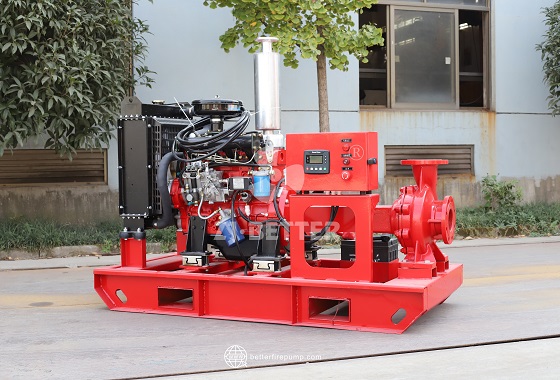

Next-Generation Energy-Efficient Diesel Fire Pump: The Perfect Combination of Reliability and Performance

This energy-efficient, next-generation diesel fire pump features powerful power, low fuel consumption, and a fully automatic control system, ensuring a stable and reliable fire water supply during power outages or emergencies. Its high head, high flow rate, intelligent monitoring panel, low-noise operation, and multiple safety features make it an ideal firefighting option for high-rise buildings, factories, oil depots, docks, and other locations, providing safe and efficient firefighting.

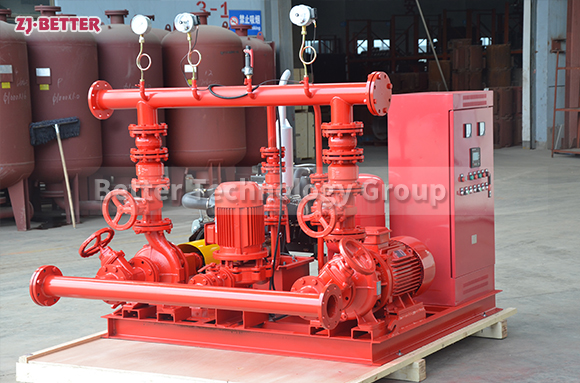

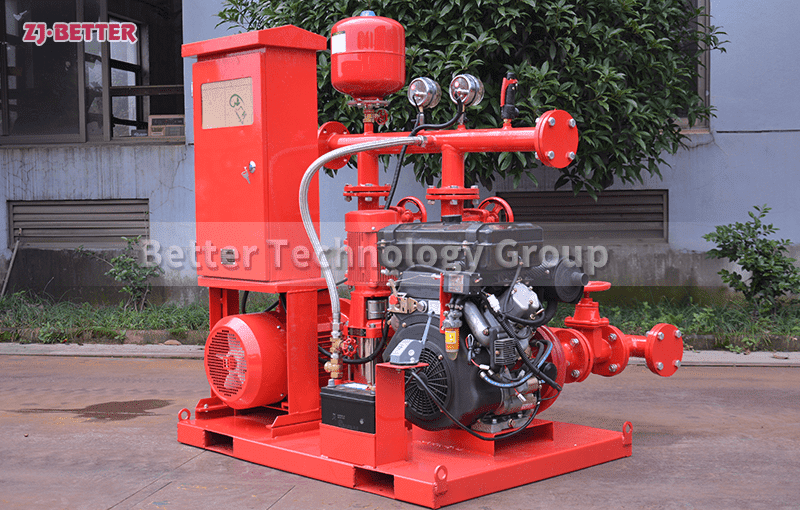

The energy-efficient, high-efficiency, new-generation diesel fire pump, with its superior performance, reliable structural design, and advanced control technology, is becoming an indispensable core power source in modern firefighting systems. Designed specifically to meet the emergency water supply needs of fires in diverse and complex environments, these fire pumps are capable of maintaining stable operation during power outages, extreme temperatures, in remote areas, or even in large buildings, providing continuous, strong water pressure support for fire safety. They not only represent the trend toward energy-saving, intelligent, and modular firefighting equipment, but also embody the perfect blend of high efficiency and reliability. Diesel fire pumps play a critical role in firefighting systems, especially in locations with unstable power supplies or where independent operation is required. Their high reliability is particularly important. This new-generation diesel fire pump utilizes an internationally advanced energy-saving power system, with a perfectly matched engine and pump body. This ensures high output power while significantly reducing fuel consumption, achieving a higher energy efficiency ratio. By optimizing the combustion system and mechanical transmission structure, the engine’s fuel efficiency is significantly improved, saving 10% to 15% fuel per operating time. This not only reduces operating costs but also lowers environmental emissions, meeting the requirements of modern green and energy-saving industry. Its high-efficiency centrifugal pump design ensures stable performance even under high head and flow conditions, resulting in smooth water flow and minimal pressure fluctuations, making it suitable for a wide range of fire protection pipe network systems. Structurally, this new generation diesel fire pump features a modular design, with the base, engine, pump, and control system integrated into one unit, greatly simplifying installation and maintenance. The pump body is constructed of high-strength cast iron or stainless steel, offering exceptional corrosion and impact resistance, enabling long-term operation in harsh environments such as humidity, heat, and dust. The transmission system utilizes a flexible coupling, ensuring precise coaxiality between the engine and pump body, resulting in lower operating noise, minimal mechanical wear, and significantly extending the equipment’s service life. The control system is a key highlight of this new generation diesel fire pump. The fully automatic intelligent control panel, equipped with a multi-function display, provides real-time monitoring of key data such as engine speed, water pressure, water temperature, oil pressure, fuel level, and operating time. If the system detects a failure in the electric pump or a drop in pipe network pressure, the diesel pump automatically activates without manual intervention, providing a truly automatic backup water supply. The system also features both manual and automatic control modes and a remote monitoring interface, enabling networking with the fire department for remote start-up and data upload, meeting the integration requirements of smart firefighting systems. To ensure immediate response in the event of a fire, the starting system design of this new generation diesel fire pump is crucial. It utilizes a dual-battery parallel starting method, ensuring rapid engine start-up even in low temperatures or with degraded battery performance, with a start-up success rate exceeding 99%. A manual emergency start mechanism ensures pump operation