How to Integrate Fire Pumps with Sprinkler Systems

Learn how to properly integrate fire pumps with sprinkler systems to ensure consistent pressure, compliance with NFPA standards, and reliable fire protection.

Fire sprinkler systems are a critical component of building safety, designed to suppress or control fires automatically. However, to function effectively, especially in high-rise buildings or facilities with high water demand, these systems often require a fire pump to maintain adequate pressure and flow. Integrating a fire pump with a sprinkler system is not only a matter of engineering—it’s a necessity for reliable fire protection.

This article outlines how to properly integrate fire pumps with sprinkler systems, the key design considerations, and how to ensure compliance with applicable codes.

1. Understand the Role of the Fire Pump

A fire pump boosts the water pressure in the sprinkler system when the available water supply (from a municipal source or storage tank) is insufficient. Fire pumps are activated automatically when a pressure drop is detected in the system, which typically happens when one or more sprinkler heads open in response to heat.

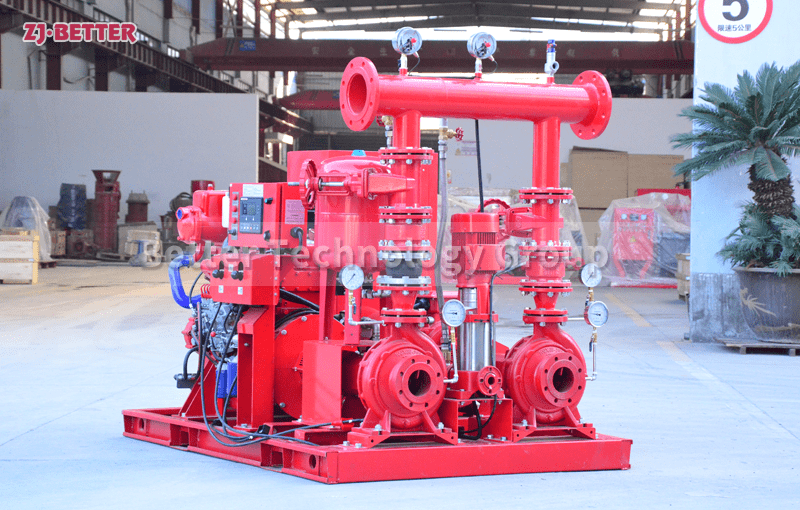

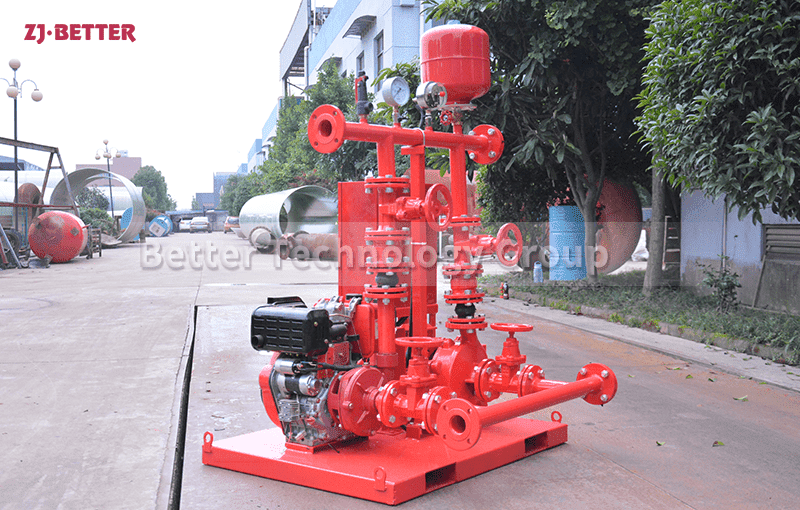

The most common types of fire pumps used with sprinkler systems include:

-

Horizontal split-case pumps

-

Vertical inline pumps

-

End suction pumps

-

Vertical turbine pumps (for deep wells or open water sources)

2. Evaluate System Demand

Before integrating a fire pump, you need to assess the specific demands of the sprinkler system. This includes:

-

System flow rate (GPM): Determined by the size of the protected area and the type of hazard (light, ordinary, or high hazard).

-

System pressure (PSI or bar): Based on the building height, pipe friction loss, and pressure required at the most remote sprinkler head.

A hydraulic calculation must be performed to determine the total pressure required. The selected fire pump must be capable of delivering this flow and pressure according to NFPA 20 and NFPA 13 requirements.

3. Coordinate with NFPA Standards

NFPA 20 governs the installation of fire pumps, while NFPA 13 covers the design and installation of sprinkler systems. Integration of both systems must follow:

-

NFPA 20: Ensures proper pump selection, controller settings, alarm integration, and test headers.

-

NFPA 13: Defines sprinkler demand, pipe sizing, and minimum discharge criteria.

It’s critical that the fire pump provides water at a pressure that satisfies the sprinkler system’s hydraulic demand curve without exceeding the system’s rated working pressure.

4. Select a Compatible Pump Controller

The fire pump controller is the brain of the operation. It must detect when the sprinkler system’s pressure drops and activate the pump. Integration points include:

-

Automatic start by pressure sensing: The controller receives input from pressure switches connected to the sprinkler system.

-

Remote alarm signals: The controller sends signals to the fire alarm panel when the pump starts or malfunctions.

-

Manual override controls: Allow personnel to start or stop the pump during testing or emergencies.

Controllers must comply with UL 218 and NFPA 20 standards and be suitable for the selected pump type (electric or diesel).

5. Plan for a Reliable Water Supply

The integration must account for a consistent and reliable water source. Options include:

-

City mains: Common but may require a pump due to low pressure or flow limitations.

-

Water storage tanks: Often used in buildings where the municipal supply is unreliable.

-

Rooftop or break tanks: Frequently used in high-rises.

The fire pump must draw water from a supply that meets the system’s required flow rate for the duration of a fire event (usually 60 to 90 minutes or more, depending on regulations).

6. Use Check Valves and Pressure-Relief Devices

To avoid reverse flow and over-pressurization, certain components must be included in the system:

-

Check valves: Prevent backflow into the pump or supply line.

-

Pressure relief valves: Protect the system from overpressure when the pump is running at churn (no-flow) conditions.

-

Pressure maintenance (jockey) pumps: Keep the system pressurized to avoid unnecessary pump starts from small leaks or temperature changes.

These elements help ensure a smooth, reliable integration and prevent premature pump wear.

7. Ensure Electrical Compatibility

For electric-driven fire pumps, ensure the power supply is stable and compliant with local electrical codes. Diesel-driven systems must include proper fuel storage, ventilation, and exhaust systems. Either setup should include:

-

Emergency backup power or generators (if required by code)

-

Pump room lighting and alarms

-

Proper grounding and surge protection

8. Test and Commission the System

Before the integrated system is operational, it must undergo:

-

Acceptance testing: As per NFPA 20 and NFPA 13, verifying flow, pressure, pump operation, and alarm functionality.

-

Annual flow tests: To ensure the pump still meets design criteria over time.

-

Routine inspection and maintenance: Including monthly churn tests, controller tests, and visual inspections.

Regular testing is key to guaranteeing the pump and sprinkler system will perform reliably in a real emergency.

Conclusion

Integrating a fire pump with a sprinkler system is a complex but essential task that ensures your building remains protected under all conditions. It involves careful calculation, adherence to NFPA standards, proper equipment selection, and thorough testing. By working with experienced fire protection engineers and using certified components, you can achieve a seamless and compliant fire pump–sprinkler integration that provides life-saving protection when it matters most.