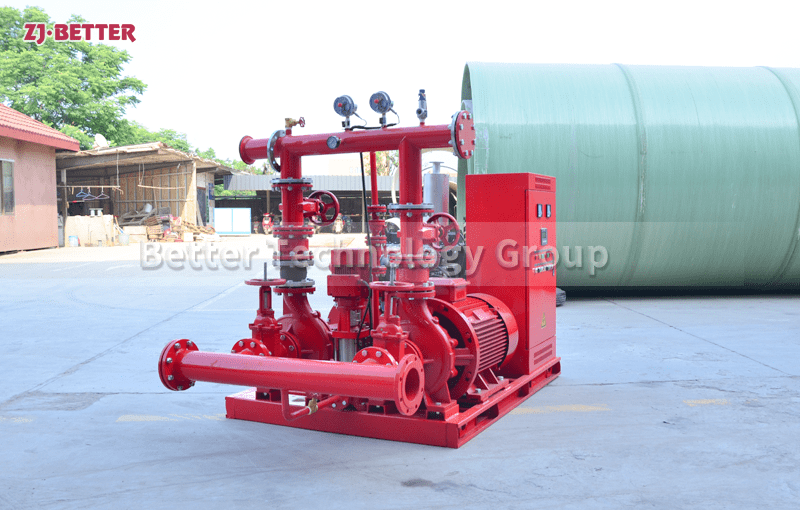

Electric fire pumps are widely used in fire departments

As the name implies, the fire pump is a pump used in fire protection. The fire pump is an imported product. It is divided into different types according to different classification methods. It is fully sealed, leak-free, and corrosion-resistant. It is widely used in environmental protection, water treatment, fire protection, etc. The department is used to pump various liquids, and it is an ideal pump and fire protection system for creating a leak-free, pollution-free civilized workshop and civilized factory. The pump types are similar, but the head and flow are different.

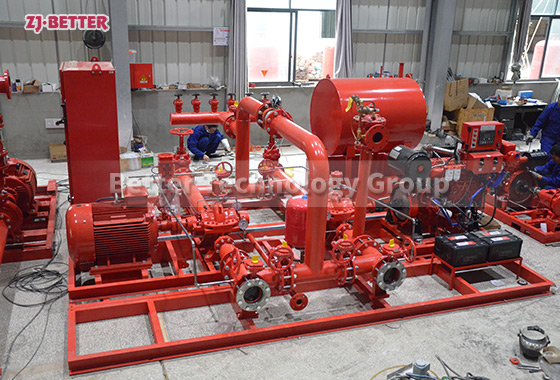

The inspection work of the electric fire pump is mainly composed of various components, such as motor, pump base, coupling, bearing, shaft and sealing device, impeller, etc. The corresponding inspection and maintenance records should be done well, and the records are for better use of fire protection pumps. The pump is also a good basis for finding sudden faults. The long-term use of the motor fire pump is more stable. For the maintenance of the fire pump, you can communicate with the fire pump manufacturer more, so that the fault can be solved in time.