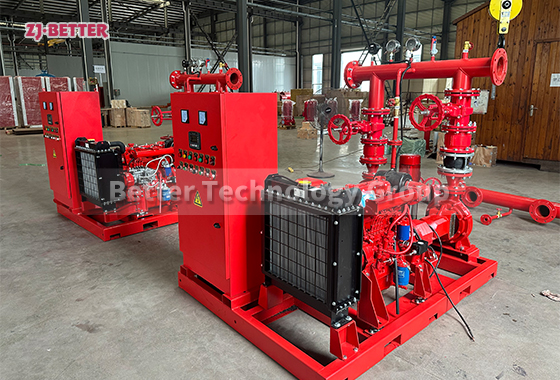

Fire pump standby power diesel generator set

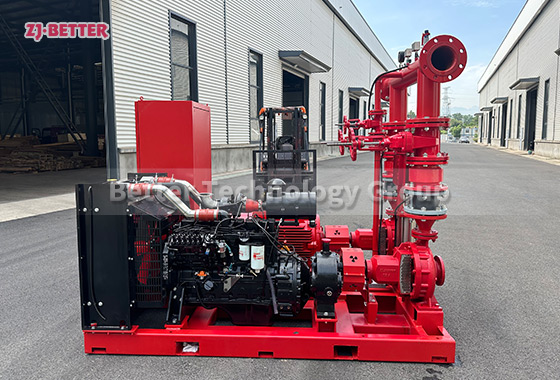

One way of choosing a diesel generator as a backup power source for fire protection is because in fire protection, two power supplies are required, which can be two power plants and two transformers, or one line of city power and one line of diesel generator set power supply. Meet the requirements of fire backup power.

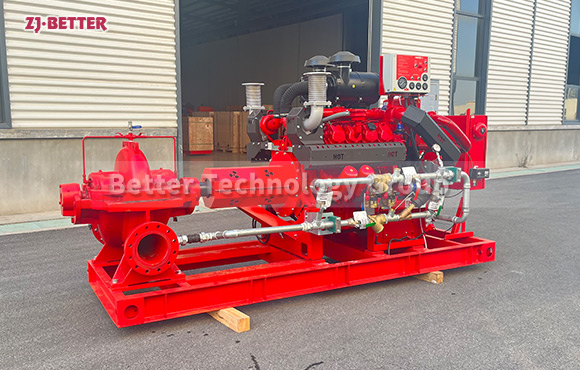

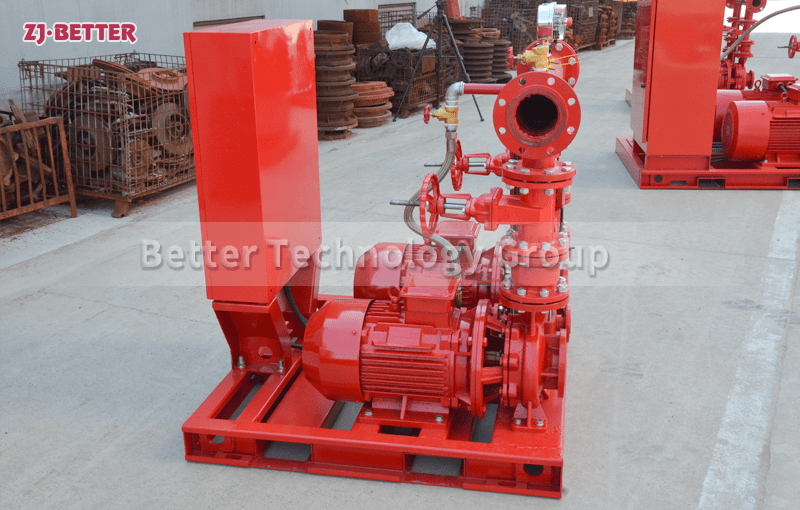

After receiving fire/pipe network pressure/power failure/other starting signals, the diesel engine fire pump can automatically start within 5 seconds and enter into full-load operation. The battery can be automatically charged by the main power supply or the diesel charging motor to ensure the smooth start of the equipment; the diesel engine will automatically alarm and protect the low oil pressure, high water temperature and other faults, and the overspeed alarm will stop; the diesel engine fire pump will be in the thermal standby state to ensure emergency work. The diesel engine fire pump adopts the direct connection technology between the diesel engine and the water pump. Through the elastic coupling, the failure points are reduced, the start-up time of the unit is greatly shortened, and the reliability and emergency performance of the unit are improved.