A New Generation of Energy-Efficient Power Systems: Performance Analysis of Diesel Fire Pumps

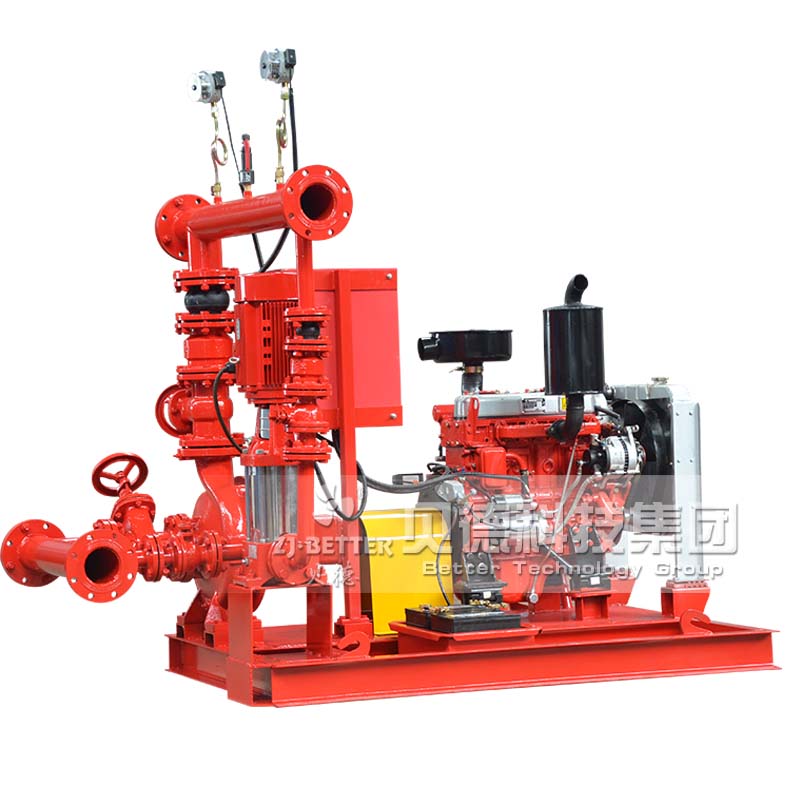

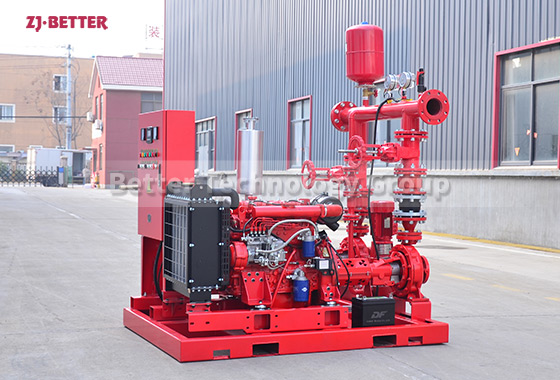

This new generation of diesel fire pumps offers powerful power, independent operation, and high energy efficiency. Utilizing advanced fuel systems and intelligent control technology, they provide reliable water supply even during power outages or in harsh environments. Their high head, high flow rate, and low energy consumption are widely used in high-rise buildings, industrial plants, oil depots, power plants, and ports, making them an ideal solution for ensuring reliable fire protection system operation and secure emergency water supply.

