How to Protect Fire Pumps in Cold Climates

Learn the essential steps to protect fire pumps from freezing and malfunction during winter, ensuring reliable fire protection in cold environments.

Fire pumps are a building’s first line of defense in the event of a fire. However, in cold climates, freezing temperatures can severely impact the operation and reliability of fire pump systems. Frozen pipes, cracked pump housings, and impaired controllers can lead to costly repairs—or worse, failure during an emergency.

This article covers practical strategies to protect fire pumps in cold climates and ensure uninterrupted fire protection all winter long.

1. Install the Pump Indoors or in Heated Enclosures

The best way to protect fire pumps from freezing is to house them in a heated pump room or enclosure. According to NFPA 20, fire pumps must be protected from temperature extremes and should ideally be installed in a fire-rated, insulated, and climate-controlled room.

If indoor installation is not possible, use outdoor fire pump enclosures specifically designed for cold weather. These enclosures should include:

-

Thermal insulation

-

Built-in space heaters

-

Weatherproof construction

-

Emergency lighting and ventilation

2. Maintain Minimum Temperature in Pump Room

To prevent freezing, maintain a consistent room temperature of at least 40°F (4°C) or higher, especially around the pump, controller, and piping. Use thermostatically controlled unit heaters or radiant heaters for efficiency.

Consider installing temperature sensors with remote monitoring so facility managers can receive alerts if the temperature drops below a safe threshold.

3. Insulate and Heat Piping

All suction, discharge, and test header lines that are exposed to the cold should be:

-

Wrapped with thermal insulation

-

Fitted with electric heat tracing cables (self-regulating preferred)

-

Protected with weather-resistant cladding

Focus on elbows, valves, and fittings—these are most susceptible to freezing due to their thinner walls and complex shapes.

4. Use Anti-Freeze Loops or Glycerin Mixtures (if code allows)

In some cases, especially where small portions of pipe are exposed to freezing temperatures, anti-freeze loops may be used. This involves circulating a non-toxic glycol mixture through a closed-loop system.

However, per NFPA 13 and local codes, anti-freeze use is strictly regulated and may not be allowed in some sprinkler systems unless the mixture is listed for use. Always confirm with your local authority having jurisdiction (AHJ) before using.

5. Drain Test Headers and Unused Piping

After conducting a fire pump flow test or any maintenance involving water discharge, immediately drain all external piping. Water left inside exposed pipes or test headers can freeze, expand, and burst the piping.

Install drain valves at low points to facilitate quick draining. Use signage or SOPs to remind staff to drain pipes after every test.

6. Inspect and Maintain Regularly During Winter

Cold weather requires more frequent checks. Implement a winter maintenance checklist including:

-

Verifying heater operation and thermostat settings

-

Checking insulation integrity

-

Confirming no ice buildup around the pump or piping

-

Testing pump controller for reliable startup

-

Running a weekly churn test to ensure readiness

Document each inspection to track issues before they become emergencies.

