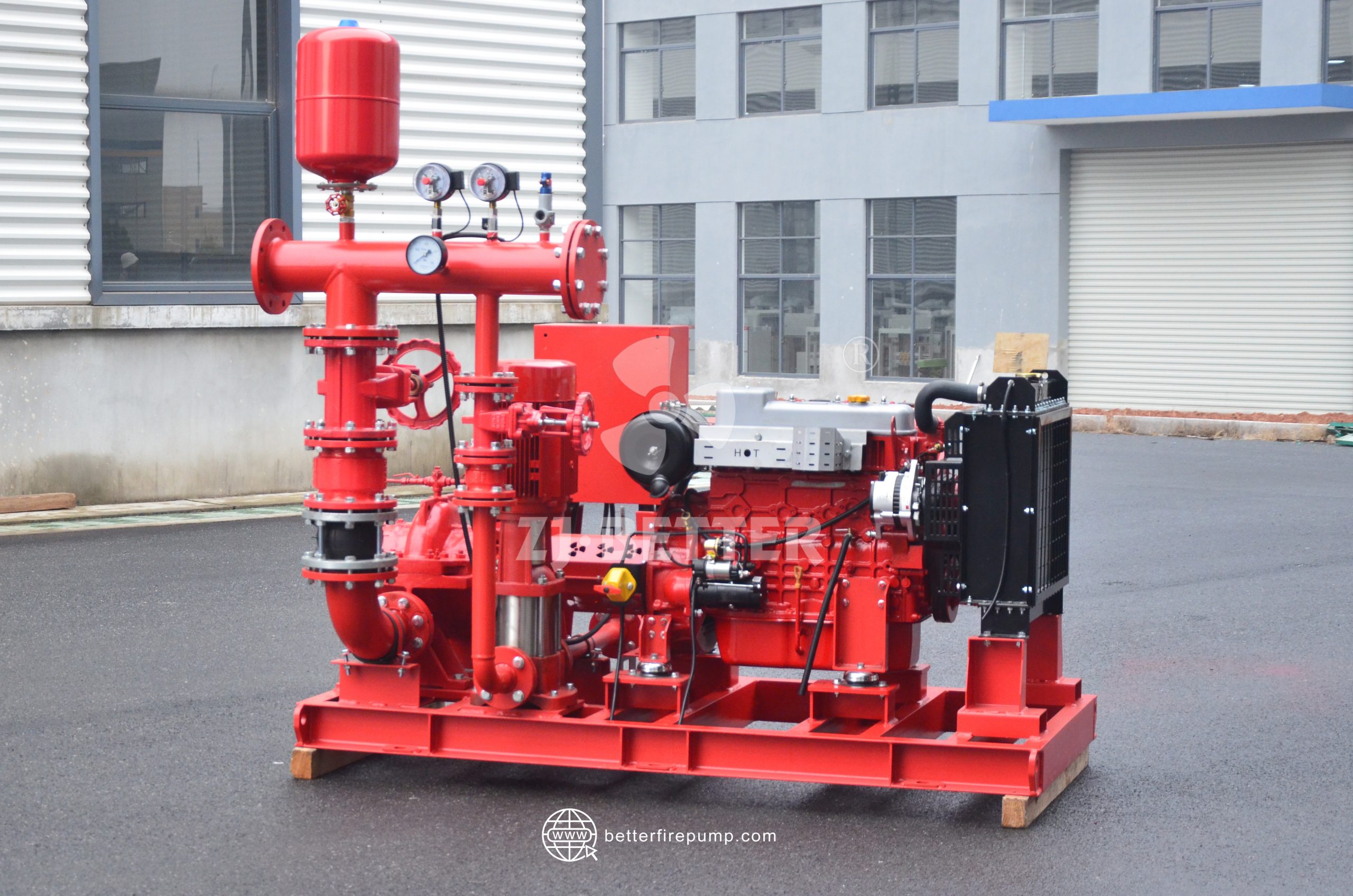

High-Efficiency Diesel Fire Pump Equipment with Stable Output and Fuel Economy

High-efficiency diesel fire pump equipment adopts a reliable diesel power system, which has the advantages of being usable during power outages, starting quickly, outputting stably, and having high fuel efficiency. It is suitable for industrial plants, warehouses, petrochemical facilities, and emergency fire-fighting scenarios, balancing high flow and high head with energy-saving operation, ensuring safe and reliable fire water supply in critical moments.

