In-Depth Overview of Energy-Efficient Electric Fire Pump Sets

Explore the high-efficiency and energy-saving advantages of electric fire pump sets. Designed for stable performance, intelligent control, and low maintenance, this firefighting solution is ideal for modern buildings and critical fire protection systems.

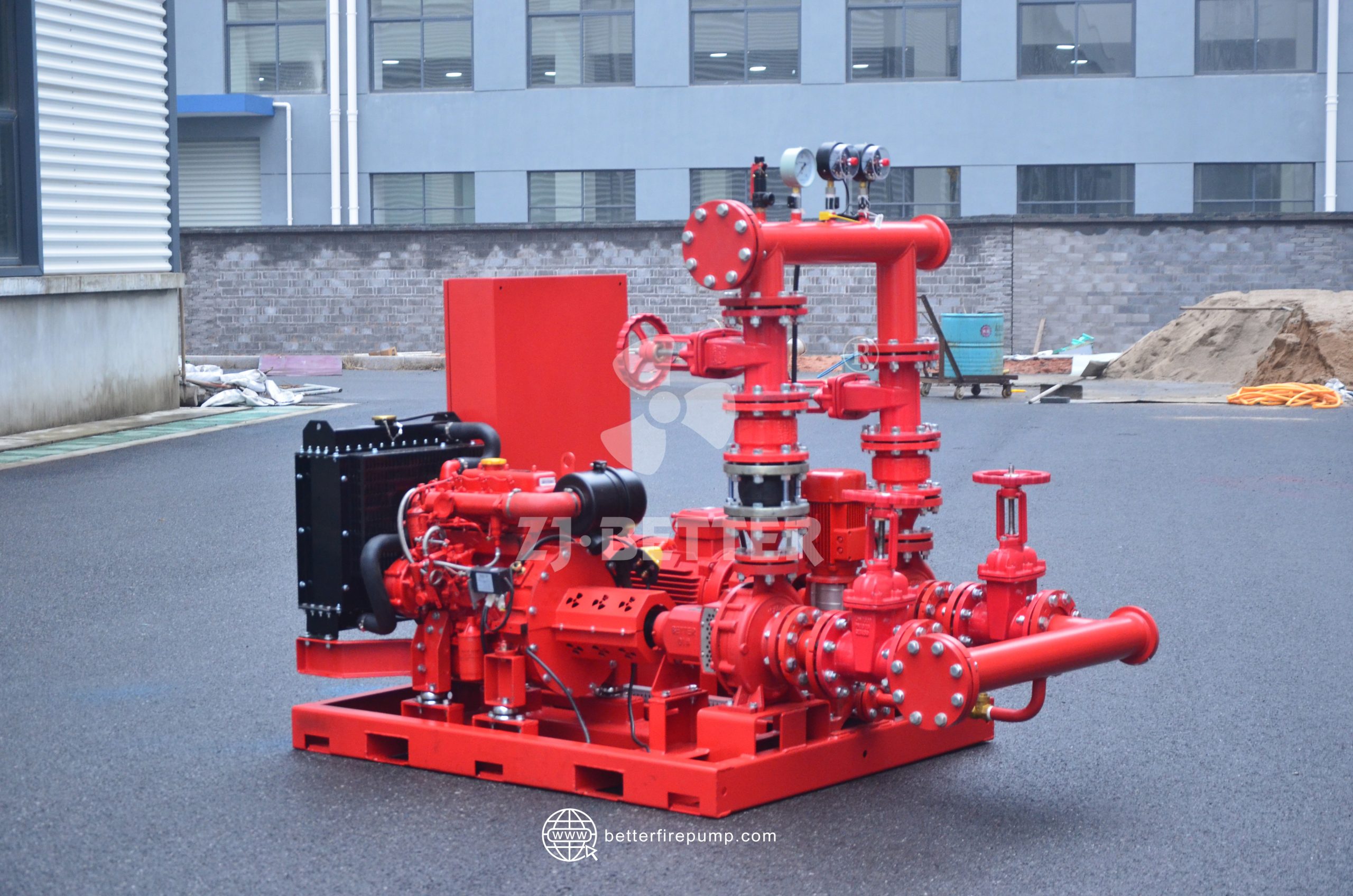

In modern building fire protection systems, electric fire pumps, as core water supply equipment, play a vital role. They not only determine the speed of firefighting response in the early stages of a fire but also directly impact the stability and reliability of the entire fire protection system. Compared to traditional diesel-powered equipment, electric fire pumps, with their significant advantages such as high efficiency, low noise, intelligent operation, and easy maintenance, are increasingly being used in various locations, including industrial parks, commercial buildings, residential communities, and warehouses and logistics bases. Energy conservation is a prominent advantage of electric fire pumps. They utilize an advanced motor drive system with high energy conversion efficiency and intelligently adjust their operating state based on varying system pressure and flow requirements, significantly reducing energy consumption and improving overall system efficiency. During routine maintenance and testing, electric pumps can also enter a low-power standby mode, reducing annual energy consumption by over 30% compared to traditional equipment, truly achieving the goal of energy conservation and emission reduction. Stable performance is another key advantage. With fast startup response, smooth operation, and low noise levels, electric fire pumps are particularly suitable for indoor locations where noise control is crucial. Their startup time is typically controlled within 5 seconds, and they feature automatic detection capabilities. If voltage anomalies, overloads, or undervoltage conditions occur, they automatically trigger protection and alarms, minimizing system operational risks. Furthermore, the high-quality bearing design and pump body materials ensure long-term continuous operation without overheating, enhancing reliability. Intelligent control features significantly enhance operational convenience and system integration. Modern electric fire pump sets are often equipped with intelligent control panels featuring LCD displays, fault self-diagnosis, automatic inspections, remote start and stop, and real-time data upload. Users can monitor system status at any time via networked devices, reducing manual management costs. Furthermore, these systems can be linked to the building’s central fire control system for automatic start and stop control, ensuring rapid pump intervention in the event of a fire, significantly improving firefighting efficiency. Electric fire pump sets typically utilize high-strength cast iron or stainless steel for their pump bodies, offering corrosion resistance and high-pressure resistance. They are suitable for a variety of water sources, including tap water, pond water, and recycled water. Their sealing structure often utilizes mechanical seals or multi-layer leak-proofing, effectively preventing leakage even under high-temperature and high-pressure conditions, thereby ensuring long-term, efficient operation. Compact construction and flexible installation are also major advantages of electric fire pump sets. These pump sets often feature an integrated base structure, occupying a small footprint and making them suitable for installations with limited machine room space. Some models support both vertical and horizontal installation, and the pipe interface orientation can be customized to suit various project pipeline layouts, resulting in a short installation cycle and high construction efficiency. Compared to