How to Set Up a Fire Pump Alarm System

Learn how to properly set up a fire pump alarm system to detect failures, ensure safety, and comply with NFPA 20.

A fire pump alarm system plays a crucial role in detecting malfunctions and ensuring rapid response. Here’s how to set it up properly:

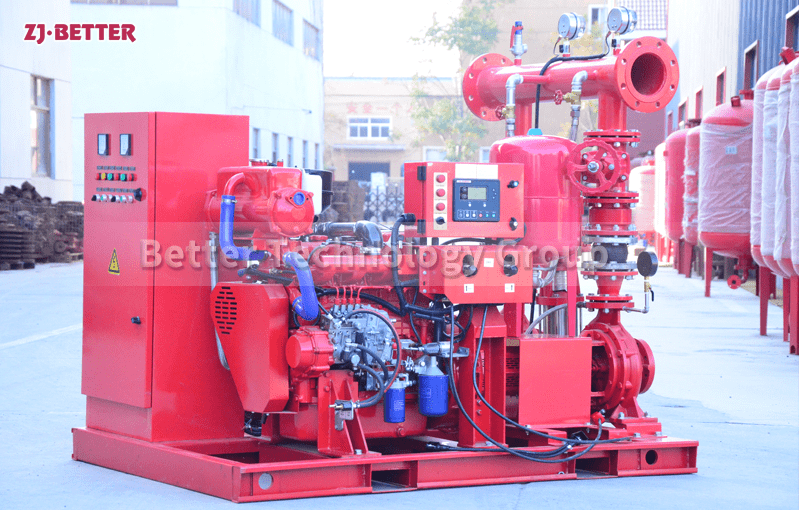

1. Choose the Right Fire Pump Controller

-

Fire pump controllers come with built-in alarms for pressure drops, motor failures, and power loss.

-

Ensure NFPA 20 compliance.

2. Install Alarm Sensors and Devices

-

Pressure switches to monitor water pressure.

-

Flow switches to detect water movement.

-

Temperature sensors to monitor overheating.

3. Connect to a Central Monitoring System

-

Integrate with a fire alarm panel or building management system (BMS) for real-time alerts.

4. Conduct Routine Testing

-

Test alarm functions monthly to verify performance.

-

Keep detailed logs for compliance and maintenance.

A properly installed and tested fire pump alarm system enhances fire protection reliability and ensures compliance with fire safety regulations.