High-Pressure Constant Flow Fire Pump System: Reliable Water Supply When It Matters Most

High-pressure steady-flow fire pump systems offer advantages such as efficient water supply, stable pressure, and intelligent control, ensuring rapid startup and continuous water supply during fire emergencies. The equipment utilizes pressure-resistant and corrosion-resistant materials, variable frequency energy-saving technology, and a fully automatic control system, making it suitable for high-rise buildings, industrial facilities, power stations, and other locations, providing a safe and reliable high-pressure water source for fire protection systems.

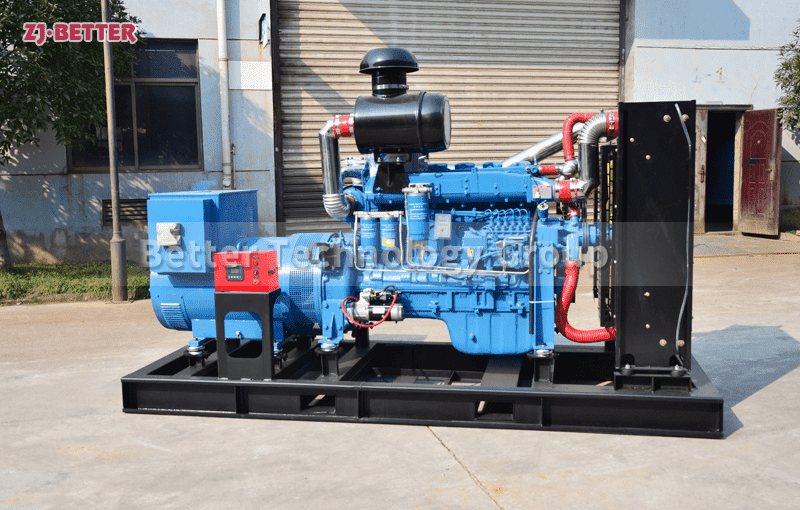

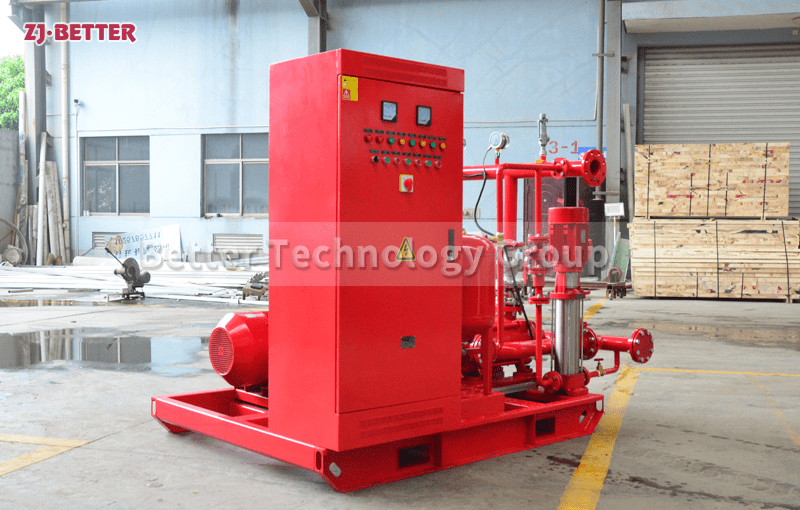

High-pressure steady-flow fire pump systems are highly efficient water supply devices specifically designed for buildings, industrial facilities, warehousing bases, power stations, and various fire protection sites. Through advanced hydraulic design and intelligent control technology, they ensure rapid startup and a continuous, stable high-pressure water flow in any fire emergency, providing powerful and reliable water support for the entire fire protection system. With the continuous expansion of modern building scale and increasingly stringent fire protection standards, the requirements for the performance and reliability of fire pumps are becoming more stringent. High-pressure steady-flow fire pump systems are representative products that meet this trend. They not only possess strong water supply capacity but also offer multiple advantages such as energy saving, automation, and high safety, making them an indispensable key device in modern fire protection engineering. The design concept of this pump system is based on “high efficiency, safety, and stability.” Its high-pressure output performance ensures that the water flow maintains sufficient pressure and flow during long-distance transportation, achieving rapid water supply and precise pressure control in multi-story buildings, underground facilities, and remote sprinkler systems. The system typically consists of a high-pressure main pump, a pressure-stabilizing pump, a control cabinet, a pressure-stabilizing tank, and various sensors. These components work in precise coordination through an intelligent control unit, automatically detecting pressure changes and adjusting output power in real time to ensure stable water pressure. One of the biggest performance advantages of the high-pressure steady-flow fire pump system is its excellent start-up response speed. When the fire alarm system is triggered, the main pump can start in a very short time, instantly filling the pipe network with water and minimizing fire response delays. Simultaneously, the pressure-stabilizing pump within the system continuously maintains the static pressure of the pipe network in non-fire alarm states, ensuring the entire fire pipeline is always ready to start. This design not only saves energy but also effectively extends the service life of the main pump, avoiding mechanical wear caused by frequent start-ups and shutdowns. Another significant advantage of the system is its powerful high-pressure water supply capacity. The high-pressure steady-flow fire pump system can output extremely high working pressures, meeting the needs of high-rise buildings, long-distance water delivery, or high-flow sprinkler systems. Its pump body is made of high-strength cast iron or stainless steel, offering excellent pressure resistance. Combined with a high-efficiency impeller design, it minimizes hydraulic losses and maximizes efficiency. Even in harsh operating environments, such as high temperature, high humidity, or water containing microparticles, the system maintains stable operation. Thanks to its precision shaft seal structure and anti-corrosion coating, the entire unit possesses excellent corrosion resistance and leak-proof performance, significantly reducing maintenance frequency and operating costs. In terms of energy saving, the high-pressure steady-flow fire pump system employs advanced variable frequency control technology, automatically adjusting the motor speed according to the actual pressure requirements of the system, ensuring the pump unit maintains optimal operating conditions under different loads. This intelligent variable frequency control not only reduces energy consumption but also reduces equipment vibration and noise, making the system operate more smoothly and quietly. Compared to traditional fixed-speed pump sets, this system improves energy efficiency by more than 20%, and significantly reduces electricity costs over long-term use, meeting the requirements of modern fire-fighting equipment development towards green and energy-saving directions. Reliability is one of the most important performance indicators of the high-pressure steady-flow fire pump system. The