Fire pump maintenance essential skills

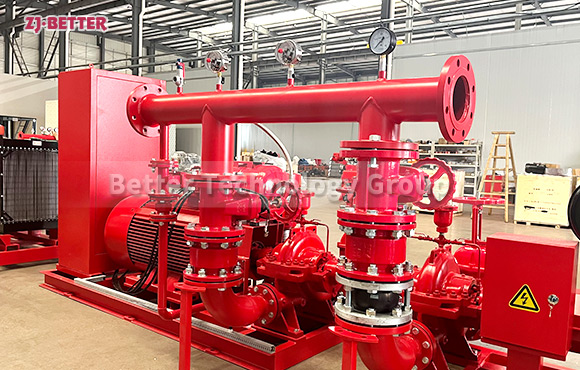

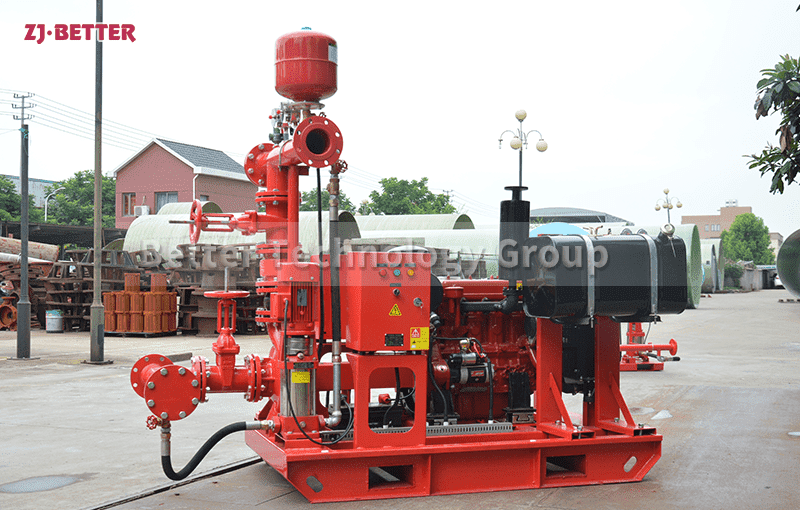

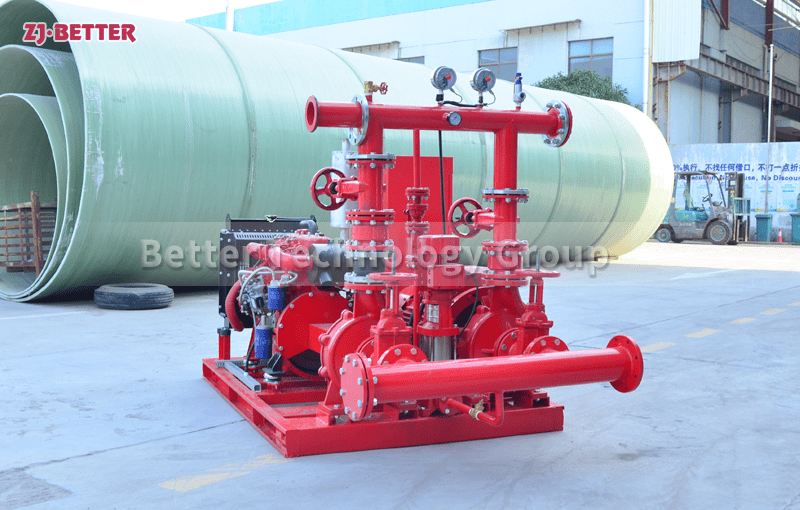

1. Knowledge of Fire Pump Design and Components: Fire pumps are complex pieces of machinery, and technicians must be familiar with its components, including the electric motor, reservoir, impeller, and check valves.

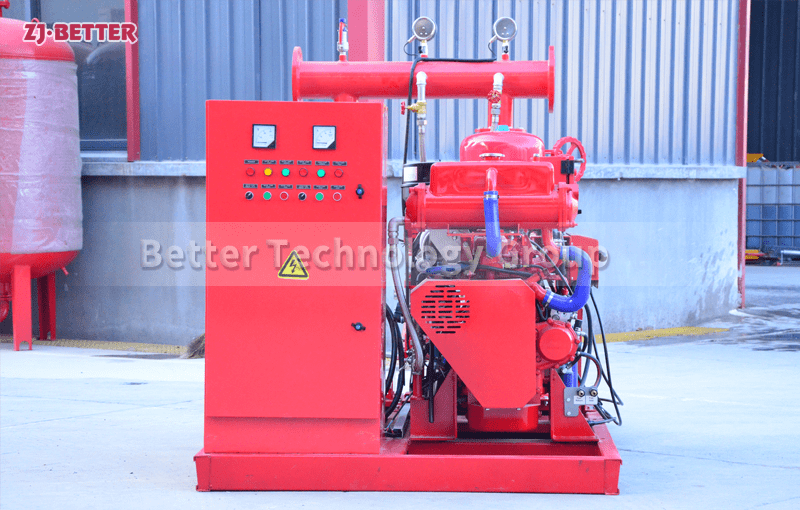

2. Electrical Troubleshooting: Electric motor control centers, circuit breakers, and other electrical components must be understood by technicians in order to properly maintain fire pumps.

3. Instructions for Proper Maintenance: Technicians must be able to read and understand manufacturer’s instructions for inspection and required maintenance, such as oil and filter changes.

4. Record Keeping: Accurate records of maintenance must be kept in order to ensure that fire pumps are in peak working condition.

5. Diagnose and Repair of Pump Malfunctions: Technicians must have the ability to diagnose and fix common pump problems such as bearing wear, corrosion, and bearing failure.

6. Troubleshoot Accessories and Peripherals: Technicians should be familiar with fire pump accessories such as pressure switches, gauges, and houseline piping.

7. Handle Power Sources: Technicians must have the knowledge to recognize safe levels of power sources, such as AC or DC, to ensure fire pump operations.

8. Pressure Testing: Technicians must understand and follow safety procedures when pressure testing fire pumps and their related houselines.

1. Knowledge of Fire Pump Design and Components: Fire pumps are complex pieces of machinery, and technicians must be familiar with its components, including the electric motor, reservoir, impeller, and check valves.

2. Electrical Troubleshooting: Electric motor control centers, circuit breakers, and other electrical components must be understood by technicians in order to properly maintain fire pumps.

3. Instructions for Proper Maintenance: Technicians must be able to read and understand manufacturer’s instructions for inspection and required maintenance, such as oil and filter changes.

4. Record Keeping: Accurate records of maintenance must be kept in order to ensure that fire pumps are in peak working condition.

5. Diagnose and Repair of Pump Malfunctions: Technicians must have the ability to diagnose and fix common pump problems such as bearing wear, corrosion, and bearing failure.

6. Troubleshoot Accessories and Peripherals: Technicians should be familiar with fire pump accessories such as pressure switches, gauges, and houseline piping.

7. Handle Power Sources: Technicians must have the knowledge to recognize safe levels of power sources, such as AC or DC, to ensure fire pump operations.

8. Pressure Testing: Technicians must understand and follow safety procedures when pressure testing fire pumps and their related houselines.