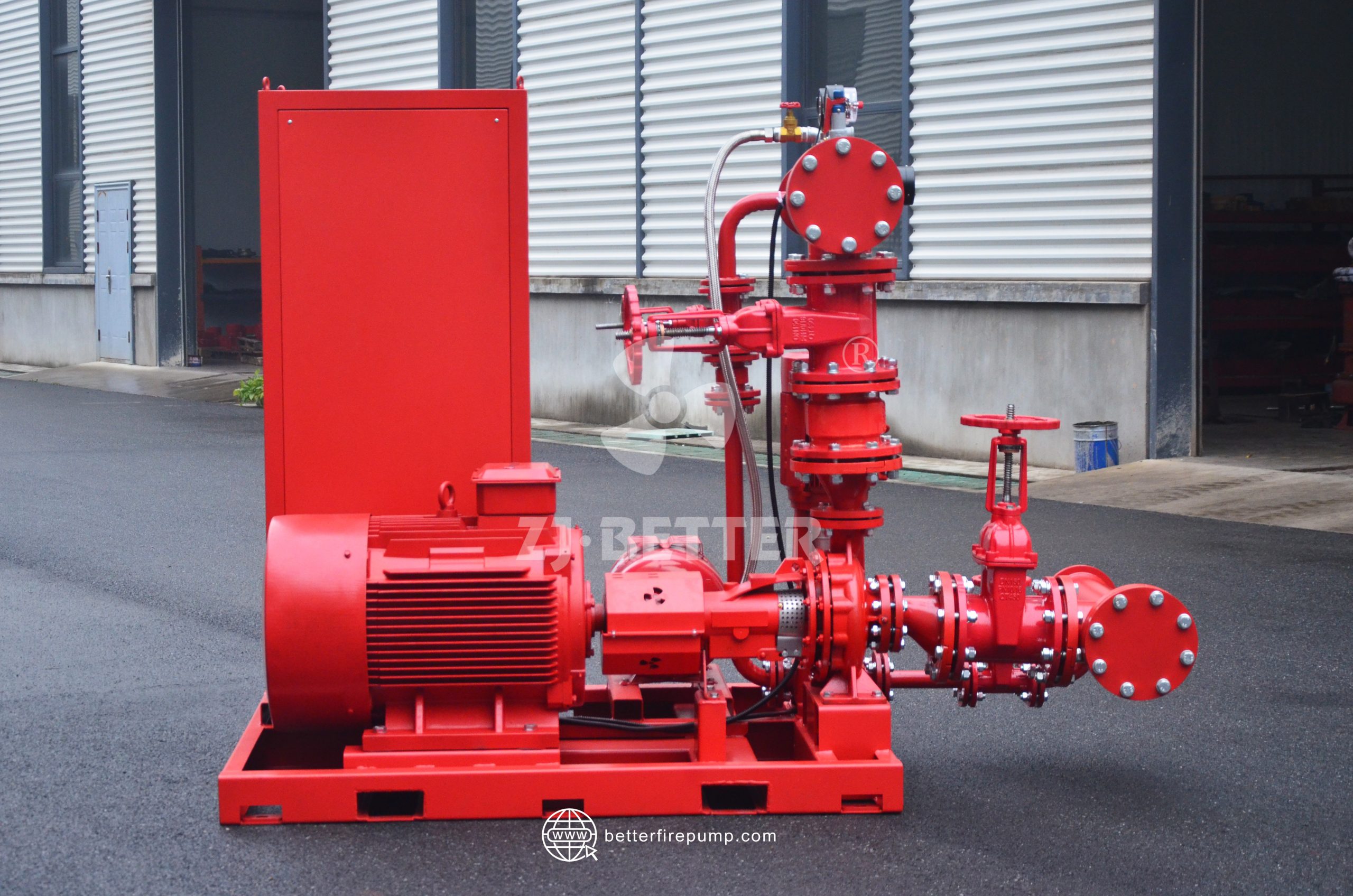

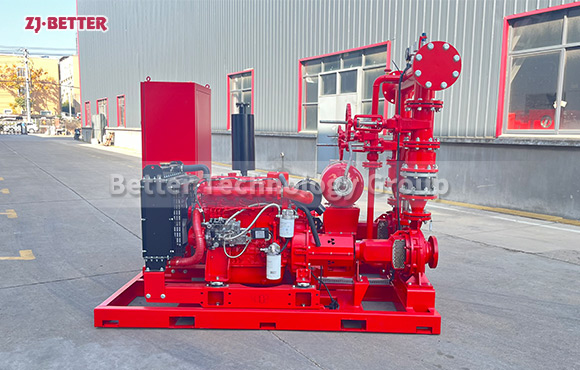

Multistage Booster Fire Pump: Essential Equipment for Long-Distance Water Delivery and High-Head Fire Applications

High-pressure multistage fire pump designed for long-distance and high-rise fire protection, offering stable pressure, high efficiency, durable construction, and reliable emergency performance for industrial, commercial, and municipal fire systems.

