Versatile Fire Pump System: Meeting the Fire Protection Needs of Industrial, Commercial, and High-Rise Buildings

Our versatile fire pump system is designed to meet the diverse and complex fire protection requirements of industrial, commercial, and high-rise buildings. Whether it’s an oil refinery, a commercial complex, or a modern high-rise residential tower, our fire pump system delivers robust hydraulic support, ensuring that fire suppression systems can quickly respond and perform at their best in the event of a fire.

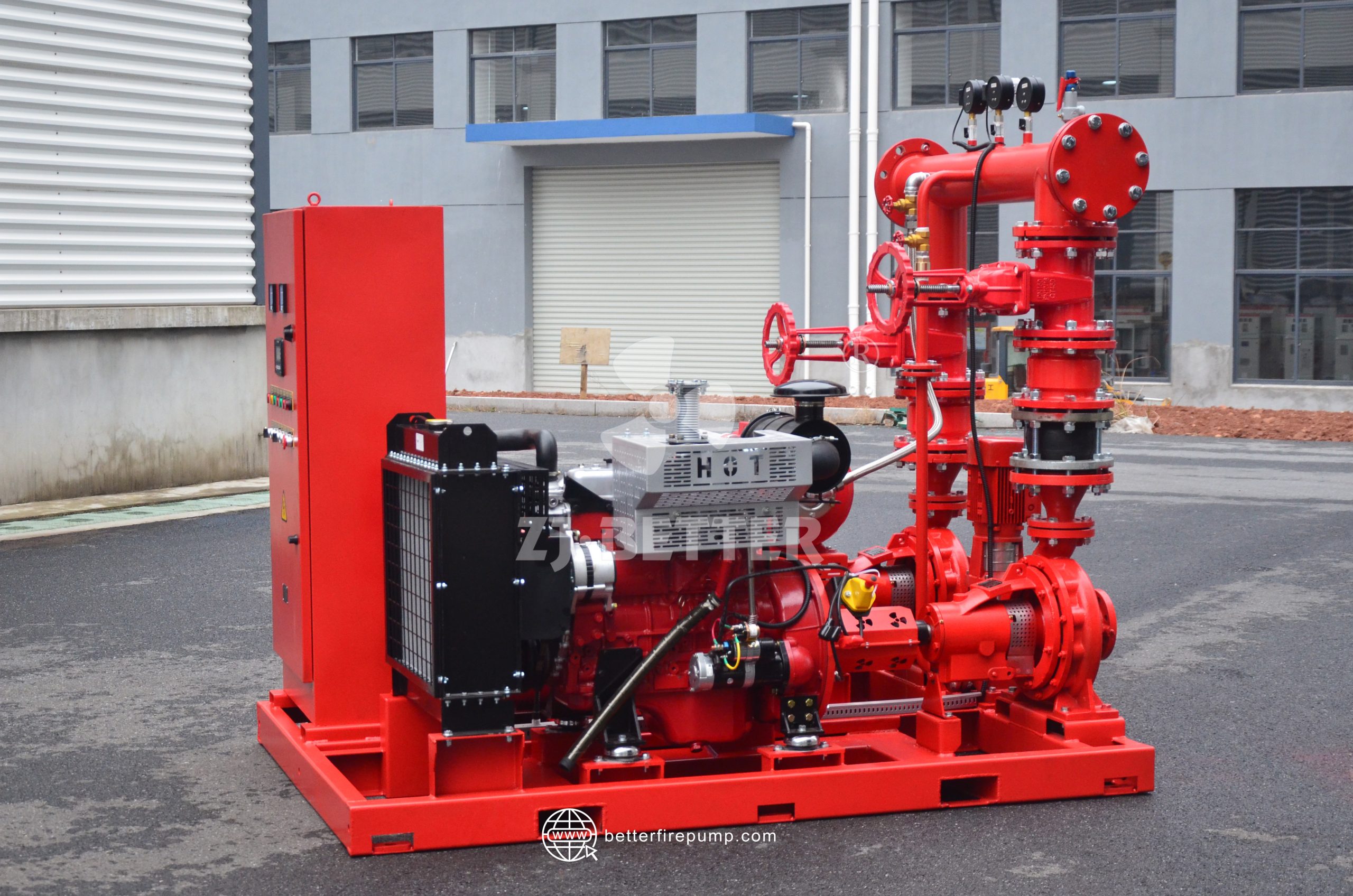

This fire pump system features dual power configurations with both diesel engines and electric motors, making it capable of handling emergency situations such as power outages. The system is equipped with a smart control panel, enabling features like automatic start/stop, fault alarms, and system self-checks, ensuring long-term stability and reliability of the equipment. No matter how complex or harsh the environment, our fire pump system provides a stable, efficient, and continuous water supply.

Additionally, the system’s compact design makes installation and maintenance easy and convenient, accommodating various space requirements. Fully compliant with international fire protection standards, our fire pump system is the ideal solution for fire safety in all types of building projects.

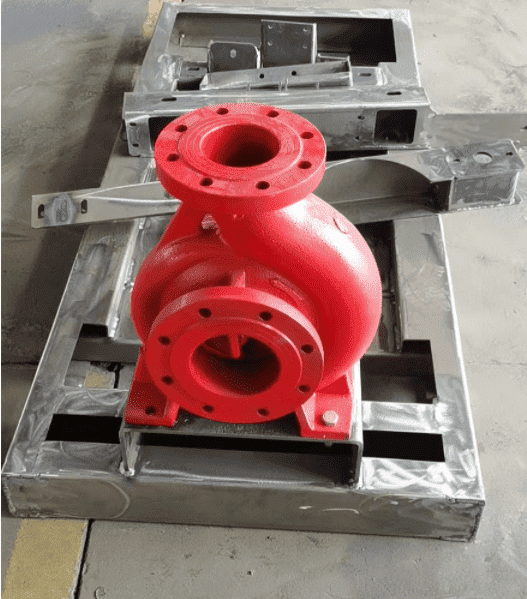

We specialize in providing efficient and reliable fire pump solutions, dedicated to delivering high-quality fire protection equipment to customers worldwide. Our fire pump systems are widely used in industrial, commercial, residential, and high-rise building projects, ensuring rapid and effective water supply in case of fire, safeguarding life and property. By integrating modern technology and precision manufacturing processes, our products excel in performance, stability, and durability.

Our fire pump systems are versatile, offering various power configurations with both electric motors and diesel engines to meet different application needs. Whether for routine water supply, fire-fighting operations, or emergency backup, the system ensures efficient operation. Every unit undergoes rigorous quality testing before delivery, conforming to international fire protection standards, providing customers with the highest level of fire safety assurance.

In addition, we offer customized services to design fire pump solutions tailored to meet specific requirements and environmental conditions. Our technical and after-sales support teams provide comprehensive assistance to ensure every detail meets the highest standards.