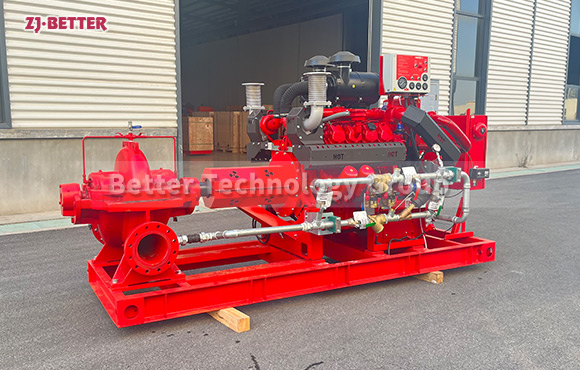

Diesel Fire Pump Engineered for Industrial Sites: High Head, Low Maintenance, Long Service Life

This diesel engine-driven fire pump set is engineered for emergency water supply in critical environments. Featuring powerful performance, fast start-up, and stable operation, it integrates a globally recognized diesel engine and a high-efficiency centrifugal pump for continuous duty. The compact design ensures easy installation and maintenance, while the intelligent control panel supports auto start, fault alarms, and remote monitoring. Built to withstand harsh conditions like high temperature and humidity, this pump set meets international standards such as NFPA 20, making it ideal for petrochemical plants, power stations, storage facilities, and high-rise buildings.

As safety regulations tighten for industrial sites and public infrastructure, the demand for high-performance, fast-response, and stable fire protection solutions has never been greater. ZJ-BETTER’s latest high-efficiency diesel fire pump set combines powerful engine systems, intelligent automation, and top-tier hydraulic design to deliver exceptional reliability in mission-critical environments.

1.Robust Diesel Engine, Guaranteed Start

Powered by renowned engine brands , this pump unit offers high torque, low fuel consumption, and dependable cold starts even under extreme temperatures. Perfect for emergency readiness.

2.Hydraulically Optimized Pump, Superior Flow and Head

Fitted with a high-efficiency single or multi-stage centrifugal pump, the unit delivers strong discharge pressure and high flow rate. Built with stainless steel or cast iron for excellent corrosion resistance and extended pump life.

3.Smart Control System, Seamless Operation

Equipped with a PLC-based intelligent control panel, featuring touchscreen interface, auto-start, real-time diagnostics, remote monitoring, fault alarms.

4.Modular Integration, Easy Installation and Maintenance

Compact design with skid-mounted base and integrated layout, greatly reducing on-site setup time. Ideal for tight machine rooms or underground installations. Simplifies inspection and long-term servicing.

5.Adaptability to Harsh Environments

Fully independent from the grid, this diesel unit excels in remote or disaster-prone areas. With built-in fuel tank and air or water cooling options, it runs continuously for over 4–8 hours—ideal for mines, offshore platforms, or areas with unreliable power.

6.Certified to Global Fire Standards

Conforms to NFPA20 and other relevant standards. Manufactured under ISO9001 quality systems and China’s CCCF fire safety certification, ensuring quality, traceability, and compliance for major engineering projects.

Typical Applications:

Petrochemical plants & gas stations

Data centers & high-rise buildings

Ports, tunnels & subways

Power plants, ships & logistics parks

Choosing ZJ-BETTER means choosing:

Certified safety

Continuous performance

Long-lasting durability

Energy-efficient power

Smart fire protection