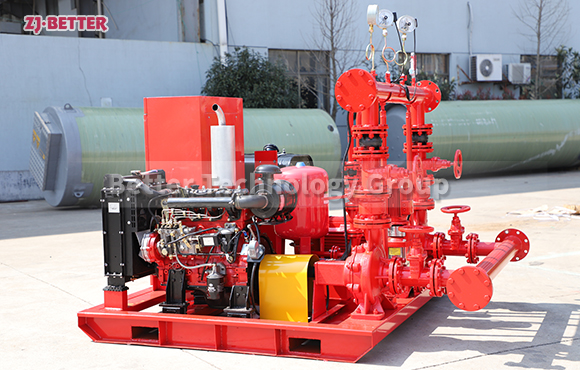

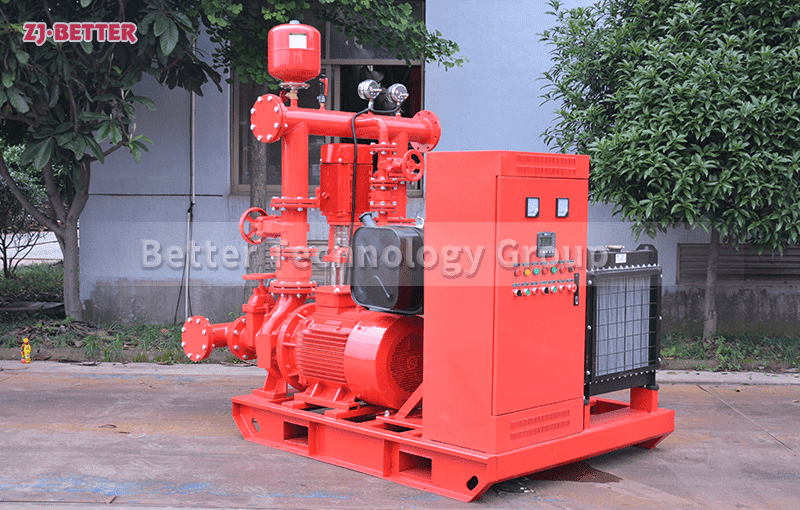

Diesel Fire Pump for Ports and Large Facilities – Fast Response and Long-Lasting Power

Specialized diesel fire pumps for ports and large facilities feature rapid response, long-term stable operation, high head and large flow, corrosion resistance and durability, as well as intelligent control. These pumps ensure efficient water supply in power outages or emergencies, thereby safeguarding fire safety.

Diesel fire pumps serve as the core equipment in fire protection systems for ports and large-scale facilities, leveraging their dual advantages of rapid response and sustained power to play a critical role in safeguarding lives and property. This diesel fire pump is specifically designed to meet the needs of ports and terminals, petrochemical bases, large warehousing centers, power plants, ship berths, industrial parks, and various special locations remote from municipal water supply systems. Its high-performance diesel engine-driven design ensures stable operation even in the absence of power supply or during power outages, providing reliable support for emergency rescue operations. The equipment adopts international standard design concepts and precision manufacturing processes. The power core uses high-efficiency, energy-saving industrial-grade diesel engines, featuring strong output power and excellent fuel economy. Even during prolonged full-load operation, it maintains stable performance, meeting both high-flow and high-head requirements to achieve large-scale, high-pressure firefighting water supply. The pump body is cast from corrosion-resistant, high-strength materials, with internal hydraulic components precision-balanced and optimized for flow path design to minimize hydraulic losses and enhance operational efficiency. This ensures a long service life even in corrosive environments such as seawater or salt fog. The control system is equipped with an intelligent operation panel, integrating functions such as automatic start-up, manual control, and remote monitoring. It enables the pump unit to automatically start and quickly enter operation upon receiving a fire signal, while also featuring comprehensive alarm and protection mechanisms, including low oil pressure alarms, high water temperature alarms, overspeed protection, and fuel shortage alerts, ensuring safe and reliable operation under any conditions. To meet the special requirements of ports and large-scale facilities, the diesel fire pump is designed with a focus on rapid response time. The process from receiving the start signal to entering a stable water supply state has been optimized, enabling full-power output in an extremely short time to effectively respond to sudden fires. Its fuel system features a large-capacity fuel tank design combined with low fuel consumption characteristics, enabling continuous operation for several hours or even longer, ensuring a steady supply of water during large-scale fire rescue operations. In terms of installation structure, the pump set adopts a high-strength base with an integrated welded structure, offering excellent seismic resistance and impact resistance, making it suitable for use in ports, cargo areas, shipyards, and other locations with frequent vibrations and impacts. It supports both fixed installation and sliding installation, allowing users to flexibly arrange the equipment according to on-site conditions. The pump set can also be configured with parallel or standby pumps according to customer requirements, enabling multiple pumps to operate in coordination, thereby enhancing system redundancy and reliability. In terms of maintenance, the pump set has a rational layout with conveniently located access points. Routine maintenance tasks such as oil changes, filter cleaning, and belt tension adjustments can be quickly completed, significantly reducing maintenance costs and downtime. The diesel fire pump also exhibits excellent environmental adaptability, maintaining stable performance in complex environments such as high temperatures, low temperatures, high humidity, dust, or salt fog. Even in coastal ports, tropical humid regions, or cold climates, it can be directly deployed without significant modifications. Overall, this diesel fire pump, specifically designed for ports and large-scale facilities, not only excels in terms of power performance, structural strength, durability, and response speed, but also offers users a comprehensive firefighting water supply solution through its highly intelligent control system and comprehensive safety protection features, making it a firefighting device that can truly deliver maximum effectiveness in critical situations. Whether in long-term operation areas such as port loading and unloading zones or in petrochemical storage and transportation bases requiring extremely high reliability, it leverages its sustained power and rapid response advantages to provide robust fire safety protection, helping users effectively address various fire risks and safeguard personnel and property safety.