Fire pump equipment used in different fields

Fire pumps have a wide range of uses. In addition to providing water for fire-fighting piping systems, they can also be used for industrial water delivery. Fire pumps can also be used for water supply and drainage systems in cities. There are other relatively long-distance water delivery tasks, such as heating boilers, hot and cold water circulation pressurization of bathroom boilers, etc., which can all be completed by means of fire pump systems.

Fire pumps used in different fields have different professional characteristics. For example, fire pumps in the general sense are installed on professional fire trucks or other special fire-fighting facilities, and are used to transport water and foam solutions for fire-fighting Pump.

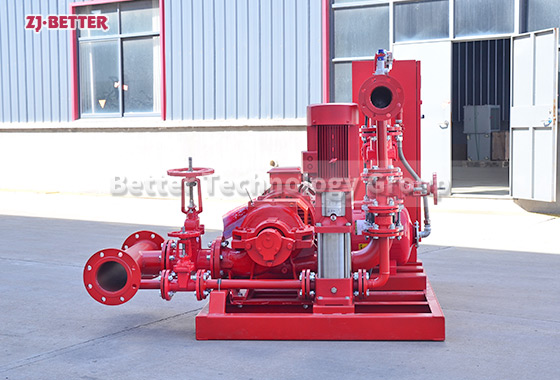

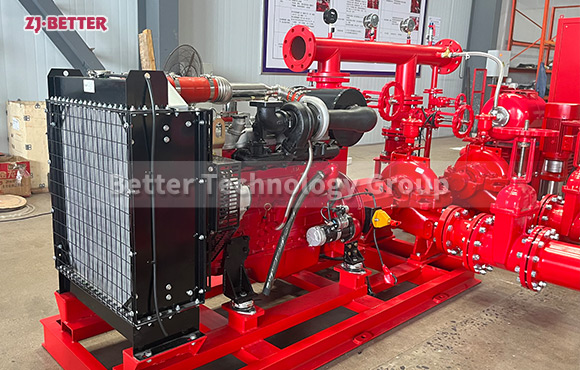

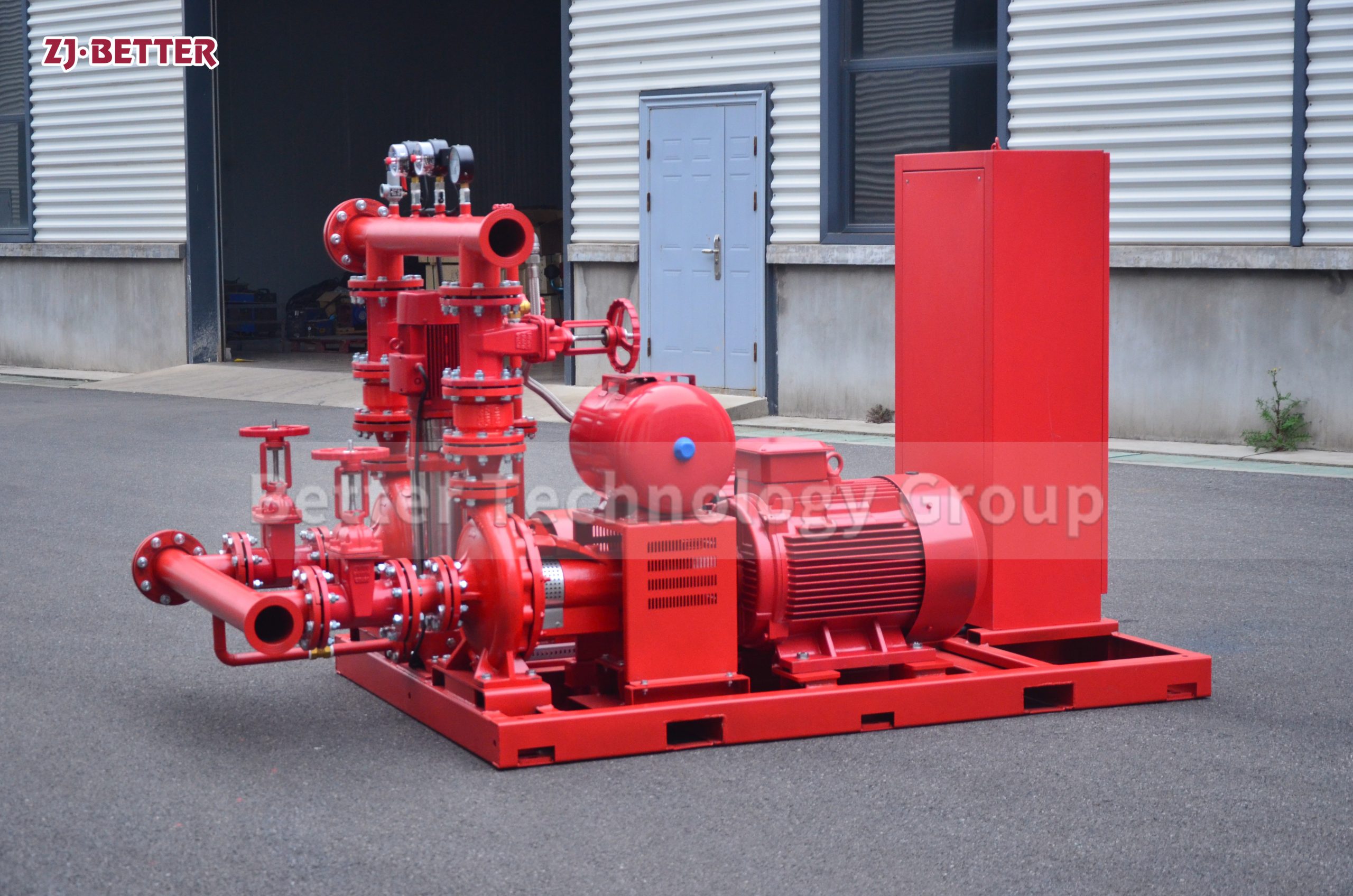

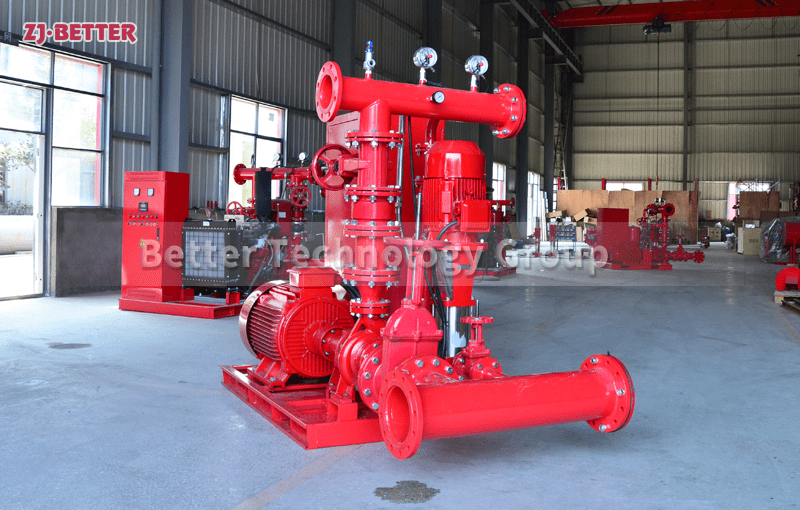

The fire pump set with power source is mainly composed of four main parts, a set of fire pumps, a power source that provides power for the fire pump set, a control cabinet that controls the fire pump set, and some other auxiliary devices. There are also many categories of fire pump sets with different professional characteristics. For example, the ordinary fire pump group mainly composed of ordinary fire pumps, the water supply fire pump group mainly composed of water supply fire pumps, the deep well fire pump group composed of deep well fire pumps and the submersible fire pump group composed of submersible fire pumps, etc.