How to Ensure Your Fire Pump Meets NFPA 20 Standards

Ensure your fire pump meets NFPA 20 standards with this guide. Learn about installation, testing, and performance requirements.

The NFPA 20 standard outlines requirements for fire pump selection, installation, and maintenance to ensure the effective operation of fire protection systems.

How to Ensure Compliance:

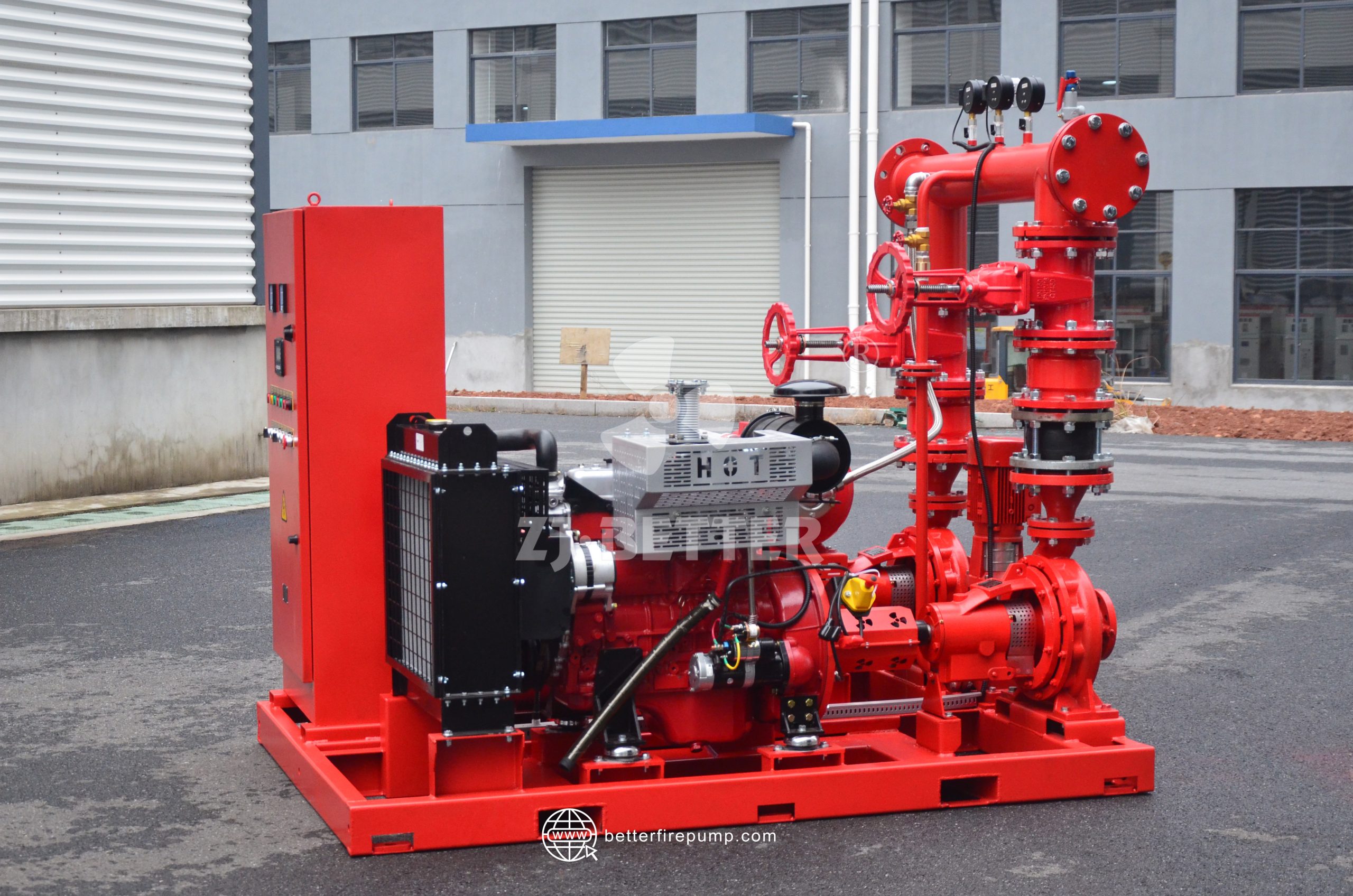

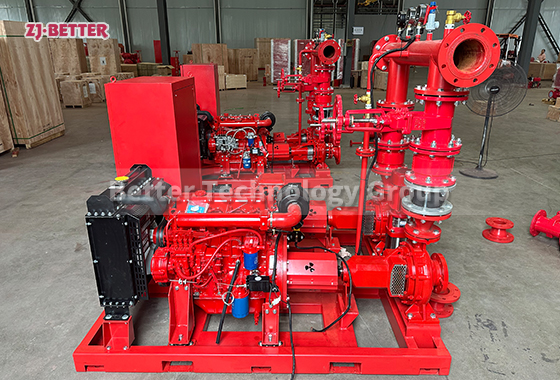

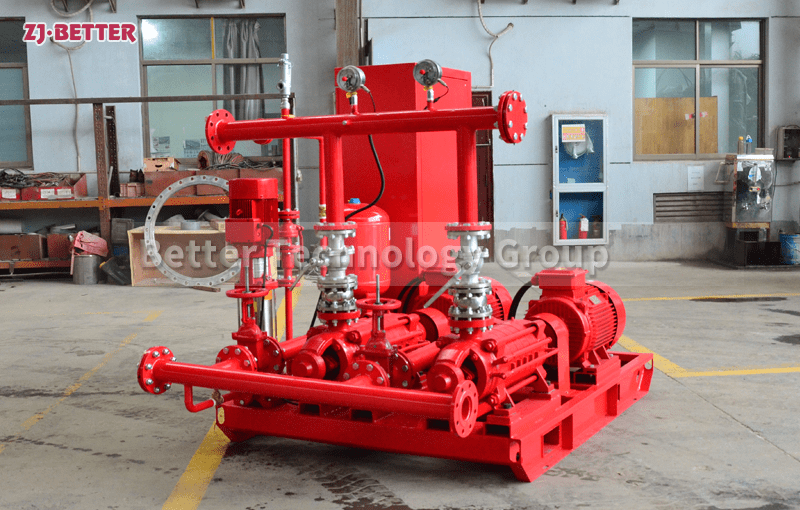

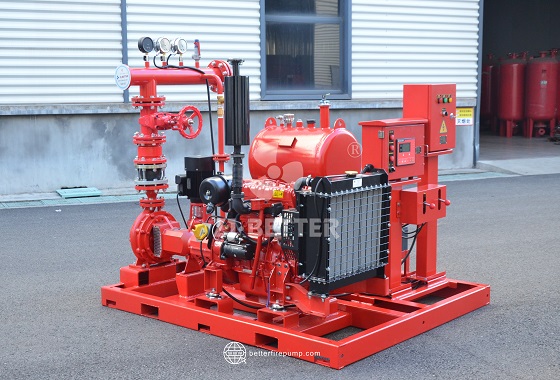

- Pump Type & Capacity – Choose UL/FM-approved fire pumps that match your building’s fire suppression needs.

- Installation Requirements – Follow proper placement, clearance, and ventilation guidelines.

- Regular Testing & Maintenance – Perform weekly, monthly, and annual pump tests.

- Performance Monitoring – Ensure the fire pump delivers the correct flow rate and pressure.

Non-compliance can result in system failure during emergencies. Regular inspections and professional servicing are essential.

3. How to Size a Fire Pump Correctly for Maximum Efficiency

SEO Title: Fire Pump Sizing Guide: How to Select the Right Capacity for Efficiency

Meta Description: Learn how to size a fire pump correctly to maximize efficiency and ensure compliance with NFPA 20 requirements.

Blog Post:

Proper fire pump sizing ensures adequate water supply for fire suppression while avoiding excessive energy consumption.

Steps to Size a Fire Pump Correctly:

- Determine Water Demand – Calculate the required GPM based on building type and fire hazard classification.

- Assess System Pressure – Ensure the fire pump can meet minimum PSI requirements.

- Consider Friction Losses – Account for losses in piping and fittings.

- Check NFPA 20 Guidelines – Verify that the selected pump meets regulatory standards.

Incorrect sizing can lead to system failure or inefficiencies. Work with a certified fire pump manufacturer to get accurate recommendations.