Multistage booster fire pumps are core fire-fighting equipment specifically designed for high-lift, long-distance fire water supply scenarios. They are structurally stable, operate efficiently, and provide continuous and reliable pressure output. They play an irreplaceable role in high-rise buildings, large factories, chemical plants, warehousing and logistics centers, pump station renovation projects, and fire-fighting systems requiring long-distance water delivery. These devices employ a multi-stage series impeller structure, achieving a head capacity far exceeding that of ordinary centrifugal pumps by progressively increasing pressure at each stage. This allows the system to maintain a stable water supply even under conditions of significant pressure drop, long water delivery distances, high building heights, or dispersed fire-fighting water points. This ensures a sufficient and powerful water flow for the fire-fighting system in emergencies, thereby significantly enhancing the overall reliability of the fire-fighting system and the efficiency of on-site fire suppression. The core advantages of multi-stage booster fire pumps are primarily reflected in their high head output capacity. Their multi-stage impeller design, which progressively pressurizes the water in stages, allows them to easily achieve head ranges from tens to hundreds of meters. This makes them suitable for projects requiring overcoming height differences or ultra-long water delivery distances. In high-rise buildings, they can stably deliver water to the top fire station, while in large factory areas, they can maintain consistent water pressure over long distances, providing stable pipeline pressure support for fire protection systems. Simultaneously, the hydraulic model of this type of pump is optimized, ensuring high efficiency even at high head operation, reducing energy loss and improving overall water efficiency. Secondly, multi-stage booster fire pumps exhibit significant operational stability and high reliability. Their modular design means that the impeller, pump casing, and shaft assembly are all precision-machined and dynamically balanced, ensuring low vibration and low noise during high-speed operation, minimizing mechanical wear, and extending the overall lifespan of the equipment. The pump shaft is typically made of high-strength alloy steel or stainless steel, offering strong corrosion resistance and suitability for various water quality environments, maintaining stable performance even in acidic, alkaline, or environments with high impurity content. The shaft seal employs a mechanical seal or double-end face seal structure, effectively preventing leakage and ensuring safe and reliable operation even after extended periods. Furthermore, the multi-stage booster fire pump boasts robust motor configurations. Its motors typically utilize high-grade insulation systems, featuring high starting torque, high temperature resistance, and strong continuous operation capability, enabling stable operation under conditions of high fire-fighting start-up loads, strong power grid fluctuations, or frequent emergency starts. Additionally, some systems can be equipped with soft-start devices or frequency converters, making pump startup smoother, reducing impact on the power grid, and preventing system tripping or startup failure due to excessive instantaneous current, further enhancing the overall system reliability and protection level. The material selection of the multi-stage booster fire pump is also a crucial component of its advantages. The pump body is generally made of high-strength pressure-resistant cast iron, ductile iron, or stainless steel, with different material combinations available depending on the operating environment to ensure the pump body can withstand high pressure and high flow velocity impacts for extended periods without deformation or damage. Some components, such as the impeller and pump shaft, can also be made of stainless steel or copper alloy, further enhancing corrosion resistance and wear resistance, extending the service life of the equipment in actual engineering environments. Its internal flow channels have undergone multiple optimizations, resulting in lower water flow resistance and higher efficiency, thereby reducing energy consumption and improving the overall economic efficiency of the machine. Multi-stage booster fire pumps also offer significant advantages in installation and maintenance. Their stable base structure allows for precise coaxial installation of the motor and pump body, reducing on-site commissioning difficulties and making them suitable for both new construction projects and the upgrading of existing pump stations. The equipment typically uses a coupling connection structure, facilitating disassembly and maintenance, allowing for quick replacement of vulnerable parts, and maintenance without disassembling the entire machine. This significantly saves maintenance time, reduces downtime, and keeps the fire protection system in a state of constant readiness. This is especially crucial for fire protection projects with extremely high reliability requirements. Furthermore, these pumps support integrated operation with various fire control systems, automatically starting or stopping based on changes in pipeline pressure. When used in conjunction with pressure switches, automatic control cabinets, or fire alarm systems, they can achieve fully automatic operation, ensuring the pump can be deployed immediately in the event of a fire. Its control system typically offers manual, automatic, and remote control modes to meet the management flexibility requirements of various projects. It also features multiple protection functions, such as phase loss protection, overload protection, overcurrent protection, and over-temperature protection, ensuring safe equipment operation and preventing pump damage or system failure due to malfunctions. Multistage booster fire pumps demonstrate extremely high applicability in practical applications. Whether in high-rise buildings, elevated warehouses, underground facilities, tunnel fire stations, mining fire water supply, dock and port fire protection, or in petrochemical, heavy industrial manufacturing, large cold storage, and logistics parks, it can provide strong, stable, and continuous high-pressure water supply capabilities. Especially in long-distance water transmission projects, multistage booster fire pumps, with their high-pressure output and low water pressure attenuation characteristics, are the most suitable solution, effectively compensating for the limitations of ordinary single-stage fire pumps that cannot meet the requirements due to insufficient head. Furthermore, in scenarios requiring increased pressure in existing pipe networks, multi-stage booster fire pumps can also be used as booster units. By increasing pipe network pressure, they meet the operational requirements of various fire-fighting equipment such as sprinkler systems, fire hydrant systems, and deluge systems, making the entire fire protection system operate more coordinated, efficient, and safe. For modern fire protection systems that prioritize low energy consumption, low maintenance, and high stability, multi-stage booster fire pumps, due to their highly mature design technology, sustainable operation capabilities, and strong environmental adaptability, have become a preferred key equipment in many fire protection projects. Their manufacturing strictly adheres to fire protection standards and quality systems, ensuring that every step meets industrial-grade durability and safety standards, providing users with long-term reliable fire water supply. Overall, multi-stage booster fire pumps, with their high head, high efficiency, compact structure, stable operation, convenient installation, simple maintenance, and strong adaptability, occupy an extremely important position in the current fire water supply field, providing a reliable water supply foundation for various fire protection systems. Whether in harsh industrial environments or in modern buildings where water supply stability is extremely important, it can provide stable fire pressure support with its superior performance and strong adaptability, ensuring that fire water supply tasks can be carried out quickly and effectively in emergencies, and providing solid fire safety protection for all types of buildings and facilities.

.jpg)