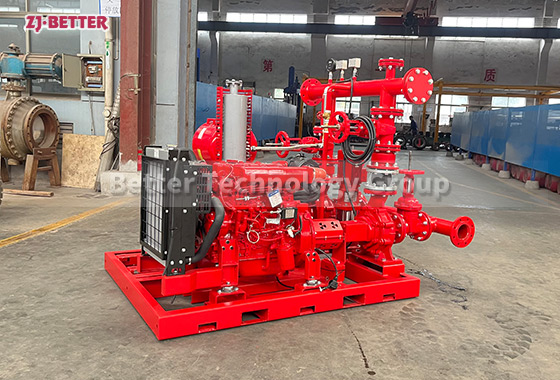

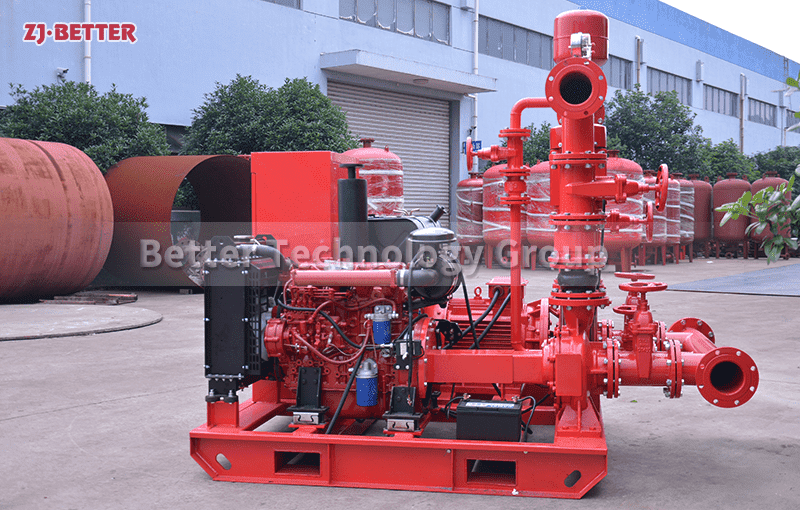

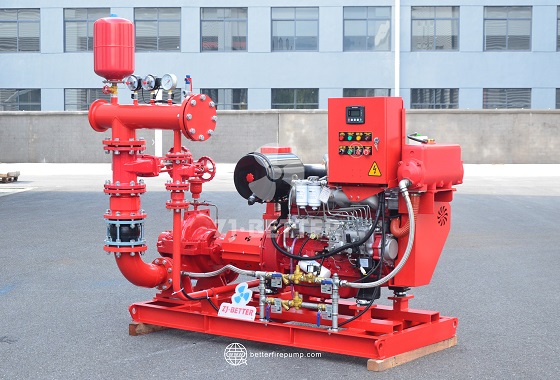

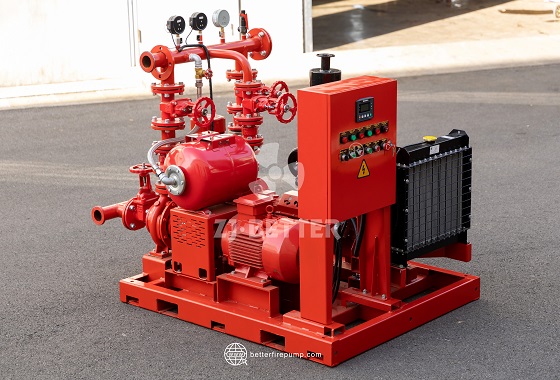

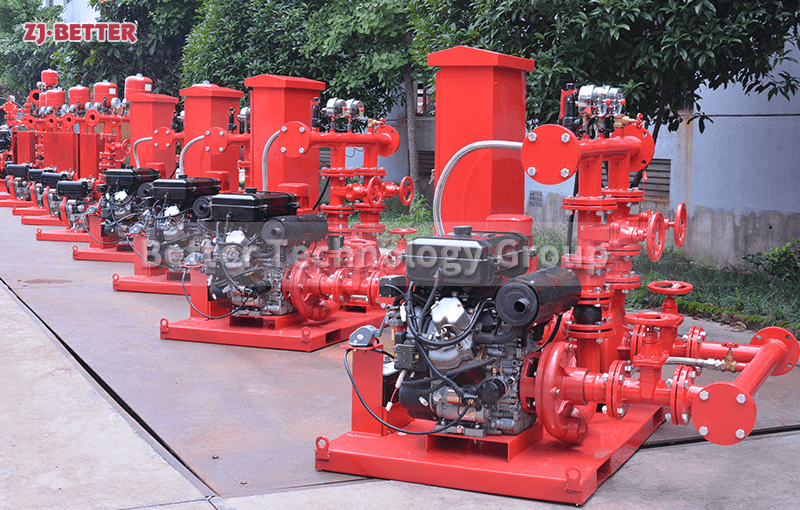

Reliable Diesel Fire Pump System: Long-Term Support for All Firefighting Projects

Diesel fire pump systems provide reliable, independent power for emergency firefighting when electricity fails. With strong performance, automatic start, high pressure, and durable design, they ensure continuous water supply for high-rise buildings, factories, chemical plants, and remote areas. Ideal for dependable fire protection and energy-efficient operation.