even under extreme conditions. The lubrication and cooling system design also demonstrates its advanced design. The engine utilizes forced circulation lubrication and a high-efficiency air or water cooling system, maintaining stable temperatures during prolonged, high-load operation. This effectively prevents mechanical wear caused by overheating and poor lubrication, ensuring reliable, continuous operation. To enhance safety, the pump is equipped with multiple protection devices, including low oil pressure protection, high water temperature protection, overspeed protection, and low fuel alarms. In the event of an abnormality, the system will automatically sound an alarm or shut down the unit, minimizing equipment damage and ensuring on-site safety. In terms of performance, this diesel fire pump offers excellent output capacity and operational stability. With a maximum flow rate of hundreds of cubic meters per hour and a lift exceeding 100 meters, the new generation diesel fire pump can meet the fire water supply needs of high-rise buildings, industrial plants, petrochemical plants, docks, warehouses, and other locations. Its powerful power output and rapid response time, starting up and reaching rated speed in just over ten seconds, ensures rapid and sufficient water supply at the initial stages of a fire, buying valuable time for firefighting. Furthermore, the equipment has undergone precise dynamic balancing and noise optimization, resulting in minimal vibration and noise levels below national standards, enhancing operator comfort and extending the life of system components. To adapt to diverse global climates, the new generation diesel fire pump can be configured with various levels of protection, including dustproof, rainproof, explosion-proof, or containerized enclosed structures. The containerized design is particularly suitable for outdoor or mobile firefighting systems. Equipped with internal sound insulation, lighting, and ventilation, it protects the equipment from environmental influences while facilitating transportation and rapid deployment. Regarding energy management, the new generation diesel fire pump utilizes a precise electronic speed control system to control fuel injection volume, automatically adjusting output power according to load changes, ensuring optimal engine operation and significantly reducing fuel consumption and mechanical wear. Furthermore, the use of a new shock-absorbing base and silencer exhaust system effectively reduces vibration and noise pollution during operation, making it more suitable for use in urban fire protection systems. Notably, the equipment is manufactured in strict compliance with international fire pump standards and quality control systems. Each unit undergoes pressure testing, performance testing, startup testing, and long-term operation testing before shipment, ensuring stable and reliable operation under all conditions. Maintenance is also extremely convenient, with all vulnerable parts featuring a modular design that allows for quick assembly and replacement, reducing ongoing maintenance costs. Furthermore, users can choose from options such as dual-pump systems, parallel control, automatic switching, and remote alarms to achieve more flexible firefighting configurations based on application requirements. Overall, this energy-efficient, new-generation diesel fire pump, with its powerful power, high energy efficiency, automatic control, and reliable durability, provides safe and stable fire water supply for various buildings and industrial sites. It not only represents the development direction of modern firefighting technology but also provides users with an economical, efficient, and environmentally friendly emergency water supply solution. This pump unit has demonstrated unparalleled performance advantages and long-term reliability in applications such as urban firefighting, industrial protection, ports and terminals, oil and gas storage and transportation, power facilities, and tunnel engineering. As the concepts of smart firefighting and green energy conservation continue to deepen, the new generation of diesel fire pumps will continue to play a vital role in the field of safety and protection, providing more intelligent and sustainable power support for global firefighting systems.