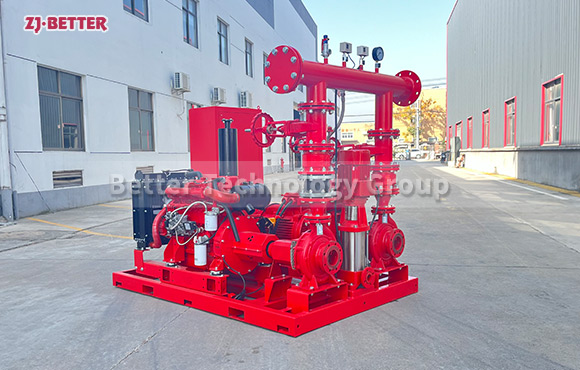

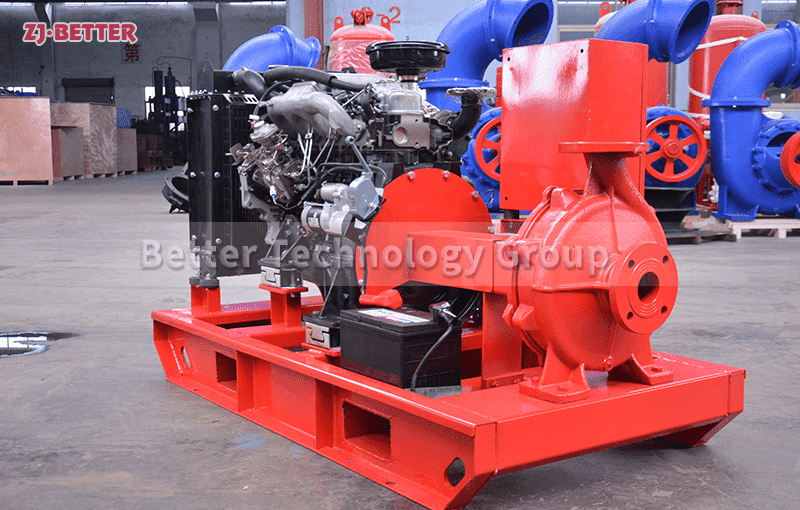

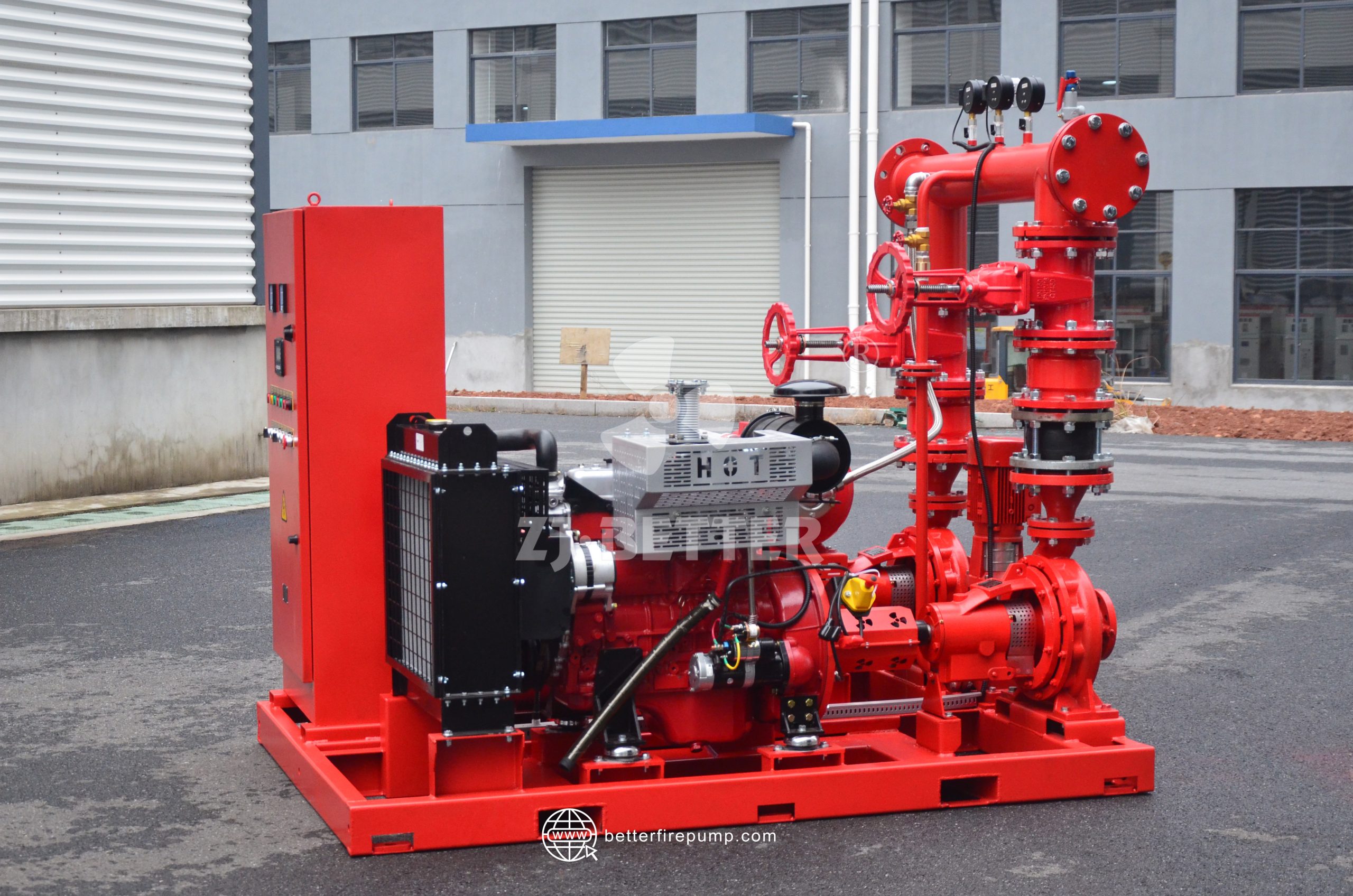

The diesel engine fire pump device is a key equipment designed for emergency water supply in fires. It provides continuous and efficient hydraulic support in an environment where the power supply is unstable or completely interrupted. This diesel engine fire pump system with automatic start-stop control not only continues the high stability and anti-interference performance of traditional diesel power, but also realizes truly unattended automatic operation through the integration of intelligent control modules, greatly improving the efficiency and reliability of fire response. At the beginning of the design, the equipment was based on the core concept of “efficient start-up, stable water supply, intelligent control, and durable structure”. It adopts international standard manufacturing processes. The whole machine has undergone strict pressure resistance, flow, head and noise tests to ensure that it still performs well under various extreme working conditions. Its core driving part is a high-performance diesel engine, which uses a low-emission, high-torque, and fast-response power configuration. It can start and deliver water to the predetermined system area in a very short time, and is suitable for various fire hydrant systems, sprinkler systems, foam systems, and fixed fire pipe network systems. Its control system has many intelligent functions, including low oil pressure alarm, abnormal water temperature warning, battery voltage detection, fuel remaining display, cumulative running time recording, etc., to ensure that users can fully grasp the working status during the operation of the equipment. The automatic start-stop function is particularly prominent. When the fire control system starts the signal or the fire pipe network pressure is lower than the set value, the equipment can start automatically; and after the water pressure is restored and stabilized within the set range, the equipment automatically stops, which greatly reduces energy consumption and manual operation risks. In addition, the equipment has a multi-level protection mechanism, including overload protection, overheating protection, overspeed protection, oil shortage and flameout protection, etc. It can monitor its own status in real time during operation, automatically cut off the source of faults, and prevent greater accidents. In terms of pump body structure, it is made of corrosion-resistant cast iron or stainless steel, and is treated with high-strength coating. It can maintain long-term stable operation in harsh environments such as high humidity, high salt fog, and high dust; the coupling part is equipped with an anti-vibration design to effectively absorb fluctuations during power transmission and ensure that the pump body runs more smoothly and quietly. From the perspective of usage scenarios, this diesel engine fire pump is widely used in urban high-rise buildings, underground parking lots, airports, oil depots, chemical parks, power plants, storage centers, logistics parks and other places with extremely high fire protection requirements. Especially in remote areas, without stable city electricity