7. Use Diesel Engine Cold-Weather Kits

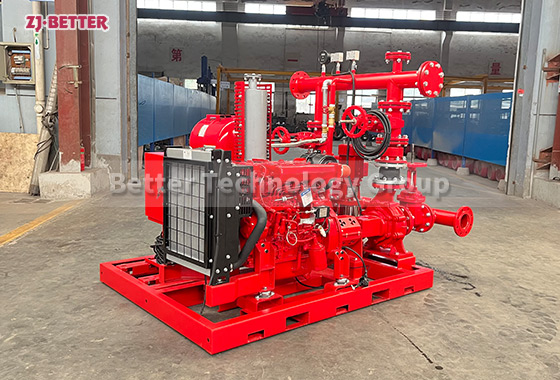

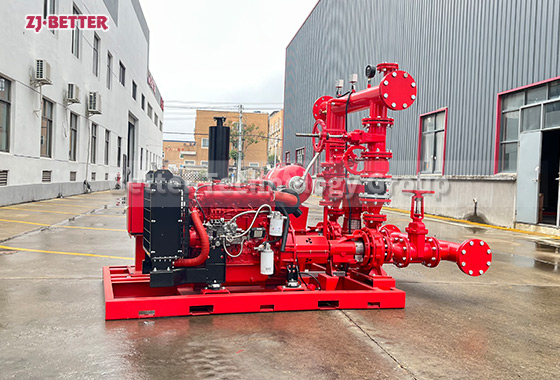

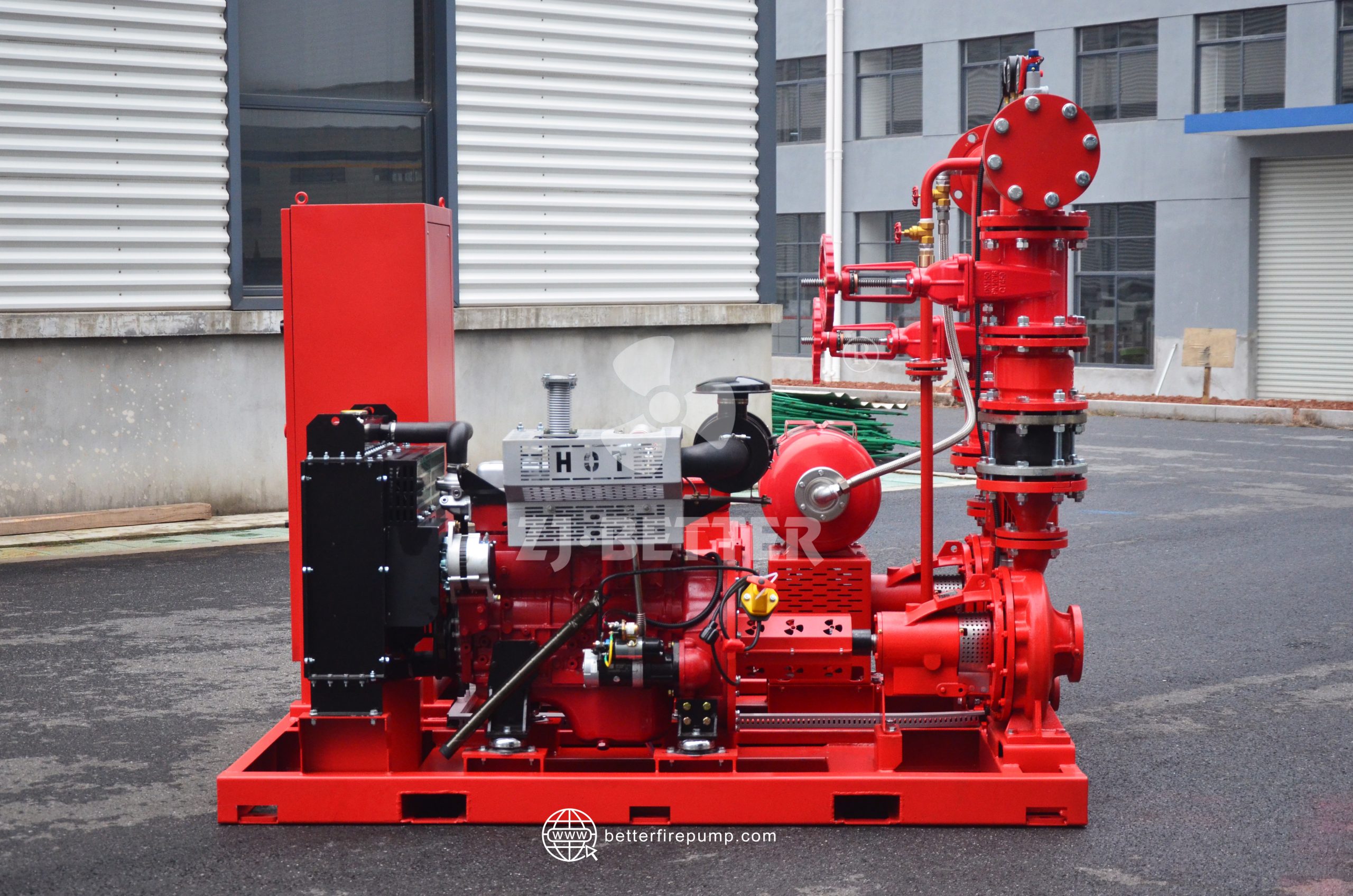

For diesel engine fire pumps, cold starts can be challenging. Equip diesel engines with:

-

Block heaters to keep engine coolant warm

-

Battery warmers for reliable cranking power

-

Glow plugs or intake air heaters to assist combustion

-

Winter-grade diesel fuel to prevent gelling

These accessories are often available as part of cold-climate diesel pump packages and are critical for winter operation.

8. Ensure Backup Power in Extreme Weather

Winter storms can lead to power outages. If you use electric fire pumps, ensure they are connected to:

-

Emergency generators

-

Automatic transfer switches (ATS)

-

Battery-backed control systems

This ensures the pump remains operational even during blackouts caused by snow, ice, or windstorms.

Conclusion

Cold climates pose serious risks to fire pump systems, but with proper design, insulation, heating, and maintenance, these systems can operate reliably throughout the winter. Protecting your fire pump from freezing is not just about compliance—it’s about ensuring that lifesaving equipment performs when it’s needed most.

Prepare early, inspect regularly, and invest in winter-ready components to avoid damage, downtime, and fire safety risks during cold weather.