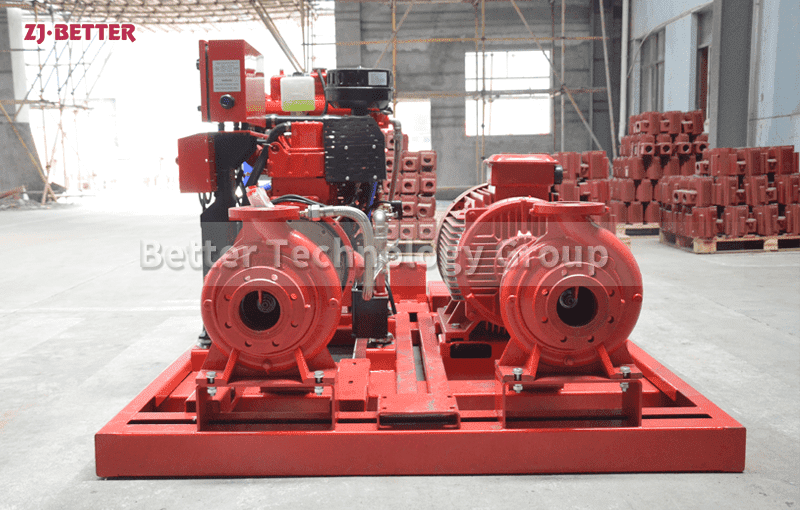

Fire pump set is suitable for various emergency fire fighting occasions

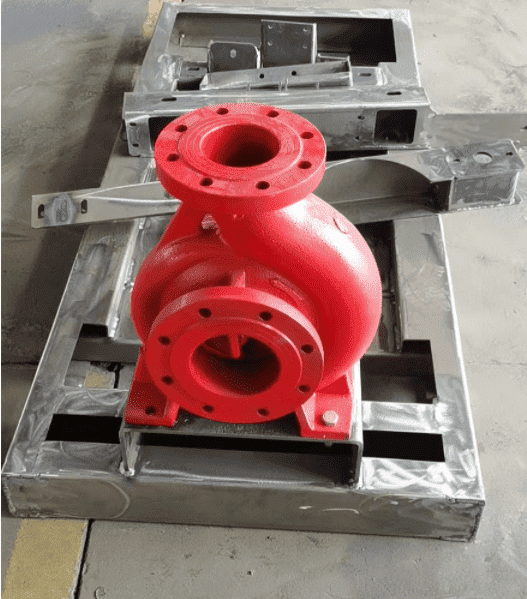

Zhejiang Better Technology Group Co., Ltd. mainly produces various industrial pumps, electric motor fire pumps, diesel engine fire pumps, fire-fighting special water supply equipment, fire-fighting dual-power water supply equipment, general-purpose fire-fighting gas top pressure water supply equipment, fire pump control cabinets, fire-fighting frequency conversion automatic Inspection cabinets, fire protection dual power supply cabinets, submersible sewage pumps, pipeline pumps, chemical pumps, oil pumps, slurry pumps, vacuum pumps and complete sets of vacuum equipment, non-negative pressure water supply equipment, frequency conversion constant pressure water supply equipment and water tanks of various materials, fire protection, Domestic pump room control cabinets, etc., products are widely used in agriculture, machinery, chemical industry, papermaking, medicine, food, sugar, electronics, metallurgy, ceramics, water diversion, printing and dyeing, building materials and other fields.

Installation place: Fire pumps are required to be installed in the temporary high-pressure fire water supply system and the stable high-pressure fire water supply system. In the series fire water supply system and the gravity fire water supply system, in addition to the fire pump, a fire transfer pump is also required. The fire hydrant water supply system and the automatic sprinkler system should be equipped with fire pumps respectively. In addition, it should be noted that the fire water pump should be equipped with a backup pump, and its performance should be consistent with that of the working pump.