Diesel engine fire pump set is an advanced fire fighting equipment

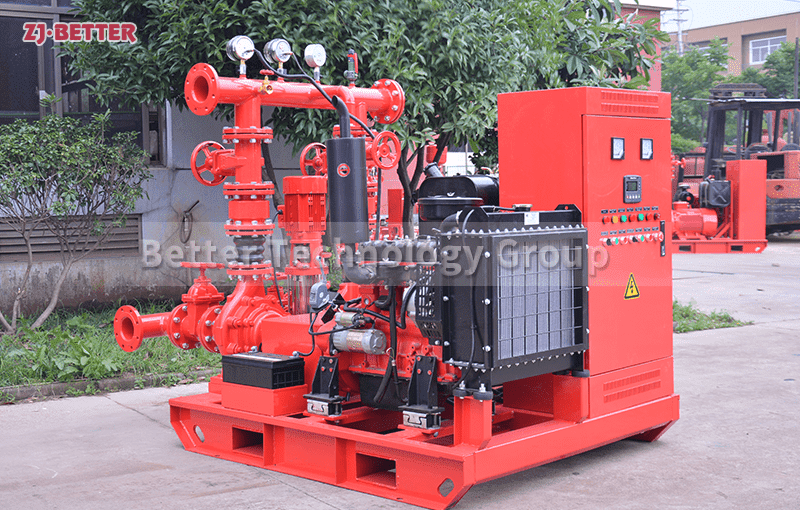

As a fixed fire-fighting equipment, the diesel engine fire-fighting pump set has been widely used in fire-fighting diversion, especially for fire-fighting water supply in unexpected situations such as no power supply or abnormal power supply (mains power). The water pumps in the unit are horizontal single-stage and multi-stage fire pumps produced by our company, which are mainly composed of diesel engines, fire pumps, coupling devices, fuel tanks, radiators, battery packs, intelligent automatic control panels, etc.

The diesel engine equipped with the equipment is made of domestic or imported products. It has the characteristics of good starting characteristics, strong overload capacity, compact structure, convenient maintenance, simple use, and high degree of automation. It is an advanced and reliable fire-fighting equipment.

Diesel engine fire pumps are aimed at fire water supply for high-flow and high-lift occasions, and the diesel engine has good start-up characteristics, fast start-up speed, strong overload capacity, and does not need to run and stand by all the time, which is energy-saving and efficient. Diesel engine fire pumps have complete performance and a wide range of models. They can be used in single-stage single-suction pumps, multi-stage single-suction pumps, self-priming pumps, long-axis pumps, etc., and can also be used in combination and in parallel, with a wide range of flow and pressure. Diesel engine fire pumps are widely used for fire water supply in warehouses, docks, airports, petrochemical, power plants and other industrial and mining enterprises. Larger flow and head. The temperature of the conveying medium can reach 80°C.