High-efficiency diesel fire pumps are designed with stable output and energy-saving operation as core objectives. They are specifically designed for locations with extremely high requirements for reliable fire water supply. In the event of a sudden fire, emergency rescue, or in environments without mains power or with unstable power, they can continuously, stably, and efficiently provide sufficient fire water, making them an indispensable component of modern fire protection systems. These diesel fire pumps use mature and reliable diesel engines as their power source. Compared to electric drive systems, they do not rely on external power conditions. Even in the event of a power outage, line damage, or in remote areas, they can quickly start and maintain stable operation, fundamentally improving the safety redundancy capability of the fire protection system under extreme conditions. The entire system is designed with a balance between energy efficiency and output in mind. Through precise matching of the diesel engine power curve and the pump’s operating point, the pump unit always operates in a high-efficiency range within the rated speed range, avoiding ineffective energy consumption and power waste. This ensures high flow and high head output while effectively reducing fuel consumption and optimizing long-term operating costs. In terms of structural design, this diesel fire pump typically employs direct-drive or high-strength coupling connections to reduce intermediate transmission losses, resulting in high transmission efficiency, smoother operation, and effective control of mechanical vibration and noise. This not only improves overall energy efficiency but also significantly extends the service life of bearings, seals, and critical moving parts. The pump body is mostly made of high-strength cast iron or alloy materials, and the internal flow channels are optimized using a hydraulic model to reduce hydraulic losses and eddy currents, ensuring smoother water flow. Even under high load conditions, it maintains stable pressure output, thus ensuring sufficient water volume and pressure at the end of the fire protection network. Considering the specific needs of fire protection applications, this type of equipment has been significantly enhanced in terms of starting performance. The diesel engine has excellent cold-start capability, and combined with a reliable starting system and intelligent control module, it can quickly start and reach rated speed even in low temperatures, high humidity, or after prolonged standby, buying valuable time for firefighting. To achieve truly stable output, the equipment is typically equipped with multiple monitoring and protection mechanisms. These mechanisms monitor key operating parameters such as speed, oil pressure, water pressure, and temperature in real time, promptly triggering alarms or implementing protective measures in case of abnormal conditions. This prevents water supply interruptions due to equipment failure, thereby comprehensively improving the safety and reliability of the system. Energy-saving operation is another core advantage of this diesel fire pump. By optimizing the combustion system and intake/exhaust structure, the diesel engine’s combustion efficiency is improved, allowing for more efficient use of fuel energy. Under the same output conditions, this effectively reduces fuel consumption per unit flow or per unit time. For fire protection systems requiring regular trial runs or long-term standby, this significantly reduces long-term operating costs. Simultaneously, a well-designed cooling system ensures the diesel engine maintains an ideal operating temperature under high loads, preventing efficiency drops or component damage due to overheating. This further enhances overall energy efficiency while ensuring stable output. In practical applications, high-efficiency diesel fire pumps are widely used in industrial plants, warehousing and logistics centers, petrochemical facilities, high-rise buildings, transportation hubs, and various temporary or mobile fire protection scenarios. Their independent power supply characteristics and stable, reliable performance make them irreplaceable in emergency fire protection systems. The equipment also embodies a design philosophy oriented towards efficiency and practicality in terms of installation and maintenance. Its compact structure and small footprint allow for flexible placement in machine rooms, containers, or mobile bases. Clear maintenance access routes and simple, efficient daily inspections and maintenance help reduce downtime and keep the equipment in optimal working condition. Overall, this high-efficiency diesel fire pump achieves an ideal balance between stable output and low energy consumption through systematic optimization of the power system, hydraulic structure, control and protection, and energy-saving operation. It not only provides reliable fire water supply in critical moments but also offers users lower operating costs and higher long-term value, making it the preferred solution for fire protection projects that prioritize safety, reliability, and economy.