Small-flow constant-pressure fire pumps are indispensable auxiliary equipment in modern fire protection systems, playing a crucial role in maintaining stable pipeline pressure and ensuring the system is always ready to start. With the continuous expansion of building scale and the upgrading of fire protection system technology, more and more projects are beginning to emphasize the strategic significance of pressure stabilizing equipment within the entire fire protection system. Small-flow constant-pressure fire pumps are primarily responsible for maintaining stable pressure in the fire pipeline network when there is no fire. They compensate for pressure drops caused by pipeline leaks, valve micro-leakage, or static pressure losses by providing a small amount of water replenishment, thereby ensuring that the main fire pump can truly achieve “pressure drop start” in emergency situations, ensuring rapid response and reliable operation. Their design philosophy is to maintain the fire protection system in optimal standby condition for extended periods with extremely low flow rates, stable pressure output, and a highly efficient automatic control system. This allows the entire system to quickly enter working mode in the early stages of a fire, providing strong support for seizing the golden time for fire suppression. Small-flow constant-pressure fire pumps generally adopt vertical or horizontal structures, featuring small footprint, low operating noise, and flexible installation. They can also be equipped with motor drives, frequency converters, pressure sensors, and automatic control cabinets to achieve fully automatic start/stop and closed-loop pressure control. Benefiting from its high-precision pressure maintenance capability, this type of equipment is widely used in high-rise buildings, commercial complexes, hospitals, hotels, industrial plants, warehousing centers, underground parking lots, and various fixed fire extinguishing systems. With technological advancements, small-flow constant-pressure fire pumps are increasingly upgrading towards intelligence and energy efficiency, and their performance advantages have become a crucial guarantee for the stable operation of fire protection systems.

In terms of performance characteristics, the most prominent advantage of small-flow constant-pressure fire pumps is their stable constant-pressure output capability. Their core performance advantage stems from precise hydraulic model design and efficient motor drive technology. By optimizing the pump body structure, impeller curve, and flow channel angle, they maintain stable pressure output even under low-flow conditions, avoiding common problems such as excessive pressure fluctuations, discontinuous output, or frequent start-stop cycles. Stable pressure is crucial for fire protection pipe networks because pressure fluctuations can lead to false alarms or false starts, and even cause the main pump to operate repeatedly, resulting in unnecessary energy consumption in the absence of a fire. The design of small-flow constant-pressure fire pumps allows them to achieve high-stability output within a very small flow range, ensuring reliable long-term operation without impacting the pipe network.

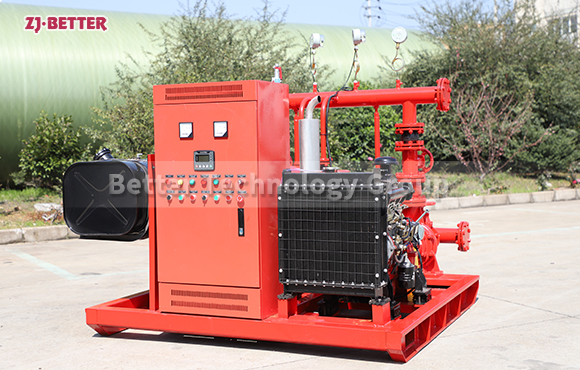

Secondly, small-flow constant-pressure fire pumps possess highly automated operation characteristics. Traditional pressure stabilization methods may rely on manual inspection or mechanical pressure switches, while modern small-flow constant-pressure pumps typically employ electronic pressure sensors, adjustable pressure controllers, intelligent control panels, and automatic start-stop logic to achieve fully automatic pressure monitoring and water replenishment. When the pressure drops to the set lower limit, the equipment automatically starts pressure replenishment; when the pressure recovers to the upper limit, it automatically stops operating. This intelligent logic not only improves operational reliability but also significantly reduces manual maintenance costs, enabling the fire protection system to achieve 24/7 automatic monitoring. Some equipment can also achieve remote monitoring, system fault self-diagnosis, automatic alarm, and self-protection functions, improving overall safety.

