High-Flow Diesel Fire Pump Package for Demanding Sprinkler and Hydrant Applications

The high-flow diesel fire pump unit is a high-performance water supply equipment designed specifically for large-scale fire protection projects. It features strong power, high flow output, independent operation capability, and multiple intelligent protections. It is suitable for factories, warehouses, chemical plant areas, and environments without power supply, providing a continuous and stable fire water supply guarantee for sprinkler and fire hydrant systems.

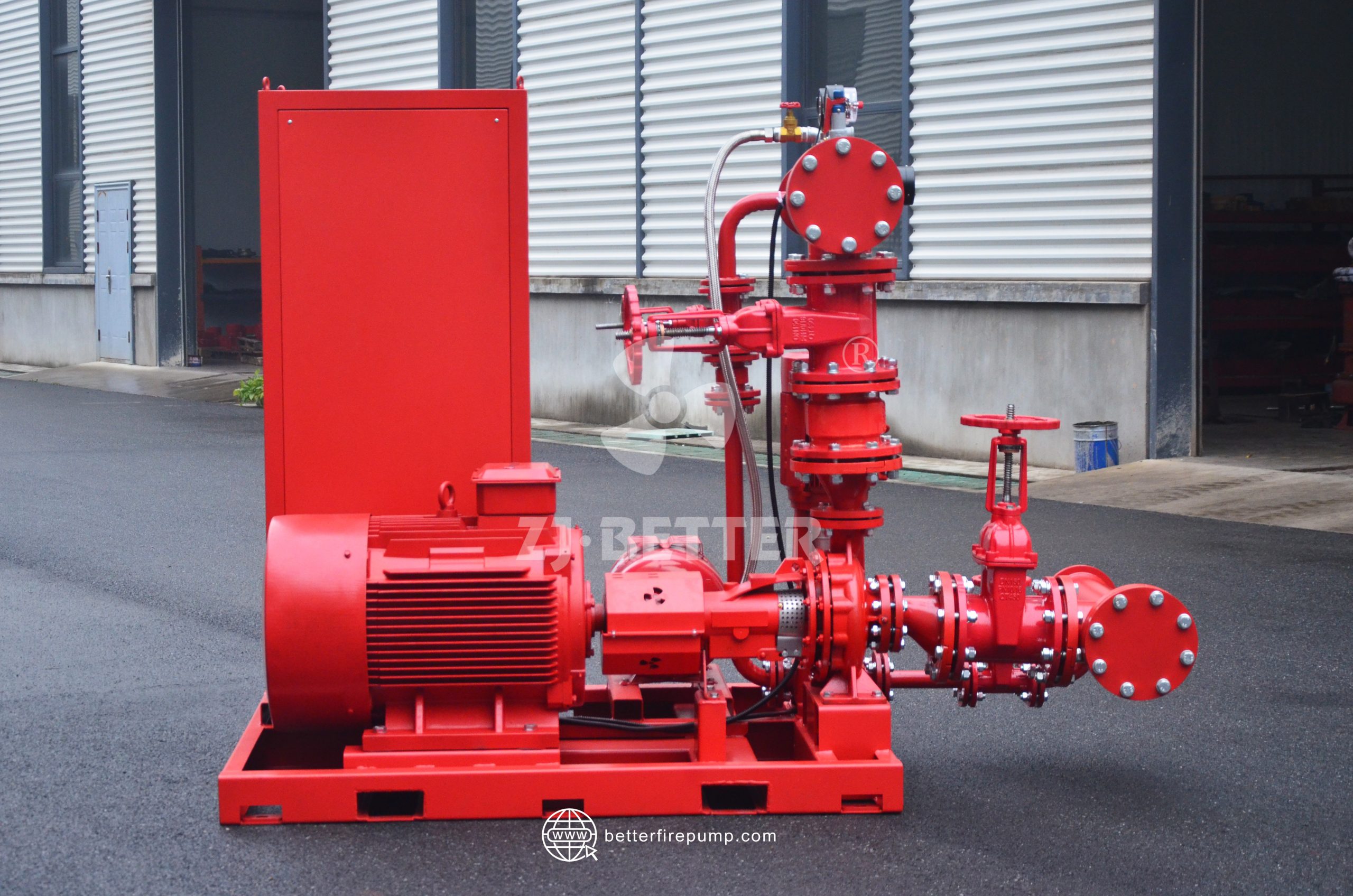

High-flow diesel fire pump units, as an irreplaceable core emergency water supply equipment in modern fire protection engineering, rely on a powerful diesel power system, optimized hydraulic structure, and fully automatic control technology to provide continuous and stable high-intensity water supply for scenarios such as sprinkler systems, fire hydrant systems, large water cannons, and elevated fire water tank replenishment. This equipment is specifically designed for large industrial parks, logistics and warehousing centers, ports, chemical plant areas, urban complexes, and environments without a stable power supply. It can maintain reliable operation under extreme conditions such as power outages, high temperatures from fires, and severe damage. Its independent power source and superior output performance ensure that the fire protection system has a powerful fire-fighting water volume support at critical moments. The complete high-flow diesel fire pump unit consists of a diesel engine, centrifugal fire pump, cooling system, fuel system, exhaust system, dedicated coupling, base, intelligent electrical control cabinet, and piping components. The diesel engine, as the core power source, uses a large-displacement industrial-grade engine with strong explosive power and stable torque output. It can quickly complete high-speed startup and drive the pump to rated speed, providing a large flow of water in the first few seconds of a fire. The centrifugal pump section is based on advanced hydraulic design, optimizing the impeller curve, flow channel cross-section, and pump body structure to maintain high efficiency and stable head output under high flow conditions. This enables it to withstand harsh operating conditions such as long-distance water transmission, high-rise building water supply, and maintaining pressure in complex pipe networks. The equipment’s operational stability stems from its comprehensive intelligent control system. The electrical control cabinet supports multiple modes including automatic start, delayed start, manual debugging, linkage control, and remote signal output. When the fire protection system issues a linkage signal, such as a pressure drop, water flow indicator activation, or fire detection system triggering, the electrical control system immediately executes the start-up procedure. The diesel engine enters working condition within seconds, and the pump body quickly establishes sufficient water pressure to ensure a rapid response in the initial stages of a fire. The electrical control system also features protection against low oil pressure, high temperature, abnormal speed, excessively high water temperature, and overspeed. Any abnormality will automatically trigger a shutdown or alarm operation to ensure the equipment operates within safe limits. Furthermore, the cooling system of the high-flow diesel fire pump unit adopts water cooling, air cooling, or a combination of cooling methods, combined with a large-area radiator and high-temperature resistant coolant, enabling the equipment to maintain a stable temperature during long-term high-load operation and preventing performance degradation or damage due to overheating. The exhaust system adopts a heat-insulated