories, warehouses, building basements, etc., and can operate as the main or backup pump in a fire protection system. Some units can also form a dual-power system with electric fire pumps to ensure that the fire protection level of urban buildings meets standard requirements, maintaining continuous water supply even in the event of a main power outage. The maintenance cost of diesel-driven water pumps is relatively controllable, with a mature and stable structure and simple maintenance and operation. Regularly changing the engine oil, fuel filter, and air filter, and checking the cooling system are sufficient to maintain stable operation for extended periods. The pump body only requires periodic checks of the seals and impeller wear, requiring no complex maintenance. Furthermore, the use of corrosion-resistant alloy materials allows it to operate for many years under normal water quality conditions without serious damage, significantly reducing long-term maintenance costs. For businesses, construction sites, municipal units, and fire protection system operators, diesel-driven water pumps offer long service life, stable performance, and strong environmental adaptability, effectively reducing equipment usage risks and improving overall fire emergency response capabilities, making them a long-term and reliable investment. In summary, diesel-driven water pumps, with their strong continuous operation capability, excellent flow and head performance, rapid start-up, energy self-sufficiency, strong environmental adaptability, high safety and reliability, and easy maintenance, have become an important power source for various fire protection systems. In the face of fire accidents or other emergencies, they can maintain stable operation in environments without electricity or under harsh conditions, providing continuous and powerful hydraulic support for rescue operations, thereby significantly improving firefighting efficiency and overall rescue performance. Its superior performance characteristics make it suitable not only for urban building fire protection, but also for factories, warehouses, oil fields, mines, forests, outdoor facilities and various remote areas, building a safer and more reliable fire protection system for users. It is an important and irreplaceable key equipment in the modern emergency equipment system.