Fire System Upgrade Recommendation: High-Performance Centrifugal Pump Enhancing Water Supply Capability

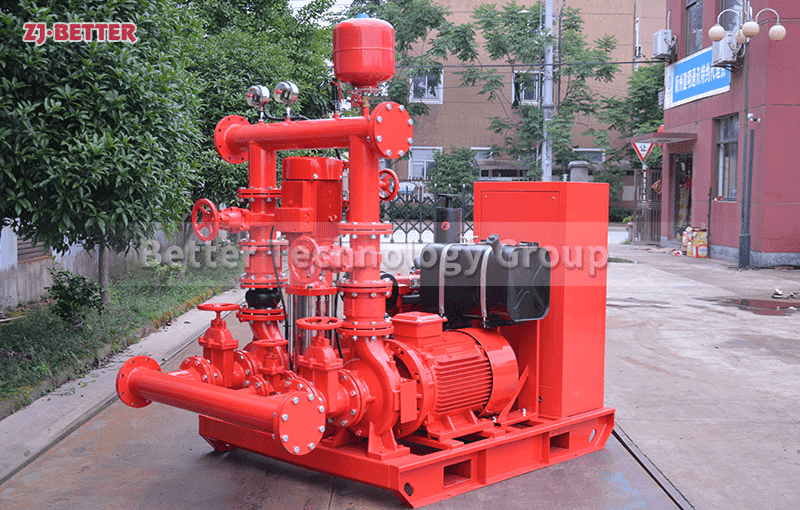

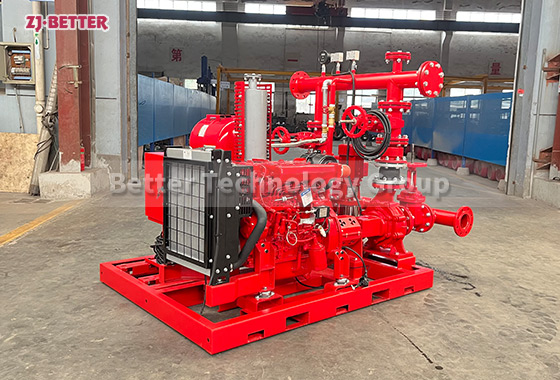

This high-efficiency and durable fire pump features stable pressure output, energy-saving operation, high corrosion resistance, and long-term reliability. It is suitable for fire protection systems in industries, buildings, warehouses, and facilities, ensuring rapid water supply and continuous fire extinguishing capabilities during fire emergencies. It is an ideal fire protection equipment choice that offers safety, stable performance, and low maintenance costs.

