Functional use of diesel engine fire pump

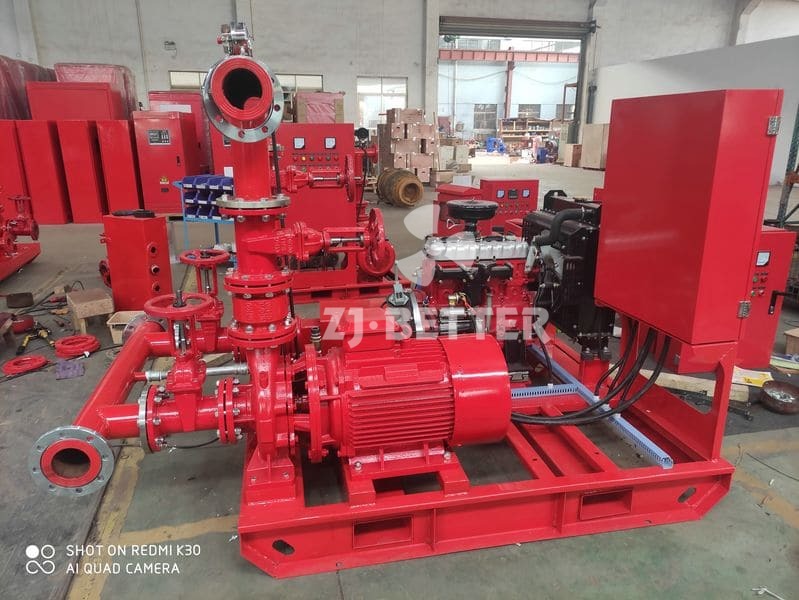

Diesel engine fire pumps are often used for emergency water supply in high-rise buildings, water companies, steel plants, wineries, chemical plants, hotels, hospitals, and other large-scale projects. Diesel engine fire pump is suitable for unattended emergency water supply system. The product has the characteristics of advanced technology, high degree of automation, superior performance, complete protection functions, reasonable structure, simple installation, and high cost performance. net pressure.

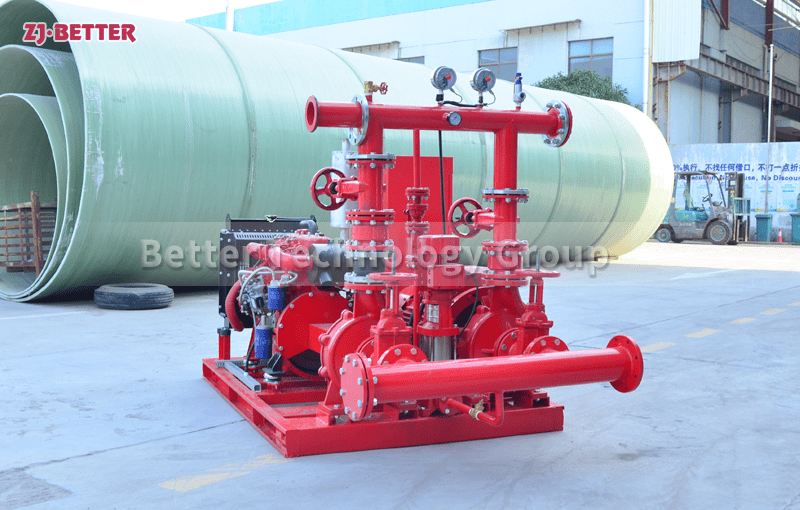

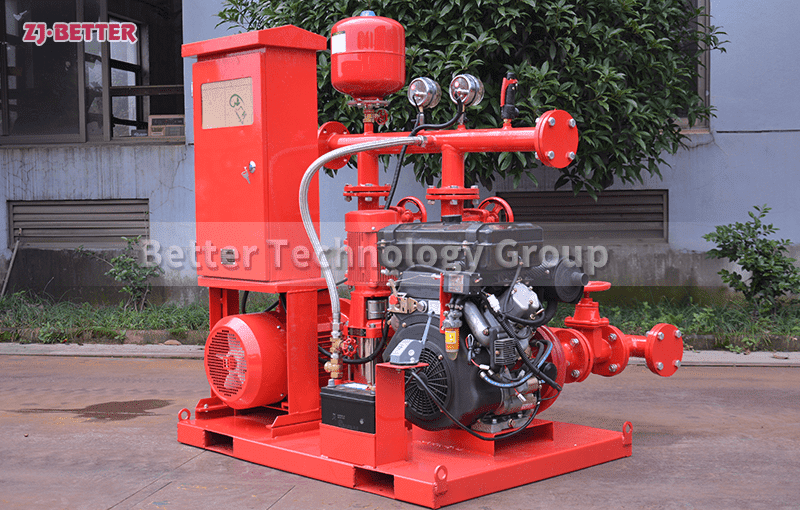

The diesel engine fire pump has the characteristics of good starting characteristics, strong overload capacity, compact and reasonable structure, convenient maintenance, simple and reliable use, etc. The unit is equipped with protection functions such as overspeed, low oil pressure, three start failures, high water temperature, low oil level, and low battery voltage. Diesel engine fire pump is composed of diesel engine, chassis, cooling water tank and fan, high elastic coupling, water pump, diesel tank and control panel and other equipment. The diesel engine fire pump is directly connected with the diesel engine through a highly elastic coupling or a diaphragm coupling, and is installed on a common channel steel chassis.