Smart-Control Fire Pump Package for High-Pressure, High-Flow Firefighting Demands

Explore the performance and advantages of intelligent control fire pump systems designed for high-pressure and large-flow firefighting applications. Ensure reliable water supply, real-time monitoring, and automated emergency response with advanced technology.

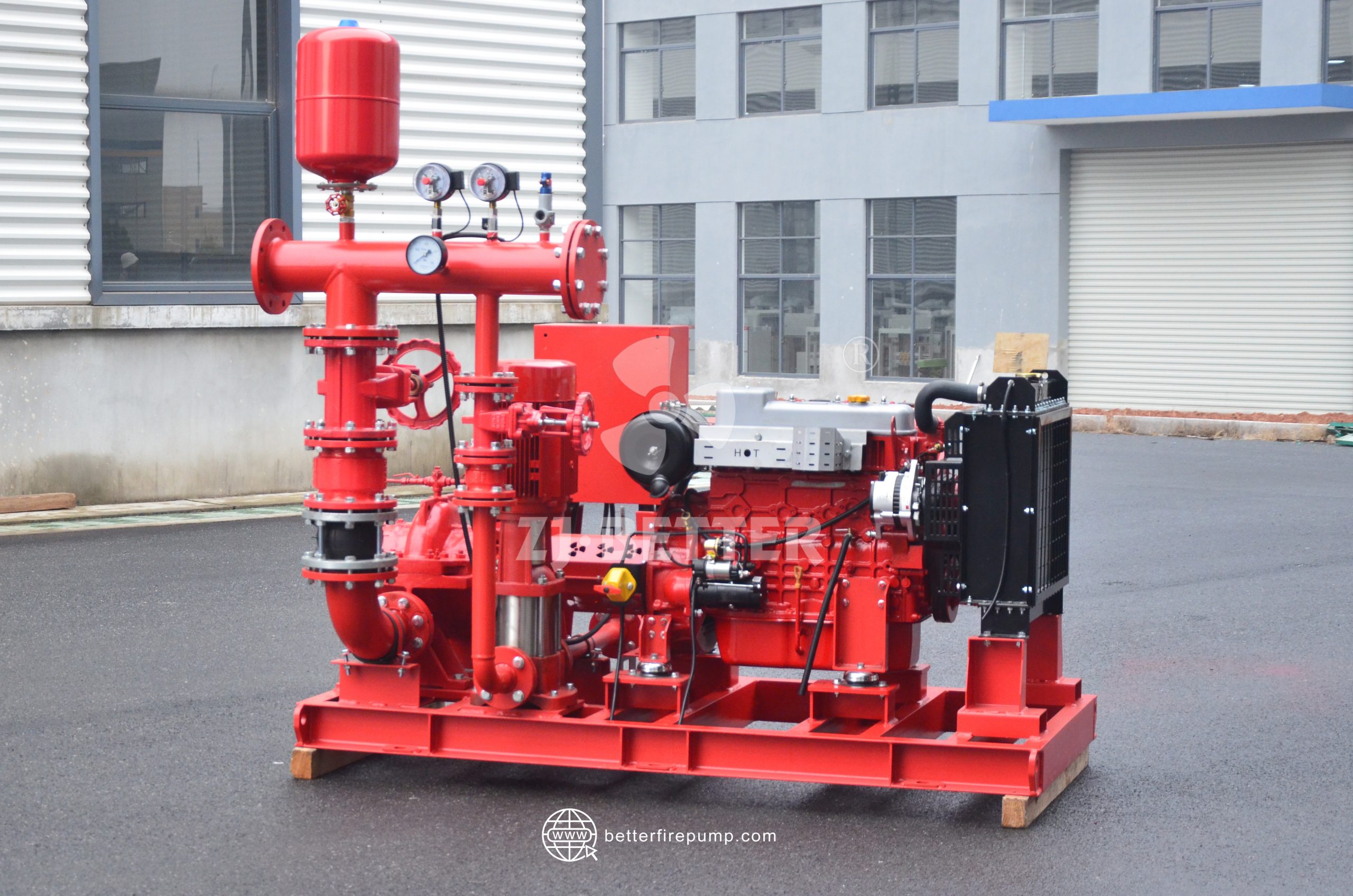

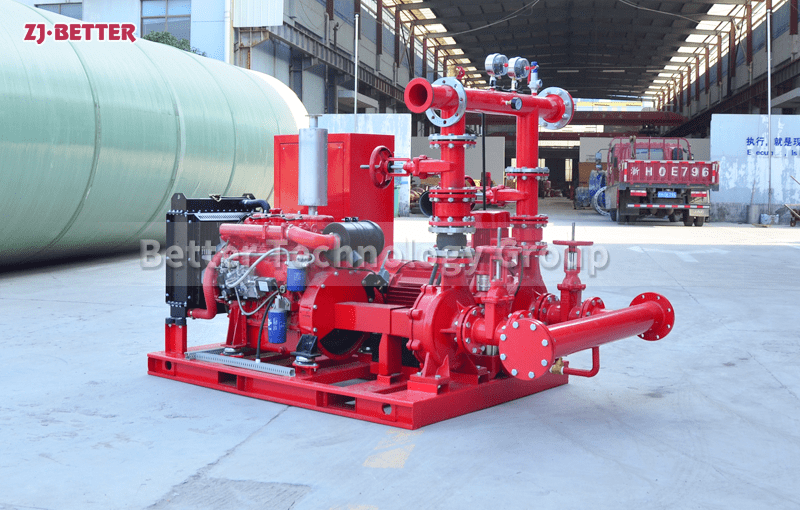

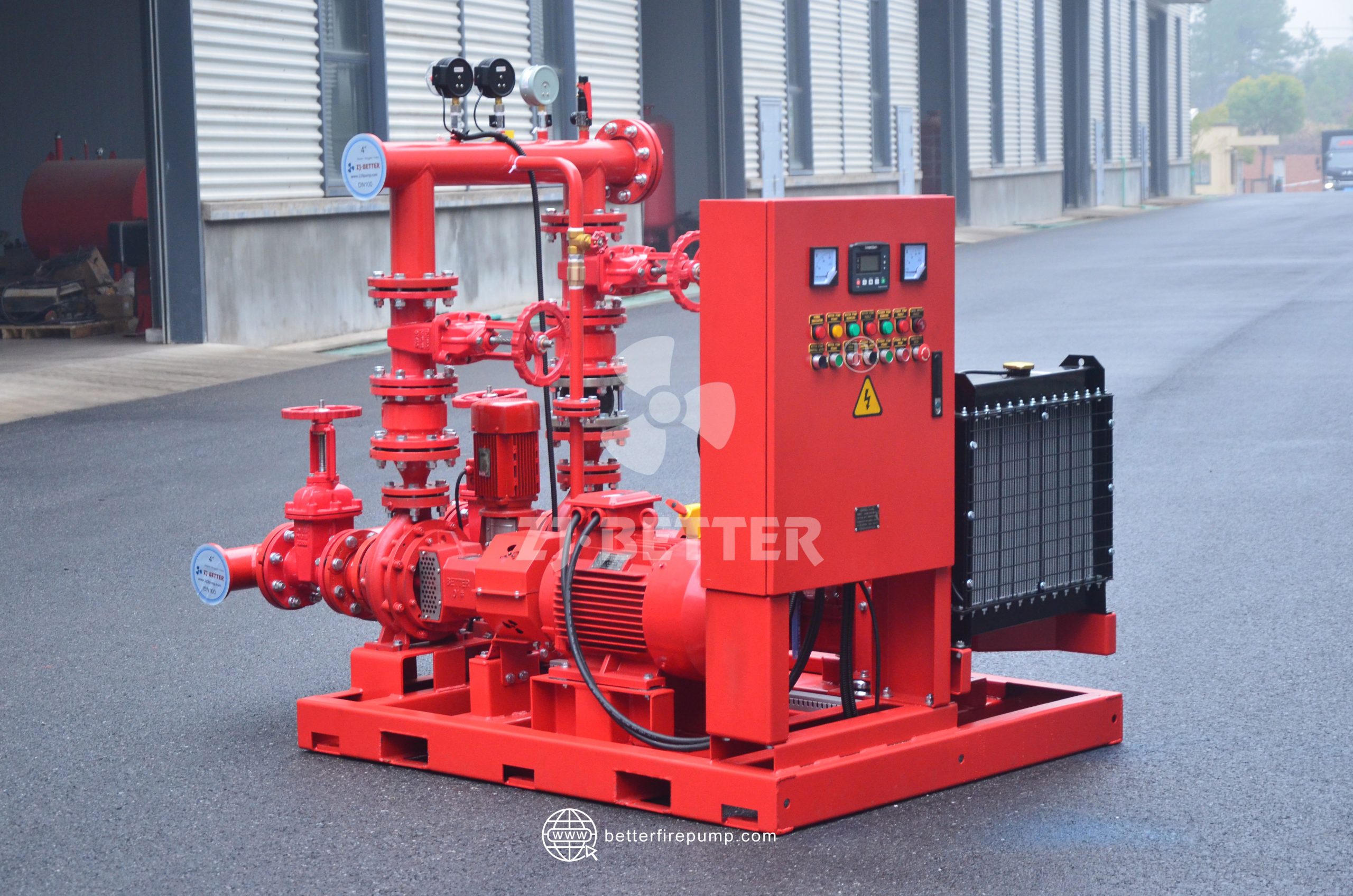

In the context of rapid development of modern urban construction and industrial facilities, fire safety is increasingly valued. Among them, fire pumps are the core equipment to ensure stable water supply at the fire scene, and their performance is directly related to fire extinguishing efficiency and the safety of life and property. As a new type of integrated and highly automated system, intelligent control fire pump units are being widely used in various fire extinguishing scenarios with strict requirements for high pressure and large flow. This type of unit is usually composed of multiple subsystems such as electric or diesel driven main pumps, efficient control systems, pressure stabilizing devices, suction and discharge pipelines, pressure gauges, safety valves, etc., and through coordinated operation, it realizes fully automatic start and stop, pressure regulation and abnormal alarm functions, thereby ensuring rapid response and long-term stable water supply in emergency situations. Compared with traditional fire pump systems, intelligent control fire pump units have achieved a qualitative leap in automation, operating efficiency, energy utilization, safety protection, etc. Its biggest feature is the introduction of the “intelligent control” module. The system can monitor the operating status of the pump unit in real time and automatically adjust according to on-site needs through core components such as built-in PLC program controllers, pressure sensors, water level detectors, and remote data communication interfaces. After a fire alarm occurs in a building, the system can instantly receive a start signal from the fire alarm system, automatically start the main pump, and automatically stop running after detecting that the pipe network pressure has risen, thereby greatly saving manpower and reducing the risk of misoperation. In terms of large-flow water supply, the pump unit usually uses a high-power drive source combined with an efficient single-stage or multi-stage centrifugal pump to achieve the required flow output in a short time. At the same