Recommended Upgrade for Fire Protection Systems: High-Performance Centrifugal Pumps Enhance Water Supply Capacity. This theme focuses on the higher expectations of modern buildings, industrial facilities, and public protection systems for reliable water supply equipment. High-performance centrifugal pumps, as an indispensable core component of fire protection systems, play a crucial role in various fire protection projects due to their scientific structure, stable operation, high efficiency, rapid response, and wide adaptability. Their design philosophy revolves around energy saving, high-pressure output, rapid start-up, and long service life, providing stronger power performance to support the continuous operation of sprinkler systems, fire hydrant systems, and foam extinguishing systems. They play a key role in the overall upgrade of fire protection systems. This type of pump, employing an end-suction structure, precise impeller balancing design, and precision coupling machining, ensures stable, pulsation-free water output. Even in high-rise buildings, long-distance water delivery, or multi-point water use conditions, it can maintain a continuous supply of high head pressure and sufficient flow. Simultaneously, its efficient hydraulic model structure significantly reduces energy consumption, helping fire protection systems save on electricity costs during long-term operation and bringing continuous economic benefits to project owners and facility operators. High-performance centrifugal pumps particularly emphasize reliability and durability; their pump body is made of wear-resistant high-grade casting materials, and the internal fluid flow transition area is optimized to reduce the risk of erosion and wear. The shaft sealing system utilizes advanced… The sealing design ensures long-term leak-free operation, improving the overall stability and maintenance cycle of the pump. The pump’s motor features a high-quality protection rating and an efficient heat dissipation structure, ensuring safe operation even under long-term high operating loads. It supports frequent starts and can quickly enter working condition during fire emergencies. Its control system is compatible with automatic, manual, and remote start/stop modes, meeting the intelligent needs of different fire control centers and building systems. It also features differential pressure monitoring, operational detection, and alarm signal output functions, enabling system linkage and automatic response control. This high-performance centrifugal pump also demonstrates excellent adaptability in fire protection system design. This equipment can be stably applied in factories, warehouses, buildings, high-rise complexes, hospitals, airports, data centers, and petrochemical and power facilities. It is suitable for combination with sprinkler pumps, pressure-stabilizing pumps, diesel pumps, foam pumps, etc., to achieve multi-pump system operation, better optimizing water source allocation capabilities and improving safety redundancy performance. The installation mode of this equipment is flexible; it can be configured as a base-mounted complete unit or combined with control cabinets and other equipment to form a unit package for rapid deployment. For projects requiring system upgrades, replacement of old pumps, or new construction, it greatly shortens the construction cycle and reduces commissioning workload. Its compact structure and small footprint facilitate optimized design of fire pump room space. Its low operating and maintenance costs, easily accessible routine maintenance points, and infrequent maintenance allow users to benefit from lifecycle cost management. More importantly, through optimized flow channels and improved pump efficiency design, high-performance centrifugal pumps can maintain stable head increases, ensuring sufficient pressure even at the top of high-rise buildings. This addresses the previous problem of insufficient sprinkler coverage due to low pressure, effectively guaranteeing the safety of water supply at the end of the fire protection system. These pumps support multiple power sources, including electric motor drive for general scenarios, and also support redundant configurations with diesel-driven units, allowing the protection system to remain operational even in power outages. This is particularly beneficial for large-scale projects, remote facilities, and critical safety engineering projects. Crucially, modern fire protection systems not only prioritize water spraying capacity but also emphasize response speed and continuous reliability. Optimized pumps ensure instantaneous start-up, guaranteeing sufficient pressure output immediately upon receiving a fire signal, allowing the sprinklers to quickly form a fire-extinguishing coverage layer. High-performance centrifugal pumps also exhibit significant vibration resistance and high stability. Their enhanced pump shaft strength and increased bearing capacity prevent overheating and wear even under high-intensity continuous operation, extending equipment lifespan. This is of great significance for fire pumps, which are designed for standby but must be readily available. Users can customize different flow ranges and head ratings according to their fire protection needs, with a wide range of specifications covering everything from residential to commercial applications. The overall configuration from community pump rooms to large-scale industrial fire protection systems achieves a more rational hydraulic matching effect, meeting needs while avoiding waste. During manufacturing, pumps undergo high-precision machining and performance verification using hydraulic testing platforms to ensure that the equipment meets national and international fire protection application standards. The system also supports a pipeline pressure-stabilizing pump linkage scheme, enabling automatic adjustment of pump operating status and pressure detection. Through pressure stabilization control, frequent start-stop of the main pump can be avoided, improving pump life and system stability. With the ongoing trend of fire protection system upgrades, high-performance centrifugal pumps are not only water supply equipment but also the core power source for improving the reliability of the entire emergency system. Efficiency, long lifespan, and low maintenance are driving the transformation of building fire protection systems towards greater intelligence and reliability. Market demand is constantly growing, and high-performance centrifugal pumps, with their superior performance, have become an important configuration choice for fire water system upgrade projects. In the face of increasingly complex fire risks, they ensure that they can output strong and stable water pressure at all times, providing a solid guarantee for life safety, property protection, and building operation. They are irreplaceable key machines in modern fire protection systems. In the future, they will continue to play a greater role in improving fire protection standards, integrating intelligent systems, and meeting energy-saving operation requirements, helping various industries establish safer, more efficient, and more sustainable water supply and protection systems.