system adopts a fully automatic control design and can be linked with various fire-fighting equipment such as fire alarm systems, sprinkler systems, and wet alarm valves to achieve unattended operation. When the pressure sensor detects a drop in pipeline pressure to the set lower limit, the pressure-stabilizing pump automatically starts to replenish the pressure. If the pressure continues to drop or a fire alarm signal is detected, the main pump immediately takes over the water supply operation, requiring no manual intervention throughout the process. The system is also equipped with multiple protection functions, including overload protection, phase loss protection, over-temperature alarm, and anti-dry-running safety mechanisms, ensuring safe and stable operation under various emergencies. The high-pressure steady-flow fire pump system emphasizes modularity and compactness in its structural design, making installation and maintenance extremely convenient. All components are designed and manufactured according to international fire protection standards and can be flexibly combined with different types of electric motor or diesel engine drives to adapt to the energy conditions of different application scenarios. The system base adopts an integral welded structure, possessing high strength and seismic resistance, ensuring stable operation even in earthquakes or impact environments. Furthermore, the system’s reasonable pipeline layout and standardized interfaces make installation quick and easy, allowing direct connection to existing fire pipeline networks without complex modifications, greatly improving construction efficiency. In terms of durability, all key components of the high-pressure steady-flow fire pump system have undergone rigorous quality testing and durability trials. The pump body is precision-machined and specially treated for rust prevention, effectively resisting scale buildup and corrosion. The motor employs a high-efficiency cooling system and a waterproof sealing structure, enabling long-term stable operation in high-temperature or high-humidity environments. The bearings utilize imported high-precision components, ensuring ample lubrication and superior wear resistance, guaranteeing long-term operational stability. The system’s average service life exceeds ten years, with minimal maintenance required during this period; only basic daily checks and cleaning are needed to maintain optimal performance. In terms of application, the high-pressure steady-flow fire pump system covers almost all locations requiring fire protection. It is widely used in large commercial complexes, underground parking lots, petrochemical bases, power plants, airports, ports, tunnels, and residential areas. For systems with high water pressure requirements or long supply distances, this equipment leverages its high pressure and high flow rate advantages to ensure simultaneous water supply for multiple devices such as sprinklers, fire hydrants, and foam extinguishing systems. In areas with unstable power supply, the system can be equipped with a diesel engine drive unit for independent operation, ensuring a sufficient water supply even during power outages. Beyond its superior performance, the high-pressure steady-flow fire pump system also leads the industry in intelligent management. Its control system is equipped with a programmable logic controller (PLC) and a human-machine interface (HMI). Operators can monitor key operating parameters such as pressure, flow rate, current, and temperature in real time via a touchscreen. The system also supports remote monitoring and automatic alarm functions, and can upload operating status data to the control center via a network interface for remote diagnosis and maintenance. This intelligent design significantly improves the system’s management efficiency and safety level, making it more in line with the needs of modern smart fire protection. In summary, the high-pressure steady-flow fire pump system, with its advantages of high efficiency and energy saving, stable operation, high degree of automation, and safety and reliability, has become a crucial core device in modern fire water supply systems. Whether from the perspective of structural design, operational performance, or intelligent control, it embodies the advanced level of fire equipment technology. With the continuous improvement of fire safety regulations and the increasing requirements for building fire protection, the high-pressure steady-flow fire pump system will be widely used in more engineering projects, providing stronger technical support for urban safety and the protection of life and property. It is not just a piece of equipment, but a key force in modern fire protection systems to ensure “uninterrupted water supply and no pressure drop,” truly fulfilling the promise of providing reliable water supply in critical moments.