time, the pipeline system and interface use flange connections or quick connectors for easy installation and on-site maintenance. In addition, the pump body is mostly made of ductile iron, stainless steel or carbon steel, combined with a high-temperature resistant mechanical seal structure, making it suitable for complex media such as high temperature, acid and alkali, and containing particles, improving durability and operation stability. In order to adapt to a variety of working environments, the unit is also equipped with an electric control box or a diesel control cabinet, which integrates overload protection, phase loss protection, water pressure abnormality alarm and other functions. Some systems can also be connected to the BMS building control platform to achieve remote start, data upload and equipment linkage. In terms of energy optimization, the unit supports automatic switching between mains and diesel power. When the main power fails, it can quickly switch to the backup diesel system without manual intervention to ensure continuous water supply. The base of the unit is welded with an integral steel structure, which has high-strength shockproof ability. Shock pads or spring isolators can be installed at the bottom to meet the needs of high-rise building floors. In terms of service life, the intelligent control pump unit has a good maintenance interface design, and all core components are installed in a modular manner, which is convenient for later disassembly and replacement. The system also supports a regular self-check function, which can automatically start the pump body at a low speed for a short-term operation inspection according to the set time, so as to detect potential faults in advance and avoid startup failures due to rust, jamming and other reasons of the pump body. In addition, to further reduce noise pollution, the unit can be equipped with a soundproof cover or silencer, which is suitable for places such as hospitals, schools, and libraries that have strict control requirements for environmental noise. Due to its strong adaptability, the intelligent pump unit is widely used in petrochemical plants, large storage and logistics parks, high-rise complexes, airports and subways, etc., which have extremely high requirements for the reliability of fire protection systems. In these applications, the intelligent fire pump unit is usually the core component of the building fire protection system, responsible for quickly providing high-pressure water sources to control and suppress the fire in the early