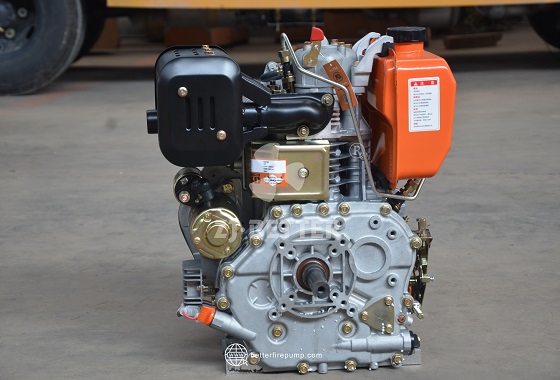

As an indispensable core component of modern firefighting systems, diesel fire pumps, with their powerful power output, independent operation capabilities, and exceptional reliability, demonstrate exceptional performance in a variety of complex scenarios, including fire response, water supply, and industrial emergencies. They are not only essential for fire safety, but also a reliable source of power for stable water supply in critical moments. The new generation of diesel fire pump systems has been comprehensively optimized for energy efficiency and high efficiency, integrating advanced fuel technology, intelligent control systems, and high-precision fluid dynamics design to achieve a perfect balance between performance and energy efficiency. The core advantage of diesel fire pumps lies primarily in their independent power supply. Unlike electric fire pumps, diesel engine-driven pump units do not rely on an external power supply. Even in the event of a fire-induced power outage, they can start quickly and operate stably, ensuring continuous water supply in emergencies. This feature makes them the preferred equipment for emergency water supply in critical locations such as hospitals, high-rise buildings, oil depots, storage bases, power plants, and ports. The diesel engine’s high-pressure common rail injection system enables precise fuel control, ensuring more complete combustion and smoother power output, while also reducing fuel consumption and emissions. The diesel engine maintains excellent starting performance and operational stability in harsh environments, including high and low temperatures and at high altitudes. Secondly, the diesel fire pump’s structural design prioritizes efficiency and reliability. The unit utilizes a modular design, integrating the pump body, base, diesel engine, coupling, and control system onto a single base, resulting in a compact structure and easy installation. The high-strength cast iron pump body offers excellent corrosion and high-pressure resistance, adapting to the pressure requirements of various fire protection pipe networks. The hydraulic components have been optimized through fluid simulation, and the matching impeller and volute design improves hydraulic efficiency, resulting in higher flow rates, higher head, and lower energy consumption. Furthermore, high-precision mechanical seals ensure long-term leak-proof operation, significantly extending the equipment’s service life. The diesel fire pump system also demonstrates advanced control and automation. Its intelligent control cabinet houses a built-in microprocessor control system, enabling automatic start-up, automatic switching, pressure detection, fault alarms, and fuel monitoring. The system automatically determines start-up conditions based on changes in fire protection pipe network pressure. It automatically starts the diesel engine to supply water when pressure drops to a set value and automatically shuts down and remains on standby when pressure returns. The control system supports manual, automatic, and remote control modes, providing flexible operation for diverse application scenarios. The system also features comprehensive safety features, such as low oil pressure alarm, high water temperature protection, overspeed protection, and start-up failure alarm, ensuring the equipment’s long-term operational safety and reliability. In terms of energy efficiency, the diesel fire pump achieves higher fuel efficiency and lower operating costs through fuel injection optimization and an airflow control system. It utilizes internationally advanced turbocharging and intercooling technologies to increase air intake and combustion efficiency, reducing energy waste. Furthermore, the pump drive system is precisely balanced for low vibration and low noise, maintaining strong power output while reducing energy consumption and environmental noise, meeting modern energy-saving and environmental protection requirements. Regarding maintenance, the diesel fire pump features a user-friendly design and is easy to maintain. Key components such as the filter element, fuel pump, oil pump, and water pump bearings all feature quick-release mechanisms, facilitating routine inspection and replacement. The control system supports operation logging and data storage, enabling real-time monitoring of operating status and providing data support for subsequent maintenance. Furthermore, the system includes a standard communication interface for easy connection to building fire protection systems or remote monitoring platforms, enabling intelligent management and remote operation and maintenance. The materials used in this new generation of diesel fire pumps also demonstrate meticulous craftsmanship and durability. The pump body and key components are constructed from corrosion-resistant alloys and undergo high-temperature annealing and rust-proofing treatments to ensure long-term rust- and deformation-free operation. The diesel engine utilizes a high-strength aluminum alloy and cast iron construction, balancing lightweight design with stability. The cooling system, equipped with a large-capacity cooler and a high-efficiency fan, maintains the engine’s optimal operating temperature during continuous operation, extending the equipment’s lifespan. Diesel fire pumps are suitable for virtually any application requiring a highly reliable water supply. Their superior power output and independent operation make them widely used in fire protection systems in critical areas such as high-rise buildings, airports, tunnels, oil and gas storage and transportation, docks, power plants, and industrial and mining enterprises. Diesel fire pumps are particularly ideal for fire protection systems in areas with unstable power supplies or in remote locations. Whether supplying high-pressure pipe networks in urban complexes or providing emergency backup systems in industrial plants, they can instantly activate and continuously provide high-pressure water, ensuring the proper functioning of fire sprinkler and fire hydrant systems. Diesel fire pumps undergo rigorous testing and certification for operational stability. Each unit undergoes numerous performance tests before leaving the factory, including flow and head tests, continuous operation tests, startup response tests, and durability tests, ensuring optimal performance under all operating conditions. For fire protection systems, this highly reliable operational performance is fundamental to safeguarding life and property. As fire safety standards continue to rise, diesel fire pumps are also undergoing continuous upgrades and innovations. The incorporation of new technologies such as intelligent monitoring, remote control, and energy efficiency management has transformed them into more than just a pump; they are now integrated emergency water supply solutions. Overall, diesel fire pumps, with their powerful powertrain, superior structural design, advanced control technology, and exceptional energy-saving performance, hold a key position in the fire water supply industry. They can respond quickly and operate continuously under extreme conditions, ensuring a stable water supply for buildings and industrial facilities. They are an indispensable core component of modern fire protection systems. With the continuous advancement of technology and increasingly stringent environmental protection requirements, future diesel fire pumps will become more intelligent, energy-efficient, and modular, striving not only for superior performance but also for continuous improvements in safety and sustainability, continuing to be a solid force in safeguarding fire safety.