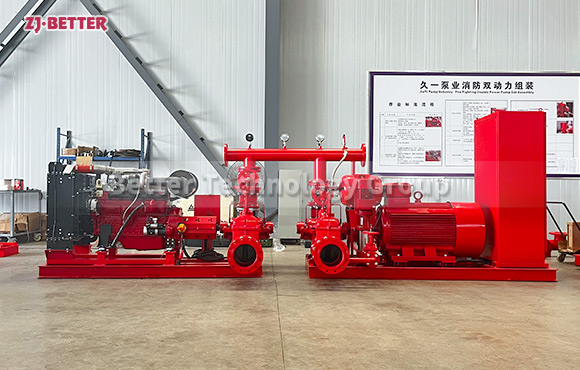

Close-Coupled Motor Fire Centrifugal Pump with Compact Space-Saving Design

The direct-drive fire centrifugal pump features a compact design, small footprint, stable and efficient operation, and is suitable for sprinkler and fire hydrant systems. It boasts advantages such as high head, large flow rate, energy saving, low noise, and convenient maintenance, providing reliable water supply for building and industrial fire protection systems.

The direct-drive centrifugal fire pump features a compact design that saves installation space. It is a high-performance core device specifically designed for modern building fire protection systems and industrial fire water supply projects. The overall design utilizes a horizontal end-suction structure and a direct-drive motor connection, integrating the motor and pump body into a single unit via a high-precision coaxial connection. This effectively reduces energy loss and mechanical deviation associated with traditional coupling structures, improves transmission efficiency, and reduces vibration and noise, significantly enhancing operational reliability while ensuring stable output. The product employs a single-stage centrifugal hydraulic model design, with the impeller undergoing precise dynamic balancing and flow channel optimization. This ensures smooth water flow within the pump chamber, reducing turbulence and hydraulic losses, thereby achieving stable output of high head and large flow rate at rated speed. It can meet the needs of various fire protection applications, including automatic sprinkler systems, indoor and outdoor fire hydrant systems, foam extinguishing systems, and pressure-stabilized water supply systems. The compact design reduces the overall footprint, making it particularly suitable for installation environments with limited space, such as high-rise buildings, commercial complexes, underground parking garages, hospitals, schools, and industrial plants. Standardized flange interfaces facilitate quick connection to existing fire protection piping networks, shortening construction time and reducing installation costs. The pump body is integrally cast from high-strength cast iron, ensuring a robust and pressure-resistant structure. Internal flow components can be made of corrosion-resistant stainless steel depending on the water quality, effectively improving corrosion resistance and wear resistance, maintaining excellent performance even under long-term operation and frequent start-stop conditions. The shaft sealing system uses a high-quality mechanical seal structure with a high-temperature and wear-resistant design, ensuring excellent sealing performance under high-pressure operation, reducing leakage risk, and guaranteeing safe and reliable start-up of the fire protection system in critical moments. The motor is a high-efficiency, energy-saving, fully enclosed, air-cooled motor with good insulation and heat dissipation capabilities, meeting the dual requirements of long-term standby and emergency continuous operation of the fire protection system. It quickly reaches rated speed during a fire, achieving instantaneous and efficient water supply. By optimizing the pump shaft material and bearing configuration, using high-strength alloy steel shafts and high-precision bearing components, friction loss and axial movement are effectively reduced, improving mechanical stability and extending the overall service life of the machine. The base structure adopts a thickened steel plate welding design, combined with shock-absorbing pads and precise alignment installation, effectively reducing the impact of operating vibration on the building structure while ensuring long-term stable operation of the equipment. This fire-fighting centrifugal pump fully considers system pressure fluctuation control during the design phase. By rationally matching the impeller diameter and motor power, it maintains stable output in different flow ranges, avoiding water hammer impact caused by sudden changes in water pressure and protecting the safety of the fire-fighting pipeline network. Before leaving the factory, the products undergo rigorous water pressure testing, performance testing, and dynamic balancing inspection to ensure that each unit meets design standards under rated operating conditions, with stable and reliable performance parameters. Flow rate, head, and power configuration can be adjusted according to different project requirements to achieve customized matching. Its efficient hydraulic model not only improves water supply efficiency but also reduces energy consumption. It maintains a low-power operation mode during routine inspections or pressure stabilization, and rapidly increases output capacity in emergency fire-fighting situations, achieving both energy saving and high efficiency. The equipment supports integration with fire control cabinets, pressure sensors, and automatic control systems, enabling automatic start/stop and remote monitoring, thus improving the overall intelligent management level of the fire protection system. Due to its direct-drive motor structure, it reduces intermediate transmission components, making maintenance more convenient, and the disassembly and assembly process is simple and efficient, shortening maintenance time and reducing maintenance costs, making it suitable for long-term use in large-scale projects. The entire machine surface is treated with industrial-grade anti-corrosion coating, possessing excellent oxidation resistance and weather resistance, adapting to humid, high-temperature, or dusty environments, ensuring stable operation under complex industrial conditions. In high-rise building fire protection systems, this product can be used as a main pump or a pressure-stabilizing water supply pump. In industrial plants and warehousing and logistics centers, it can be connected in parallel with multiple pumps to form a fire pump group system, achieving graded flow control and redundant backup design, improving system safety. In municipal fire protection projects, its stable head output capacity can effectively cover long-distance water supply needs, ensuring that terminal fire protection facilities reach the design pressure. The compact design not only saves installation space but also facilitates future expansion and renovation. When the project scale expands or fire protection standards are upgraded, the system can be upgraded by increasing the number of pump groups without large-scale structural adjustments. With low operating noise and vibration, this product is particularly suitable for public building projects with high environmental requirements. Through scientific fluid dynamics design and strict production process control, this direct-drive fire centrifugal pump ensures fire safety while also being energy-efficient, cost-effective, and practical, providing reliable water supply for various building fire protection projects. Its stable and durable structure, optimized hydraulic performance, and energy-efficient operation mode enable it to maintain excellent performance under complex and ever-changing fire protection conditions, laying a solid foundation for building safe and reliable fire water supply systems in modern buildings and industrial sites. It is a crucial core device for improving the overall safety level and operational efficiency of fire protection systems.

-2.jpg)