stage of the fire alarm, winning precious time for personnel evacuation and subsequent fire fighting. Some projects will also use a pressure-stabilizing pump and a sprinkler booster pump to form a dual-system linkage mechanism to improve the overall stability of the system and the water supply redundancy capacity. At the same time, the intelligent control fire pump group also supports a variety of certification standards, such as NFPA20, UL, FM and other international certifications, to meet the technical and regulatory requirements of different engineering projects in the global market, and facilitate export and international engineering cooperation. In terms of installation, the manufacturer can provide customized solutions and 3D layout drawings, and flexibly adjust the equipment size, pipeline interface direction, control logic, etc. according to the customer’s project site conditions to ensure the optimal layout in a limited space. It is worth mentioning that the pump group also has good scalability, and can integrate sprinkler systems, foam fire extinguishing devices, fire water tanks, automatic water replenishment pumps and other components as needed to form a complete integrated fire extinguishing platform. In terms of maintenance, the intelligent system can automatically record key data such as operating time, number of starts, water pressure changes, fault codes, etc., to form a complete equipment operation log, and provide strong data support for engineering personnel to troubleshoot and life evaluation in the later stage. Through the remote monitoring platform, managers can view the equipment status in real time on mobile phones or computers, receive fault push notifications, and improve operation and maintenance efficiency. Some systems also support multi-language switching, which is suitable for overseas projects or multinational operation teams. Overall, the intelligent control fire pump unit is a highly integrated, high-performance, and highly stable advanced equipment, which is particularly suitable for high-pressure and high-flow water supply scenarios. It can effectively improve the fire emergency response capabilities of buildings or industrial facilities and reduce the loss of life and property caused by fire. Its stable operation, intelligent monitoring, automatic switching, multiple protections and other advantages make it an indispensable and important part of the current fire protection system, and also one of the important directions for the construction of smart fire protection in the future.