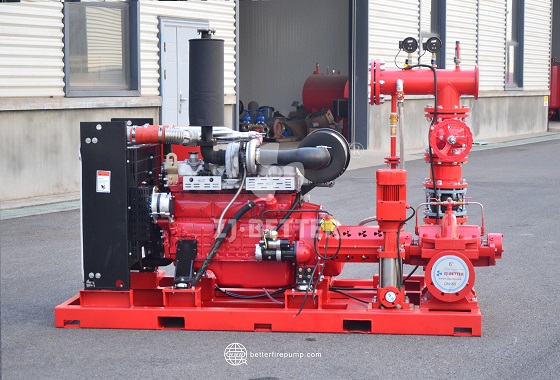

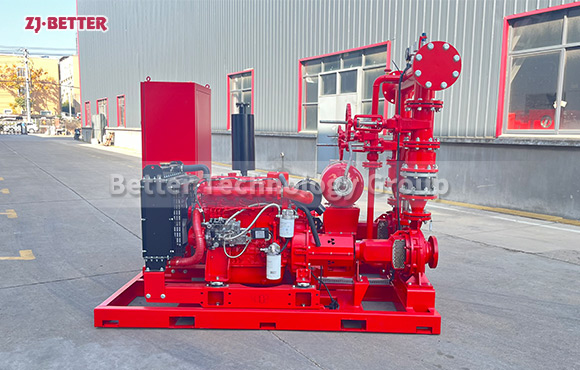

Engine-Powered Fire Pump System for Oil Fields, Warehouses, and Logistics Parks

Explore the advantages of an engine-powered fire pump system designed for oil fields, warehouses, and logistics parks. Delivering high performance, independence from power grids, and compliance with international fire safety standards.

Engine-powered fire pump systems play a vital role in ensuring the safety and fire protection of facilities such as oil fields, warehouses, and logistics parks, where large-scale operations, high-value assets, and complex infrastructure demand reliable and autonomous fire water supply. Unlike electric pump systems that rely entirely on grid power, engine-powered fire pumps operate independently of electrical sources, making them the ideal solution for remote, hazardous, or power-constrained environments. This type of fire pump system is typically driven by a diesel engine, offering robust power output, operational flexibility, and superior reliability even in the most critical conditions. The pump system shown here is a fully integrated solution that includes a horizontal split-case or end-suction centrifugal pump, a diesel engine, a heavy-duty base frame, a control panel, a fuel tank, cooling systems, battery starters, exhaust silencing system, pressure gauges, and essential pipeline components. It is engineered to deliver optimal performance in high-demand firefighting scenarios and is designed to be compliant with international fire protection standards such as NFPA 20. One of the core advantages of this engine-driven fire pump system lies in its self-sufficiency. In oil extraction fields, where power infrastructure may be limited or unstable, the engine-powered design allows it to function as a standalone firefighting unit, initiating pump operation via automatic or manual start in case of emergency. The integrated battery system ensures quick and reliable engine ignition, while the advanced control panel provides real-time monitoring of engine temperature, oil pressure, water pressure, RPM, and battery voltage. It also supports remote start capabilities and signal output functions to connect with centralized control systems. This makes it highly suitable for oil and gas environments that require 24/7 fire readiness. For warehouse complexes and logistics parks, where fire risks are elevated due to high storage density, flammable materials, and constant movement of goods, this pump system ensures rapid response and high-pressure water delivery over extensive piping networks. The high flow rate and pressure capacity of the centrifugal pump can be tailored to meet the specific protection layout, including sprinkler systems, hydrants, and foam systems. The use of durable materials such as cast iron or bronze for pump bodies, stainless steel for shafts and impellers, and heat-treated components ensures longevity and corrosion resistance, which are crucial in industrial and outdoor installations. Moreover, the entire system is skid-mounted, allowing for simple and secure installation on concrete foundations or steel platforms. This modular configuration facilitates transportation and relocation when needed, making it ideal for temporary or evolving projects. The fuel tank is designed for extended operation, typically allowing up to 8-10 hours of continuous running without refueling, and includes fuel level indicators and alarms to prevent dry operation. The cooling system, either air or water-based, is engineered to maintain optimal engine temperature even under prolonged full-load conditions. Additionally, the exhaust system is equipped with a high-efficiency silencer to reduce noise pollution, particularly beneficial in logistics parks operating around the clock. Safety and automation are at the forefront of the system design. Multiple protection mechanisms are built in, such as automatic shutdown on low oil pressure, high engine temperature, or overspeed detection. The pump can be programmed to perform weekly test runs to ensure system readiness, and all data can be recorded and exported for maintenance tracking. These features significantly reduce the risk of pump failure during a real emergency. Customization is another strong point. This engine-powered fire pump system can be configured based on the client’s flow and head requirements, regional climate conditions, available installation space, and connection types. Optional accessories include jockey pumps for pressure maintenance, pressure relief valves, flow meters, test headers, remote alarm modules, and GSM or IoT modules for smart monitoring. The control panel can be provided in local language interfaces and support integration into building management systems (BMS). Furthermore, in regions where emission standards and noise regulations are stringent, the engine can be upgraded to comply with local Tier emission levels and fitted with insulation covers or soundproof canopies. When deployed in hazardous zones such as oil refineries or chemical storage facilities, explosion-proof control panels and ATEX-certified components can be provided to ensure compliance and safety. In terms of performance, the system offers flexible flow ranges typically from 500 to 4000 GPM, and pressure heads from 50 to 180 meters, depending on the selected pump model and engine size. The operating temperature range extends from -20°C to +55°C with proper cold-start systems and ventilation design. Thanks to its engineering-grade construction, this pump system is resistant to vibrations, temperature changes, humidity, and long idle times. It can remain idle for months and still start promptly when called into service, which is essential for passive fire protection systems. Quality control and factory testing are key to its reliability. Each unit is assembled, aligned, and tested in accordance with international standards, including flow rate, pressure, rotation direction, alarm functions, and automatic control performance. All systems are delivered with documentation including test reports, wiring diagrams, user manuals, and installation guides, ensuring seamless commissioning by the client’s team or local contractors. In summary, this engine-powered fire pump system is a highly dependable, configurable, and efficient solution tailored for critical applications in oil fields, warehouses, and logistics parks. Its independence from grid power, high performance under stress, long-term durability, and smart control integration make it a preferred choice for industrial-grade fire protection systems around the world. Whether facing environmental challenges, infrastructure limitations, or strict compliance requirements, this fire pump system delivers peace of mind with every operational cycle.