Performance Analysis of High-Efficiency Electric Fire Pump Units for Industrial and Commercial Buildings

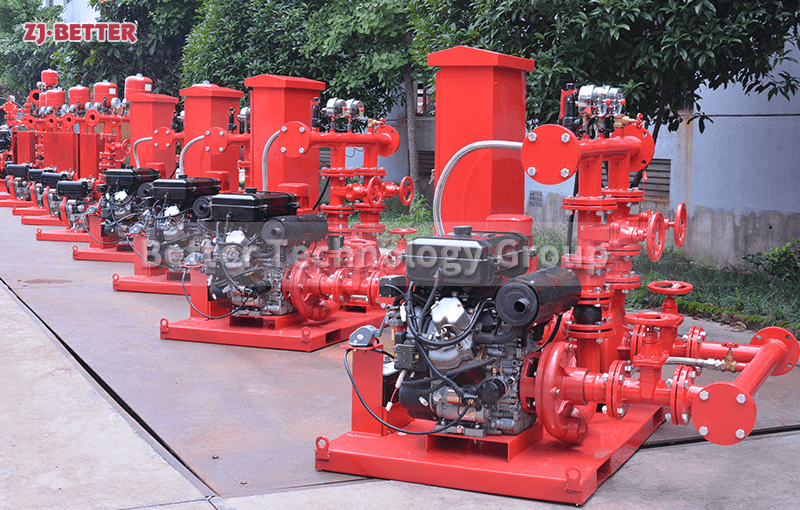

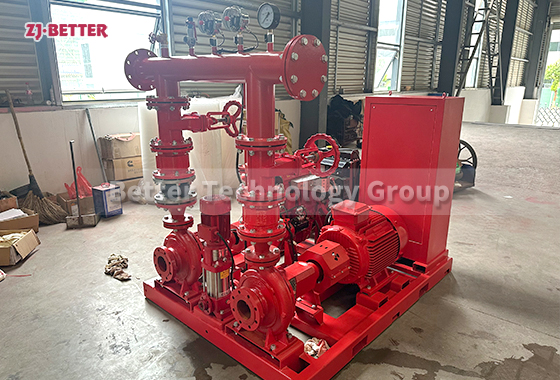

High-efficiency electric fire pump units are designed for industrial and commercial buildings, featuring high flow rate, strong stability, and intelligent control functions, providing rapid response and continuous reliable fire water supply.