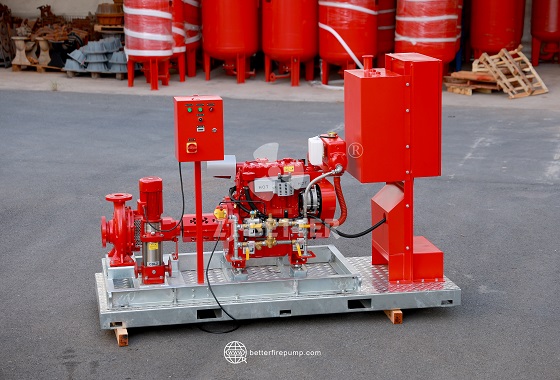

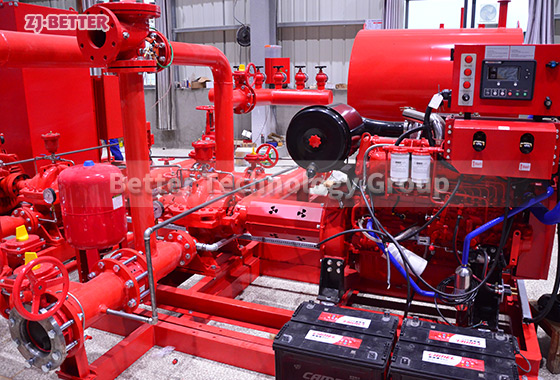

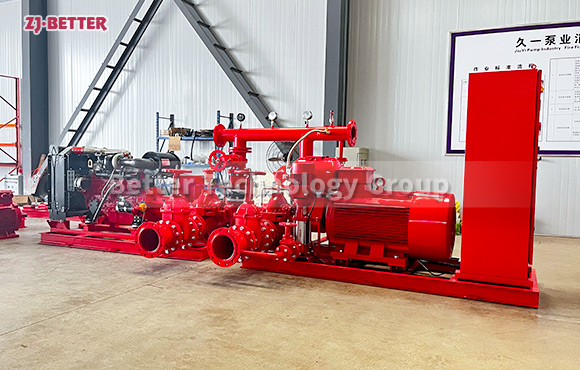

In terms of structural design, small-flow constant-pressure fire pumps typically adopt a vertical structure to reduce space occupation, especially suitable for buildings with limited pump room area. The vertical design is not only compact but also has a short axial dimension, low center of gravity, strong operational stability, low noise, and low vibration. The direct-drive structure between the pump body and motor reduces energy loss, improves efficiency, and reduces mechanical wear caused by coupling misalignment. For projects with complex installation environments, horizontal or integrated pressure-stabilizing units can be selected, integrating the pump, piping, valves, pressure tank, and control cabinet onto a single base. This offers plug-and-play convenience and significantly improves construction efficiency.

In terms of selection, the choice of small-flow constant-pressure fire pump needs to be comprehensively determined based on parameters such as the characteristics of the building’s fire protection system, pipeline capacity, pressure rating, system height difference, static pressure requirements, and leakage. Generally, the flow rate requirement is typically controlled within the range of 0.3–5 m³/h, while the pressure is generally calculated based on the main pump’s starting pressure and the system design pressure. The pump’s head margin must also be considered during selection to ensure that the equipment continues to meet requirements after long-term operation. Simultaneously, key indicators such as the pump’s sealing type, bearing life, motor rating, corrosion resistance, and pump body material should be carefully considered to ensure stable and reliable operation under long-term high-intensity conditions. For long-distance or high-rise buildings, the pump’s pressure response speed, water hammer prevention design, and pressure stabilization capability should be emphasized to ensure pipeline pressure stability.

Small-flow constant-pressure fire pumps also have significant advantages in terms of energy consumption. Its motor typically employs a high-efficiency rating to adapt to low-flow, high-head operating conditions, ensuring the lowest possible operating costs. Due to its small pressure-replenishing flow and low operating frequency, its overall energy consumption is extremely low, making it one of the most energy-efficient components in a fire protection system. With the development of energy-saving technologies, some pressure-stabilizing pumps can incorporate variable frequency control to maintain pressure through speed regulation, further reducing energy consumption and extending pump life. Simultaneously, to prevent frequent starts from shortening motor life, advanced control logic automatically sets a minimum downtime or a delayed stop function, making equipment operation more stable.

Small-flow constant-pressure fire pumps possess excellent durability. Their pump bodies are often made of cast iron, stainless steel, or special corrosion-resistant materials to resist corrosion under long-term static pressure conditions; the shaft seal uses a mechanical seal or multiple sealing structure to effectively improve leak-proof performance; the motor features thickened insulation, improved protection level, and waterproof and dustproof design, making it suitable for long-term standby conditions. To ensure stable operation, small-flow constant-pressure fire pumps are equipped with multiple electronic safety functions, including overload protection, phase loss protection, overheat protection, and low-pressure alarms. These functions enable automatic shutdown in unexpected situations to protect the overall system safety.

The value of small-flow constant-pressure fire pumps lies in their ability to ensure the fire protection system is always ready to start. Since main fire pumps are typically not frequently operated, without pressure stabilization measures, pipeline pressure may gradually decrease due to micro-leakage, leading to accidental start-up of the main pump or failure to reach the required pressure in the shortest possible time when a fire occurs. Small-flow constant-pressure fire pumps continuously maintain system pressure, providing a stable starting environment for the main pump. This allows it to quickly enter working condition during a fire, ensuring rapid water delivery from sprinkler systems, fire hydrant systems, and hose reel systems, thereby significantly improving fire extinguishing efficiency.

In summary, small-flow constant-pressure fire pumps, with their advantages of stable pressure, reliable operation, high degree of automation, compact structure, convenient installation, low energy consumption, and long service life, have become an indispensable and important component of modern fire protection systems. With the increasing prevalence of intelligent buildings and smart fire protection systems, the development of small-flow constant-pressure fire pumps will place greater emphasis on intelligent monitoring, remote operation and maintenance, energy-saving optimization, and system integration, giving them higher design value and application potential. Their key function in fire protection systems is not only maintaining pressure but also ensuring the response speed of the entire fire extinguishing chain, making them a crucial piece of equipment for ensuring fire safety. For all types of buildings, choosing a high-performance small-flow constant-pressure fire pump means choosing higher system stability, faster response speed, and lower long-term operation and maintenance costs, thus creating a safer, more efficient, and more reliable core for the fire protection system.

.jpg)