The Max Power-2000kw-10KV Split Case EDJ Fire Pump Set: Unleashing Firefighting Potential

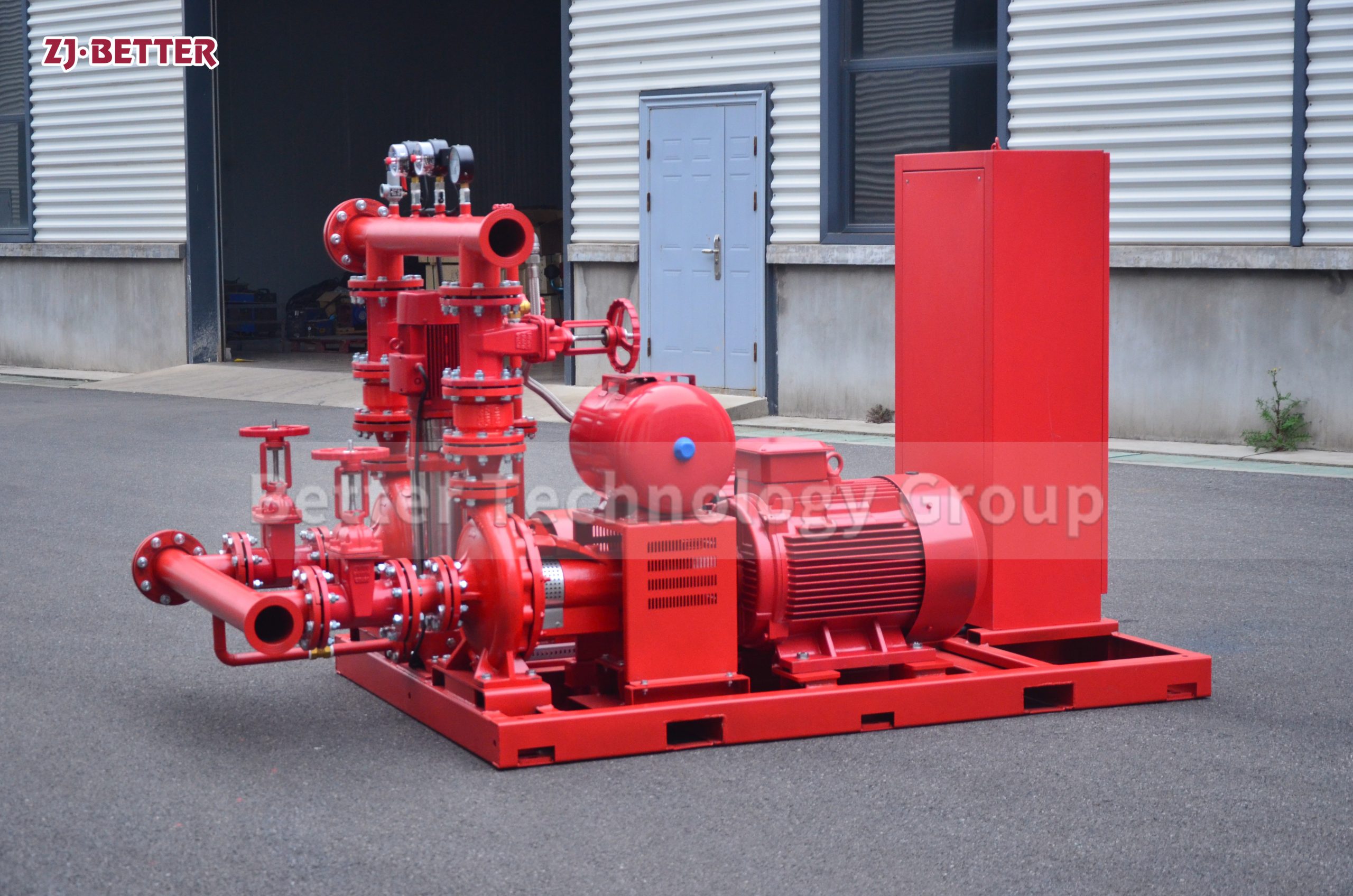

The Max Power-2000kw-10KV Split Case EDJ Fire Pump Set is a cutting-edge fire protection solution that combines power, efficiency, and reliability. With a remarkable power output of 2000 kilowatts and a 10-kilovolt system, this fire pump set delivers unmatched water flow capacity and electrical performance. Its advanced Split Case design ensures easy maintenance and optimal performance, making it suitable for a variety of applications. Engineered to exceed industry standards, the Max Power-2000kw-10KV Split Case EDJ Fire Pump Set offers dependable fire protection in the most demanding environments. Invest in this state-of-the-art solution and experience the pinnacle of fire safety technology.

This state-of-the-art fire pump set combines power, efficiency, and reliability to provide unmatched performance in safeguarding lives and properties from the devastating effects of fire.

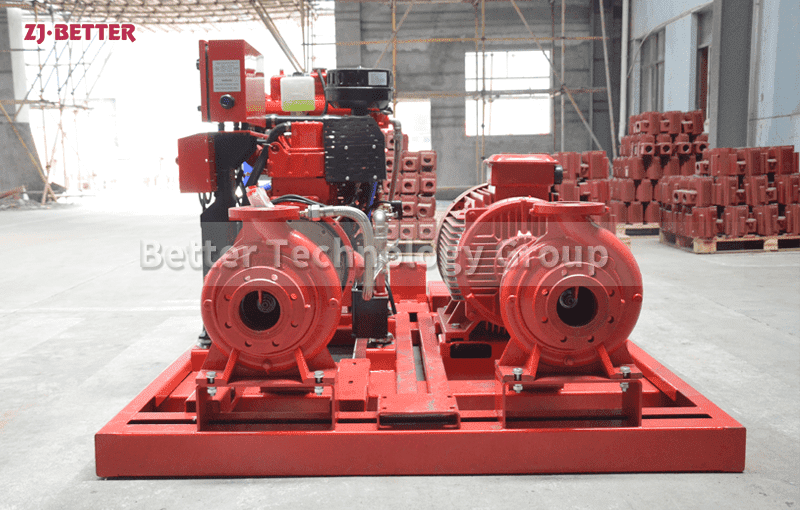

(1)Unleash Unmatched Power:

With a staggering power output of 2000 kilowatts, the Max Power-2000kw-10KV Split Case EDJ Fire Pump Set delivers an impressive water flow capacity, ensuring rapid fire suppression capabilities. It is designed to combat even the most demanding fire scenarios with exceptional force and effectiveness.

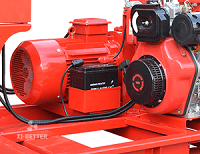

(2)Advanced Split Case Design:

The Split Case design of the fire pump enhances its efficiency and reliability. The innovative design allows for easy maintenance and servicing, ensuring optimal performance and prolonged lifespan. Its robust construction and high-quality components guarantee uninterrupted operation when it matters the most.

(3)High Voltage Capability:

Equipped with a 10-kilovolt (10KV) system, the Max Power-2000kw-10KV Split Case EDJ Fire Pump Set provides superior electrical performance, allowing for efficient power transmission and operation. It is designed to meet the demanding requirements of modern fire protection systems, providing a reliable and stable power supply.

(4)Versatile Application:

The versatility of the Max Power-2000kw-10KV Split Case EDJ Fire Pump Set makes it suitable for a wide range of applications. Whether it’s protecting large industrial complexes, high-rise buildings, or critical infrastructure, this fire pump set excels in delivering comprehensive fire safety coverage.

(5)Dependable Fire Protection:

When it comes to fire safety, reliability is paramount. The Max Power-2000kw-10KV Split Case EDJ Fire Pump Set is engineered to meet and exceed the highest industry standards, ensuring dependable fire protection in the most demanding environments. Trust in its robust performance and rest easy knowing that your fire protection needs are in capable hands.