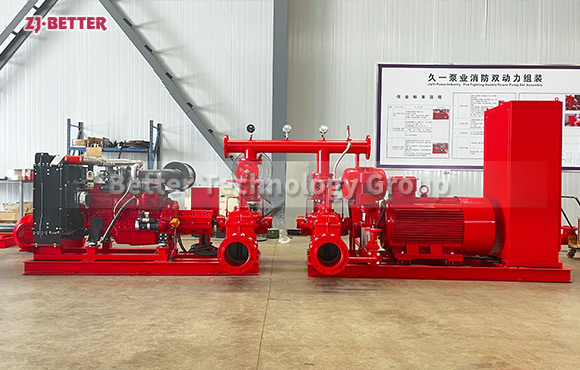

Diesel engine fire pumps are more and more widely used

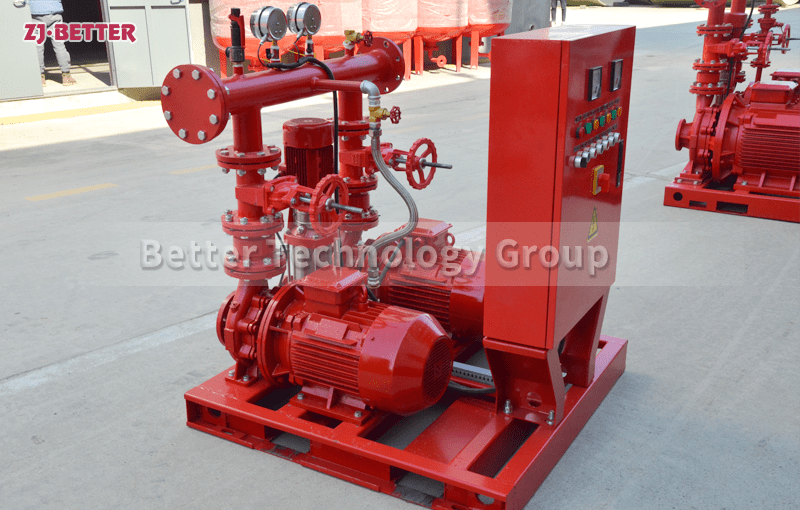

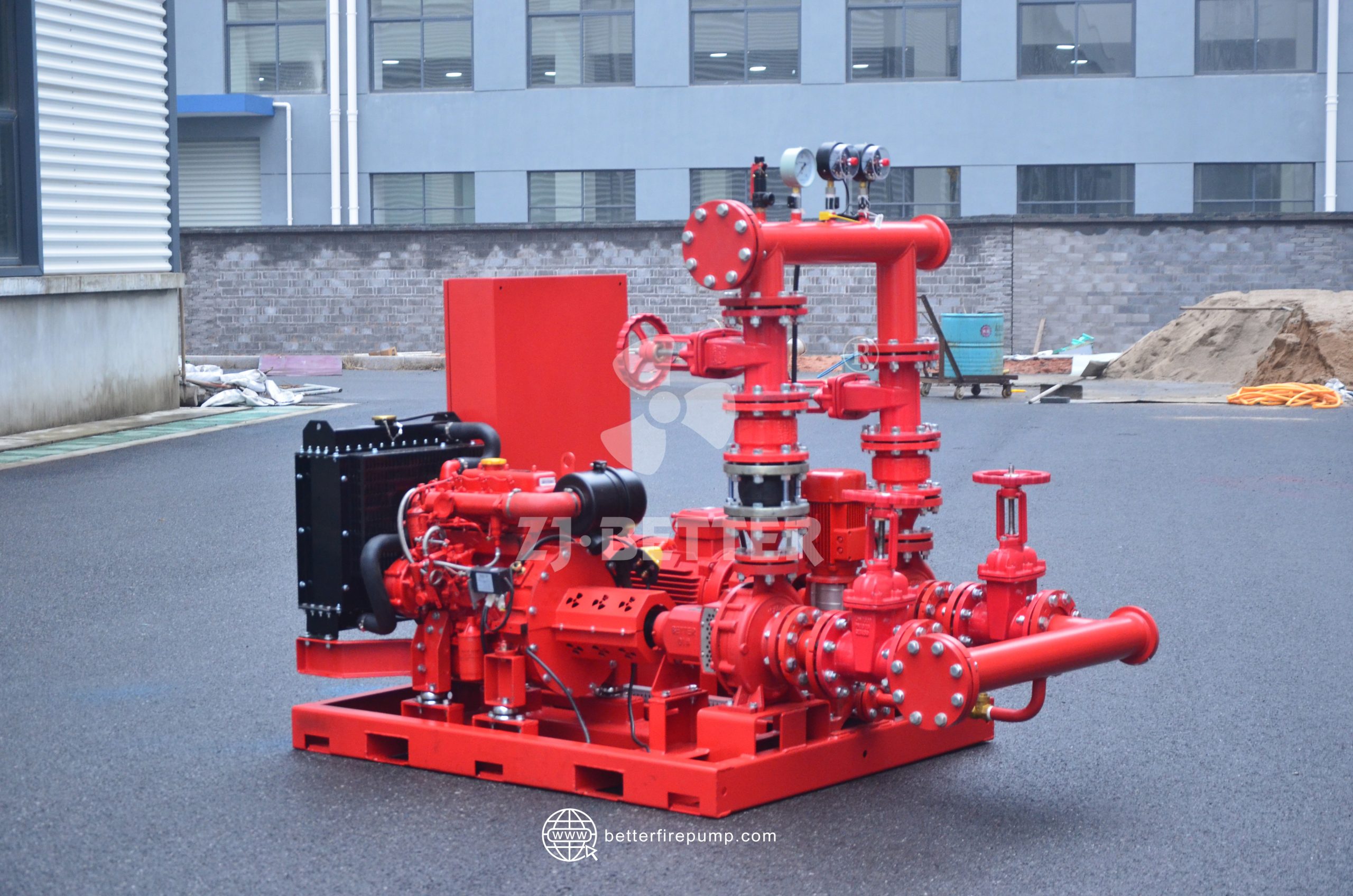

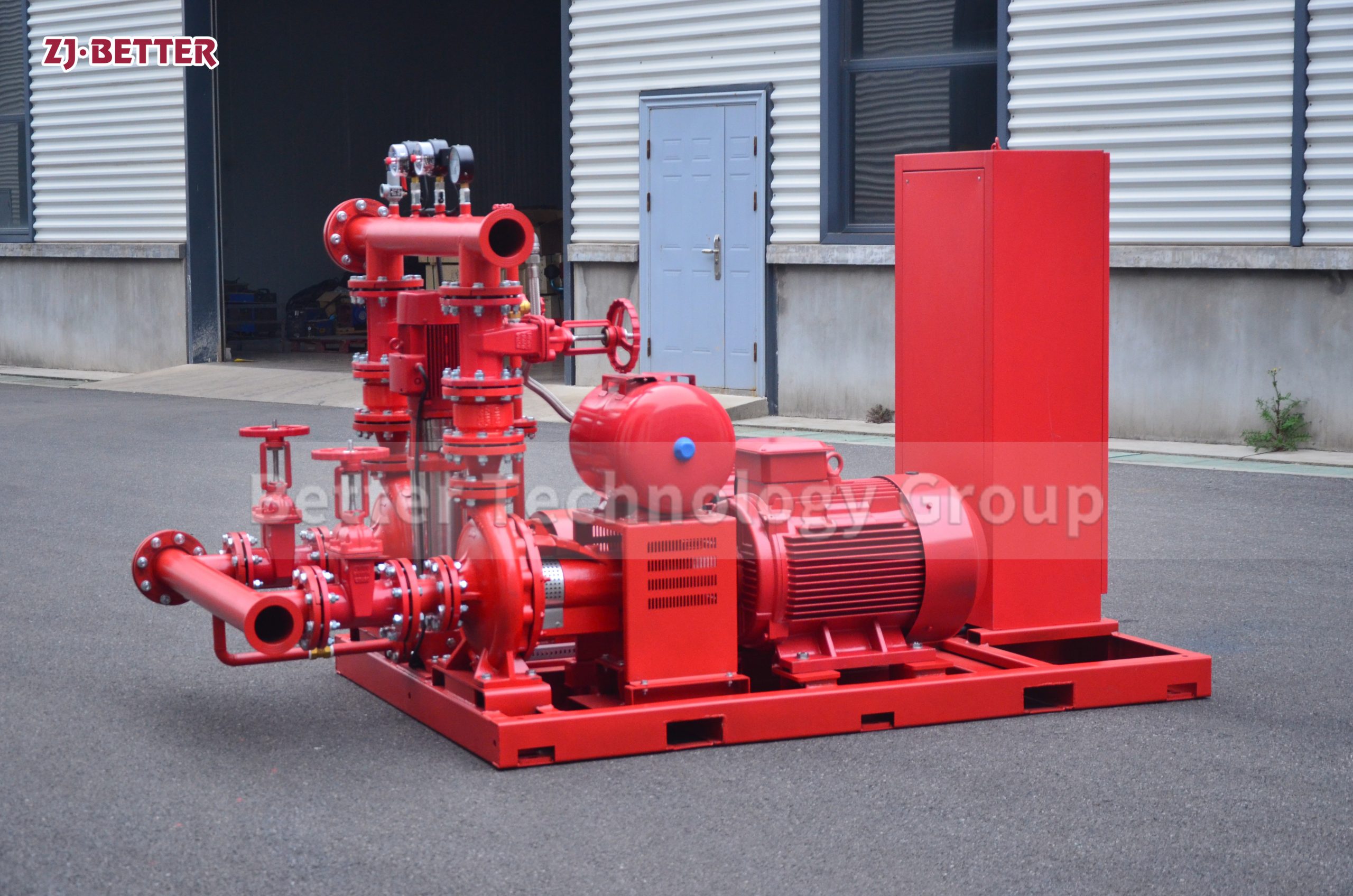

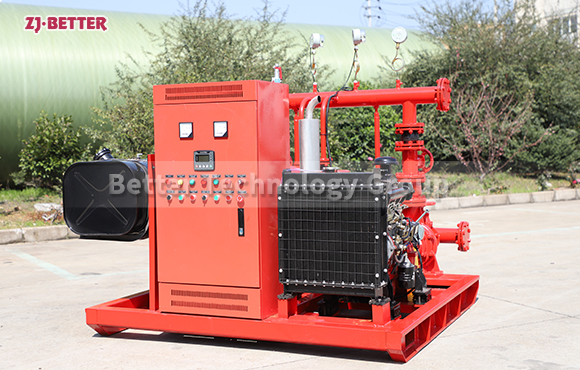

Diesel engine fire pumps are used more and more widely. Diesel engine fire pump is a common and necessary facility. Only when the fire signal comes, and the electric water pump fails or the power supply is cut off, the diesel engine fire pump will automatically start. Diesel engine fire pump is installed together with electrical instruments, with complete functions, compact structure, automatic fault alarm, receiving start signal, and can automatically complete the start-up procedure and fast full-load operation. , Enough to ensure that the diesel engine fire pump is started in a low temperature environment, the whole system of the diesel engine fire pump is safe, reliable, and easy to use.

There are three main control methods for diesel engine fire pumps:

1. Manual control: The diesel engine fire pump manually presses the control button, and the operation process is automatically completed by the preset program.

2. Automatic control: When the diesel engine fire pump is affected by fire protection, pipeline pressure or other automatic control signals, the preset program of the diesel engine fire pump will be automatically completed.

3. Remote control: The computer will perform remote monitoring, remote control, remote communication, and remote adjustment in real time through the network.