Efficient Deep Well Firefighting Solution: Advantages of Diesel Engine Vertical Long Shaft Fire Pump

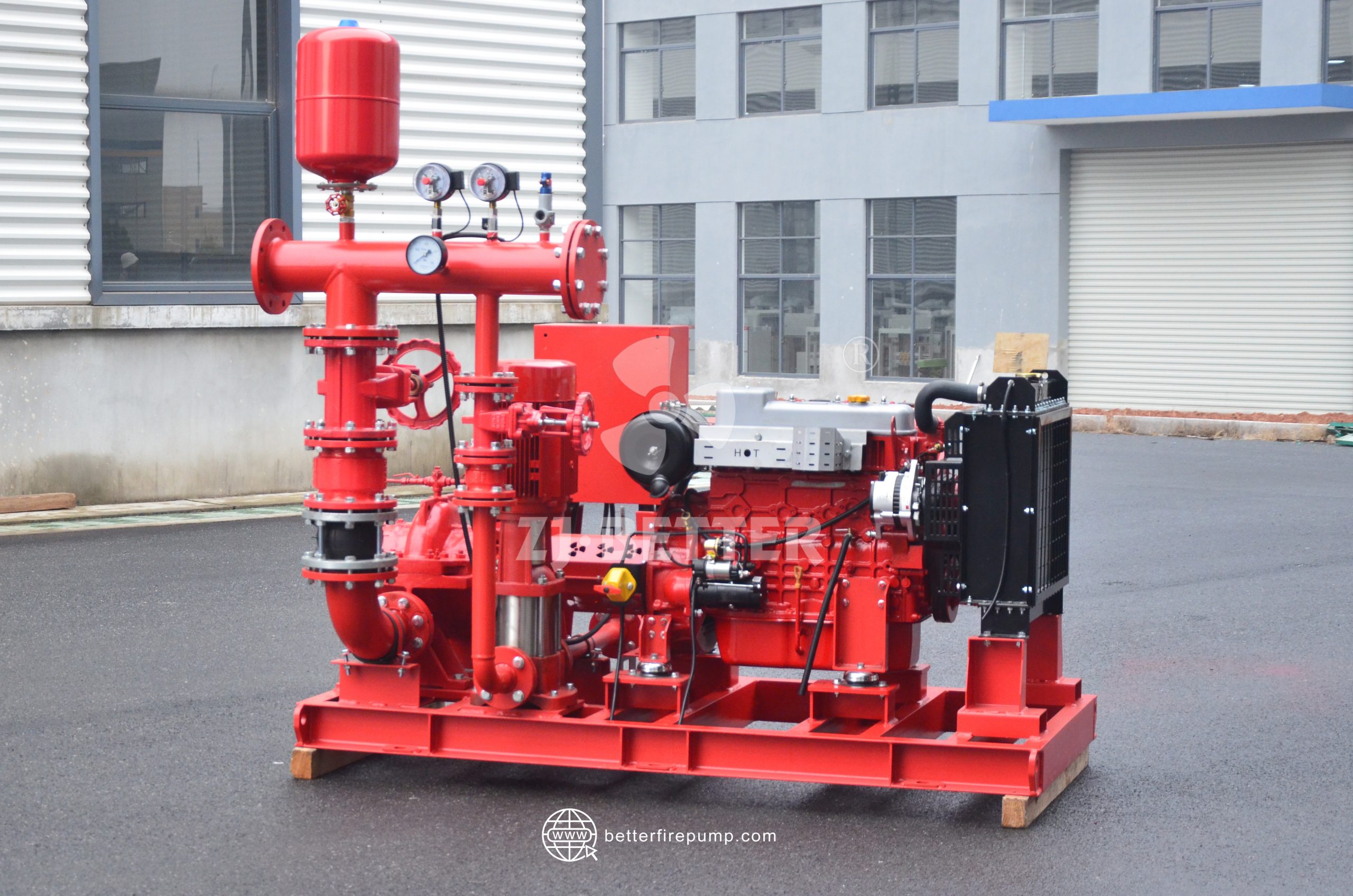

This diesel engine-driven vertical long shaft fire pump is designed specifically for deep well water extraction and high-lift water supply applications, making it ideal for industrial zones, petrochemical plants, power stations, and remote areas without municipal water sources. Its key advantage lies in combining powerful diesel drive with a vertical multistage pump structure to deliver efficient fire protection without reliance on electricity.

The unit features a modular design, directly coupling the diesel engine and pump body for high transmission efficiency and quick response. The long shaft construction allows the pump to reach deep underground water sources, greatly enhancing flexibility in resource access. With its compact structure, easy maintenance, and stable operation, this pump is especially suitable for high-rise buildings, large storage facilities, and ports where fire safety demands are critical.

As the core component of deep-well fire protection systems, this diesel vertical shaft pump offers outstanding reliability, adaptability, and energy efficiency, making it a top solution for challenging fire scenarios.

We are a modern enterprise specializing in the research, development, and manufacturing of fire pump systems, committed to delivering stable and reliable fire water supply solutions to clients worldwide. Our extensive product range includes diesel engine fire pumps, electric fire pumps, constant pressure water supply systems, control panels, and complete pump sets. These systems are widely used in high-rise buildings, industrial plants, petrochemical facilities, power stations, and municipal infrastructure projects.

Equipped with advanced production machinery and a rigorous quality management system, we have established a complete production chain from design and parts processing to final assembly and testing. Every unit undergoes strict performance tests before leaving the factory to ensure reliable operation in critical emergency situations. With a strong focus on innovation, we continuously adopt cutting-edge technologies to enhance our products’ efficiency and intelligent control capabilities.

Our products have been successfully exported to dozens of countries including Southeast Asia, the Middle East, South America, and Africa. They have been widely applied in major engineering projects and earned consistent praise from our clients. Upholding the principle of “Safety First, Quality Always,” we are committed to becoming a globally trusted name in the field of fire pump systems.