diesel-powered units, electric fire pump sets are simpler to maintain, eliminating the need for frequent oil changes and cooling system inspections. Routine maintenance primarily involves checking electrical wiring and cleaning the pump body, saving time and effort, reducing failure rates, and significantly lowering operating and maintenance costs. Over long-term use, electric pump sets demonstrate superior stability and cost-effectiveness, making them particularly suitable for applications with high operating frequencies or stable power supplies. Regarding noise control, electric fire pump sets operate virtually silently, with overall operating noise levels far lower than those of diesel-powered units, meeting the environmental and comfort requirements of most urban construction projects. Especially in commercial office buildings, hotels, and hospitals, quiet operation is a crucial consideration for users. Furthermore, some high-end electric fire pump units are equipped with silencers and shock-absorbing mounts, further enhancing their quiet operation. Safety is also a key consideration. Modern electric fire pump units are certified to multiple safety standards and feature electrical insulation, short-circuit, and overcurrent protection, effectively preventing system damage caused by electrical failures. Furthermore, some models support dual power switching, automatically switching to a backup power source in the event of a primary power failure, ensuring continuous water supply during critical moments. Furthermore, some units can be combined with diesel pumps or pressure-stabilizing pump units to create a multi-level water supply system, enhancing the redundancy and risk resilience of the overall fire protection system. In terms of applicability, electric fire pump units offer a variety of models and configurations, tailored to different application scenarios. These include horizontal single-stage, vertical multi-stage, variable frequency constant pressure, and dual-pump combinations, flexibly adapting to diverse system requirements, such as sprinkler systems, fire hydrant systems, and water curtain systems. Some high-pressure models meet the high lift and high flow requirements of super-high-rise buildings, with maximum discharge heads exceeding 200 meters and discharge flows reaching thousands of cubic meters per hour, meeting the diverse needs of complex projects. Regarding durability, electric fire pump sets undergo rigorous production control at every stage, utilizing advanced CNC machining technology and a multi-layer anti-corrosion coating, ensuring stable operation for years in challenging environments such as humidity, heat, corrosion, and dust. Some models offer a design lifespan exceeding 15 years, reducing equipment replacement frequency and saving long-term investment costs. For project managers, this is a reliable option with a high return on investment. Finally, electric fire pump sets, due to their environmentally friendly, stable operation, and mature technology, are gradually replacing traditional powered pumps and becoming a staple in modern building fire protection systems. They not only embody current energy-saving and environmentally friendly design concepts but also align with the development trends of smart buildings and intelligent fire protection, making them an indispensable component of modern fire protection projects. Whether for new construction or renovation, choosing a high-performance electric fire pump set is a wise choice for improving safety, optimizing system efficiency, and reducing operation and maintenance costs. With the continuous advancement of technology, the intelligence, modularization and multi-functionality of electric fire pump units will be further enhanced, providing safer, more stable and efficient fire water supply solutions for various projects.