or in field construction environments, this pump group is the preferred solution to ensure continuous water supply and fire fighting even in a power outage. In addition, the equipment also supports the linkage operation mode with the electric fire pump system, and can be used as a backup pump for intelligent switching to form a “double insurance” structure. When the main electric pump cannot be started due to power outage, the diesel pump immediately takes over the hydraulic output automatically to avoid the risk of fire spread. In terms of installation and maintenance, the overall equipment adopts a modular base design, which is easy to transport and install quickly, occupies a small area, and has an intuitive and clear operation interface; users can use the intelligent control panel to start and stop, view parameters, reset faults and trace back historical operation records with one button, which greatly reduces the operation threshold and improves management efficiency. The maintenance cycle is extended to more than 300 hours, and the process of replacing lubricating oil and filter elements is simple. Users can perform periodic maintenance according to the prompt information to avoid hidden dangers caused by inadequate maintenance. In terms of environmental protection, the diesel fire pump group uses environmentally friendly low-sulfur diesel as fuel, and is equipped with a noise reduction exhaust system and an efficient exhaust gas purification device to effectively control noise pollution and emission concentration, in line with the current environmental protection policy requirements of various regions. In terms of energy saving, the equipment adopts high-pressure common rail fuel injection technology to achieve maximum fuel utilization while ensuring strong power and reducing overall operating costs. In order to meet the diverse needs of users, the equipment supports customization of multiple models, with a flow range from 20L/s to more than 100L/s, and a head range of 30 meters to 150 meters. Non-standard selection and configuration can be performed according to the actual working parameters of different projects. At the same time, the remote monitoring module can also be expanded to achieve linkage management with the building automation system or cloud platform, which is convenient for remote viewing of operating status and fault alarm, and realizes the informatization and intelligence of equipment management. In general, this diesel engine fire pump device with automatic start-stop control function not only has the high reliability and strong adaptability of traditional diesel power equipment, but also integrates modern control technology and intelligent sensing functions to achieve a perfect combination of efficient water supply and intelligent management. It is an indispensable key component in the current construction of industrial, civil and special fire protection systems. Its outstanding performance, excellent safety design, intelligent control method and high adaptability make it continue to be favored by users in various large-scale fire protection engineering projects, providing strong technical support for improving the overall fire protection capabilities of cities and facilities.