High-efficiency electric fire pump units for industrial and commercial buildings are core equipment specifically designed to provide stable fire-fighting water supply for large-scale infrastructure, modern building complexes, and critical industrial scenarios. Driven by a high-performance electric motor, combined with a high-efficiency pump hydraulic structure, reinforced mechanical design, and intelligent control system, they achieve advantages such as rapid response, stable pressure supply, and long-term continuous operation. With accelerated urbanization and increasingly stringent building fire safety regulations, these electric fire pump units have become indispensable fire-fighting power sources in large factories, commercial complexes, logistics warehouses, energy facilities, underground spaces, and high-rise buildings. From an engineering application perspective, the overall performance of high-efficiency electric fire pump units far surpasses that of traditional pumps, particularly in stability, energy efficiency, reliability, durability, and intelligent control. They are among the most common and critical water supply equipment in fire protection engineering. One of the core advantages of electric fire pump units is their stable and reliable power output. The high-efficiency electric motor employs an optimized electromagnetic structure and reinforced winding design, exhibiting extremely high stability during startup, acceleration to rated speed, and continuous operation, preventing pressure instability caused by power fluctuations. The high torque characteristic of electric motors allows pumps to establish pressure instantly upon startup, meeting the response speed requirements of fire protection networks. This rapid and stable power output is crucial for large commercial buildings, industrial sites, and high-rise buildings, as the primary requirement for fire protection systems during a fire is rapid startup and continuous water supply. High-efficiency electric fire pump units also offer significant advantages in hydraulic performance. The pump body employs an optimized volute structure, impeller curve, and flow channel shape, minimizing water flow losses and enabling higher flow rates and heads under the same power conditions, significantly improving energy efficiency. For industrial buildings, large warehousing centers, and logistics parks requiring high-flow-rate, long-distance water delivery, the pump’s high head and high flow rate ensure stable water supply, guaranteeing the continued operation of the entire fire protection network under peak pressure demands. Furthermore, the pump body is typically made of high-strength cast iron or other corrosion-resistant alloys, with reinforced shaft seals and sealing structures, giving the equipment strong wear resistance and a long service life, adapting to the high-load, long-cycle operation requirements of industrial environments. Energy efficiency is a crucial design indicator for modern fire pumps. High-efficiency electric fire pump units, through the use of high-efficiency motors, low-resistance hydraulic components, and optimized matching designs, significantly reduce energy consumption while meeting fire safety requirements. For buildings that need to remain on standby year-round and occasionally undergo trial runs, this energy-saving advantage not only reduces daily energy consumption but also lowers operating costs, aligning with the trends of green building and energy-saving engineering. Furthermore, some units can be equipped with intelligent variable frequency systems, enabling them to participate in pipeline pressure stabilization during non-fire conditions, thus reducing the frequency of main pump starts, significantly extending equipment lifespan, and further reducing energy consumption. The control system of high-efficiency electric fire pump units is also a key advantage. Control cabinets are typically equipped with automatic, manual, and remote control modes, capable of automatically starting and stopping the pump based on changes in pipeline pressure. The automatic operation mode relies on pressure switches or pressure sensors to monitor the system status in real time, automatically starting the pump when the pipeline pressure drops to a set value and automatically stopping it after the pressure recovers, ensuring the system is always responsive. Manual mode is used for commissioning or maintenance, while remote control can connect to intelligent building management systems or fire control centers to achieve centralized monitoring, status feedback, and fault alarms, significantly improving the automation level of the overall building fire protection system. In addition, the high-efficiency electric fire pump unit has comprehensive self-protection functions, including phase loss protection, overload protection, short circuit protection, overvoltage and undervoltage protection, and motor temperature rise protection, ensuring that the equipment automatically alarms or shuts down in abnormal conditions, reducing fault damage and improving safety. Besides stability and intelligence, durability is a crucial characteristic of this type of pump. The pump body structure is reinforced, and the bearings, couplings, and mechanical seals are all made of highly wear-resistant materials, enabling it to withstand long-term continuous operation and maintain stable performance. Industrial environments often present adverse factors such as large temperature differences, high humidity, and heavy dust. The high-efficiency electric fire pump unit, through enhanced structural protection, coating treatment, and improved protection levels, can maintain reliable operation in harsh environments, ensuring its long-term role as a core power equipment in the fire protection system. Furthermore, the entire unit integrates the pump, motor, and coupling through an integral welded base structure, making installation more stable, less prone to vibration, and maintaining structural stability during transportation and hoisting. Ease of maintenance is also a key concern for engineering clients. The high-efficiency electric fire pump unit adopts a modular design, making the pump body, coupling, motor, base, and control system easy to disassemble and inspect. Routine maintenance only requires conventional checks of the bearings, mechanical seals, and internal pump components, saving significant maintenance time and costs. Simultaneously, the unit features standardized interfaces and installation methods, facilitating rapid deployment in industrial plants, underground machine rooms, or commercial building pump rooms without complex construction. Furthermore, the pump’s operation indicators and control parameter displays are simple and intuitive, allowing maintenance personnel to easily monitor the equipment’s operating status. The high-efficiency electric fire pump unit has a wide range of applications. Its powerful water delivery capacity and high stability make it suitable for high-rise building fire protection systems, commercial complexes, large fire protection networks in factories and manufacturing workshops, warehousing and logistics centers, petrochemical plants, shipyards, power plants, and supporting facilities. For applications requiring long-distance, high-lift water delivery, the unit can be paired with booster pumps, pressure-stabilizing pumps, or dual-pump systems to meet different pressure requirements. For large-scale building projects, units with different flow combinations can be designed according to the main pipeline layout to meet the fire water supply needs of multi-story, multi-zone, and multi-circuit systems. In summary, high-efficiency electric fire pump units specifically designed for industrial and commercial buildings have become one of the most important core equipment in modern fire protection systems due to their stable power output, high hydraulic performance, excellent energy efficiency, advanced control systems, outstanding durability, and convenient installation and maintenance. With the continuous upgrading of fire protection standards, industrial automation, and intelligent building technologies, these electric fire pump units will continue to be widely adopted globally and play an even more crucial role in ensuring the safety of people and building property. Their importance in future building and industrial fire protection will only continue to increase.