pipe structure and is equipped with a silencer to reduce operating noise and prevent exhaust temperature from affecting the surrounding environment. The fuel system provides a large-capacity fuel tank and is equipped with fuel level monitoring, fuel line filtration, and fuel pump pressurization functions to ensure a continuous and stable fuel supply during long-term operation, thereby achieving uninterrupted fire-fighting water supply. The advantages of this equipment in engineering applications are extremely prominent. First, its high-flow output capacity enables it to meet the needs of high-intensity fire-fighting scenarios such as large-area fires, warehouse fires, high-stack fires, and oil tank fires, playing a key role when a large amount of water is needed to quickly cover the fire source. For example, in chemical facilities, sprinkler rings, water curtain systems, and water cannon systems require a large amount of water supply instantly; the diesel fire pump unit can provide high flow and high pressure, allowing the fire-fighting system to maintain a continuous impact force. Secondly, its independent power system offers the advantage of not relying on a power supply, allowing it to operate normally even when a fire causes a power grid failure, indoor power distribution is damaged, or high temperatures affect power supply. This is especially important during extreme disasters such as earthquakes, torrential rains, and typhoons, ensuring the fire protection system continues to operate unaffected by external environmental factors. Thirdly, the equipment has the capability for long-term continuous operation, making it suitable for scenarios requiring extended firefighting time. In emergencies, it can provide uninterrupted water supply for several hours, ensuring sufficient water support for large fires, a critical performance feature in large warehouses, refineries, and port storage yards. Fourthly, the unit’s structure employs a high-strength welded base and seismic design, adapting to complex operating conditions such as frequent vibrations, heavy pressure, and outdoor climate changes. It also features anti-corrosion coatings and weather-resistant materials to extend its service life in humid, high-salt-spray, and dusty environments. Fifthly, installation and maintenance are highly convenient. The unit has an integrated structure, simplifying transportation, hoisting, and on-site connection. Operation is achieved simply by connecting the inlet and outlet pipes, exhaust system, and electrical control lines. Maintenance requires only checking the engine oil, filter, coolant, water pump shaft seal, and indicator lights on the electrical control system, eliminating the need for frequent disassembly and reducing operating costs. The high-flow diesel fire pump unit also boasts flexible adaptability, enabling it to integrate with main pumps, pressure-stabilizing pumps, fire monitoring systems, fire alarm control panels, and remote monitoring centers to achieve intelligent operation of the entire fire protection system. Its standardized signal interface allows for use in new construction projects as well as the upgrading and renovation of existing fire protection systems, achieving systematic, automated, and highly secure fire water supply. In various large-scale fire safety systems, the high-flow diesel fire pump unit, with its strong power output, high-flow water supply, reliable independent operation capability, and multiple protection functions, has become a key core fire protection equipment and a crucial safety barrier for various high-risk areas and large-scale projects. Whether in emergency situations or in long-term standby mode, this equipment provides stable, efficient, and powerful water supply support, offering vital protection for life and property.