How to Ensure Fire Pump Reliability in Emergencies

Learn best practices to ensure your fire pump operates reliably during emergencies, including maintenance tips, testing procedures, and system checks.

Fire pumps are a critical part of any building’s life safety system. In an emergency, their ability to start and perform instantly can mean the difference between disaster and protection. However, reliability doesn’t happen by chance—it requires regular testing, diligent maintenance, and smart system design.

In this article, we’ll cover essential steps to ensure your fire pump works flawlessly when it’s needed most.

1. Follow a Routine Maintenance Schedule

The most important factor in ensuring reliability is consistent maintenance. According to NFPA 25, building owners should implement weekly, monthly, and annual inspections, including:

-

Weekly churn tests (no-flow tests)

-

Monthly valve inspections

-

Quarterly alarm signal checks

-

Annual full flow performance testing

A detailed maintenance log should be kept, documenting all inspections and repairs.

2. Perform Weekly Fire Pump Tests

The fire pump must be started and run weekly to ensure it’s operational. For electric pumps, this test typically lasts 10 minutes; for diesel pumps, at least 30 minutes (per NFPA 25).

During the test:

-

Record system pressures

-

Listen for abnormal noise or vibration

-

Confirm automatic start functionality

-

Inspect for fuel, oil, or coolant leaks (diesel pumps)

Regular testing helps identify issues before they become emergencies.

3. Verify Automatic Start Features

Fire pumps should start automatically in response to low system pressure. This function should be verified during tests. Make sure:

-

The pressure switches are properly calibrated

-

The controller is set to auto mode

-

The backup power system (if applicable) is functional

If automatic start fails, the pump may not operate during an actual fire event.

4. Test Emergency Power Supplies

If your system uses electric fire pumps, a reliable power source is essential. Ensure:

-

Emergency generators are tested under load

-

Automatic Transfer Switches (ATS) function correctly

-

Fuel tanks for generators are full and clean

Loss of power is common during fires and storms—your fire pump must be able to run under all conditions.

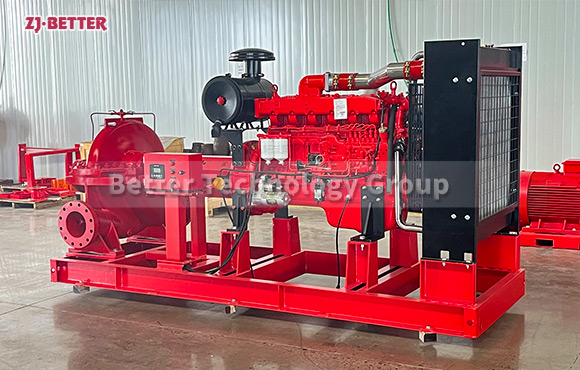

5. Keep Diesel Fire Pumps Fully Operational

Diesel-driven pumps require extra attention to ensure emergency readiness:

-

Fuel levels and fuel quality must be monitored regularly

-

Coolant heaters and battery chargers should be inspected

-

Block heaters must be operational in cold climates

Replace fuel every 12 months to prevent diesel degradation, and keep spare filters and parts on hand.

6. Monitor Pump Room Conditions

The pump room environment affects equipment reliability. Make sure:

-

Room temperature stays between 40°F to 120°F (4°C to 49°C)

-

Ventilation is adequate to prevent overheating

-

Humidity is controlled to avoid corrosion

-

No water leaks or debris are present around electrical systems

Clean, dry, and well-lit rooms support optimal performance and quick troubleshooting.

7. Train Staff for Emergency Response

Operators and maintenance staff must understand:

-

How to manually start the fire pump

-

How to respond to alarm signals

-

How to safely operate pump controllers

-

Who to contact in case of malfunction

A trained team can prevent small issues from escalating during an emergency.

8. Inspect Fire Pump Controllers

Controllers are the brain of the fire pump system. Inspect and test:

-

All indicators and alarms

-

Start/stop mechanisms

-

Pressure sensors and timers

If the controller fails, the pump won’t run—even if everything else is in perfect condition.

Conclusion

Fire pump reliability isn’t just about the hardware—it’s about how the system is maintained, tested, and managed. With consistent weekly testing, proper controller settings, reliable power backup, and trained personnel, you can ensure your fire pump activates instantly during a real emergency.

Remember, a fire pump that doesn’t start when needed isn’t just a maintenance issue—it’s a life safety risk.