Diesel engine fire pumps meet national standards

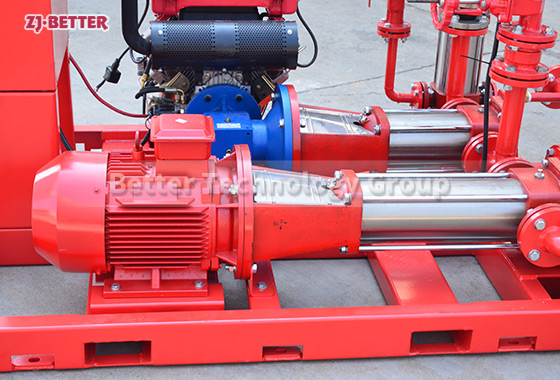

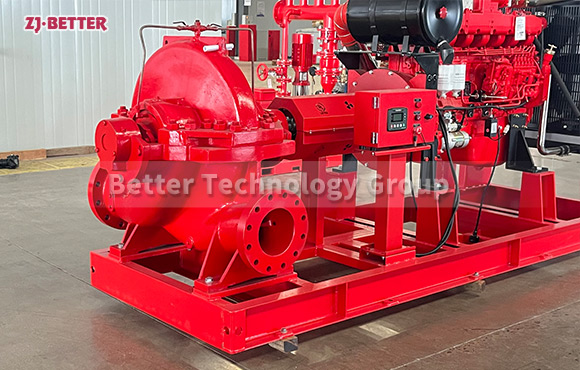

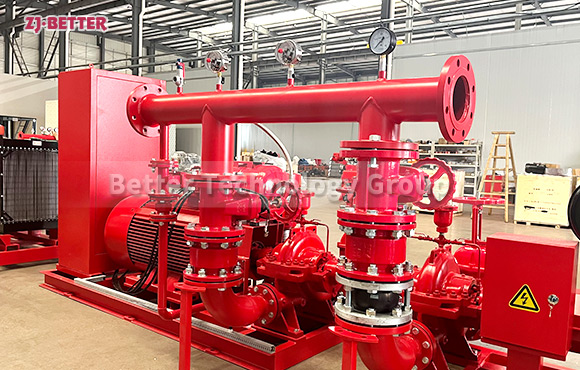

Diesel engine fire pumps are fire-fighting equipment produced by our company for many years to meet the actual needs of users and the requirements of modern fire-fighting technology. Manufactured with mature control technology and reliable components. The system has the advantages of high technical content, high degree of automation, and perfect performance, all of which meet the relevant requirements of national standards.

1. It has a complete indication system: ready to start, manual start, automatic start, unit running, unit shutdown, battery charging, overspeed, diesel engine lubricating oil pressure is too low, supercharger oil pressure is too low, diesel engine lubricating oil oil temperature is too high Low. Diesel engine cooling water temperature is too high. Battery voltage is too low. Fuel oil level is too low (or missing). Diesel engine cooling water temperature is too low. Preheating. Regular inspection.

2. It has a perfect alarm or protection system: alarm or protection for three startup failures, overspeed alarm or protection, low lubricating oil pressure alarm or protection, low supercharger oil pressure alarm or protection, high cooling water temperature alarm or protection Protection. Lubricating oil temperature is too low alarm or protection. Automatic charging device failure alarm. Battery voltage is too low alarm. Battery voltage is too high alarm. Oil level low alarm or protection.

3. It has a perfect display system: diesel engine lubricating oil pressure, diesel engine speed, battery charging current, battery charging voltage.