As a core component of fire water supply systems in modern buildings and industry, diesel fire pump systems, with their reliable performance and independent power advantages, have become a vital component in ensuring fire safety. In emergencies such as fires, where power may be interrupted, diesel fire pump systems can operate independently without external power supply, providing a continuous and stable high-pressure water supply to the entire firefighting system. This ensures timely activation of systems such as fire sprinklers, fire hydrants, and foam fire extinguishing, effectively controlling the fire and minimizing property damage and casualties. These fire pump systems utilize a high-performance diesel engine and a highly efficient centrifugal pump design, enabling high-lift, high-flow, and stable water supply in a variety of complex environments. The diesel engine is directly connected to the pump via a flexible coupling, resulting in high transmission efficiency, minimal energy loss, and rapid startup response. They maintain efficient operation even in harsh environments such as low temperature, high humidity, dust, and vibration. The system features a compact design, a small footprint, and flexible installation. Customizable to meet site requirements, the system can be quickly deployed, whether installed in a fixed fire pump room or as a mobile emergency firefighting unit. The control system utilizes a fully automatic intelligent control mode, enabling automatic detection, automatic start-up, and automatic switching. In the event of a main power failure or the electric fire pump’s inability to start, the diesel fire pump system immediately takes over water supply duties, requiring no human intervention and significantly improving emergency response efficiency. The system’s core strengths lie in its high reliability and durability. The diesel engine utilizes an internationally standardized emission configuration, offering excellent combustion efficiency and economy, ensuring stable output even during long periods of continuous operation. The pump body is constructed of wear-resistant cast iron or stainless steel, and the impeller is dynamically balanced for smooth operation with low noise and vibration. A mechanical seal prevents leakage, ensuring safety and reliability even under high-pressure conditions. All key components undergo rigorous testing and corrosion treatment, extending the life of the equipment. It is particularly suitable for use in locations requiring the highest reliability for fire protection systems, such as ports, chemical plants, warehouses, power plants, tunnels, airports, hospitals, and high-rise buildings. The diesel fire pump system offers a wide range of flow rates and head capacities, with a single unit capable of delivering flow rates of hundreds of cubic meters per hour and head capacities up to several hundred meters, fully meeting various fire water supply standards. The system’s fuel tank boasts ample capacity, enabling long-term continuous operation, typically exceeding 3 to 8 hours. It is suitable for environments with unstable power supply, such as power outages, field construction, and special firefighting sites. The diesel engine starting system utilizes electric starting, combined with automatic battery charging, to ensure rapid ignition and start-up at all times. Response times typically exceed 10 seconds, enabling rapid operation in the early stages of a fire, saving valuable time for subsequent firefighting efforts. The system also supports manual, automatic, and remote start modes, and can be linked with a fire monitoring center or building automation system (BAS) to form an intelligent fire response mechanism. Regarding safety, the diesel fire pump system features multiple automatic monitoring and protection features, including real-time monitoring of oil pressure, cooling water temperature, speed, fuel level, and battery voltage. In the event of an abnormality, the system automatically issues an alarm and takes appropriate protective measures, such as shutting down the engine or switching to backup equipment, to ensure safe operation. The control cabinet’s interior features waterproof, dustproof, and shockproof design, and electrical isolation and grounding ensure overall electrical safety. The control logic complies with international and domestic fire protection standards such as NFPA20 and GB6245, ensuring global compatibility and safety. The diesel fire pump system is designed with user convenience in mind, with all key components strategically located for easy daily inspection and maintenance. The fuel system utilizes a high-efficiency filtration structure to prevent impurities from entering the engine. The lubrication system features automatic circulation and cooling to extend engine life. The cooling system offers both air and water cooling options to accommodate diverse climates. Regular checks of the oil, coolant, and battery status ensure the equipment remains in optimal operating condition. An optional remote monitoring module provides real-time operational data, enabling users to manage equipment status and predict maintenance, significantly reducing operational costs. In addition to performance and reliability, the diesel fire pump system also boasts exceptional energy efficiency. Optimized fuel injection and combustion control technologies significantly improve the thermal efficiency of the diesel engine, providing strong power while effectively reducing fuel consumption. The pump’s precise hydraulic design, smooth flow paths, and high hydraulic efficiency reduce overall energy consumption by 10%-20% compared to traditional fire pump systems, achieving energy-saving operation while ensuring fire safety. Furthermore, the system operates with low noise and vibration, minimizing environmental impact, in line with the development trend of modern green firefighting equipment. This equipment is widely used in industrial plants, petrochemical bases, urban water supply systems, firefighting vessels, and high-rise buildings, requiring highly reliable water supply. It is particularly suitable for projects that rely heavily on electricity but require independent emergency water supply capabilities. Its modular design facilitates on-site installation. Factory-installed and commissioned, it can be put into operation directly, reducing construction timelines and improving project efficiency. Whether used as a backup pump unit in conventional firefighting systems or as an independent fire water supply system in remote locations, diesel fire pump systems demonstrate exceptional stability and flexibility. In summary, with its powerful power performance, reliable self-priming function, excellent energy-saving design, and comprehensive safety features, diesel fire pump systems have become an indispensable component of modern firefighting projects. It’s more than just an emergency water supply device; it’s a highly intelligent system integrating mechanical, electrical, and automatic control functions. It can ensure the continuity and safety of fire water supply in a variety of complex environments, providing a solid fire protection solution for industrial facilities, urban buildings, and public infrastructure. In the future, with the continuous development of intelligent and green energy-saving technologies, diesel fire pump systems will continue to be optimized and upgraded, further enhancing performance, control, and environmental protection, providing higher-standard, more efficient solutions for global fire safety.

管道泵(不锈钢304316L).jpg)