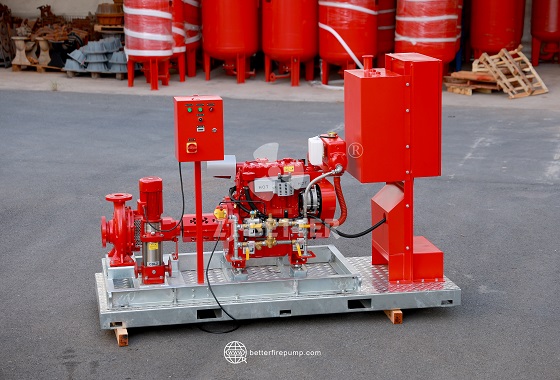

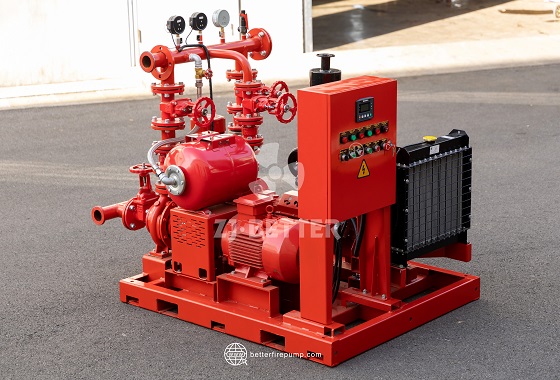

Fire pump set manufactured by Better Technology CO., LTD. In accordance with the Chinese national standard GB27898.5-2011 fixed fire water supply equipment part 5 “fire double power water supply equipment” hereinafter referred to as “packaged fire pump”, “ Fire Pump Set” or “fire pump packages” and National Fire Protection Association’s NFPA20 “Standard for the Installation of Stationary Pumps for Fire Protection”(2016). and meet the latest Chinese national standard CCCF certification requirements and obtain a certificate. Fire pump package is one of the reliable products in fire water supply equipment.

The minimum fire rated working pressure of fire pump package is 0.3MPa, and the minimum fire rated working flow is 2L/S. The fire pump package includes at least two types of motor pump sets, engine pump sets, jockey pump sets, diaphragm pressure tanks, pipes, valves, electrical control systems, control sensors and other related accessories driven by the power source. Fire water supply equipment continuously supplies water to the fire pipe network. The reasonable layout, the firm installation, the reliable connection, the compact and tidy structure, and convenient for maintenance and overhaul.

-2.jpg)