High Pressure and Flow Capacity Combined: Introduction to Diesel-Electric Combined Drive Fire Pump

Product features and performance advantages of this diesel electric combined drive fire pump. The equipment combines electric motor and diesel engine dual power system to ensure continuous water supply even under unexpected circumstances such as power outages, enhancing the reliability of the fire fighting system. The product has high pressure and high flow output, excellent hydraulic performance, intelligent control, compact structure for easy installation, adaptable to a variety of harsh environments, and support for customization, in line with a number of international fire standards. The overall design is geared towards demanding scenarios, such as high-rise buildings, petrochemical parks, underground facilities, etc., and is an ideal solution to meet the challenges of modern fire protection.

As urban infrastructures grow in scale and complexity, so too do the demands placed on fire protection systems. Modern buildings, industrial facilities, petrochemical plants, and underground installations require firefighting pumps capable of delivering both high pressure and large volumes of water, consistently and reliably. The Diesel-Electric Combined Drive Fire Pump addresses these requirements with a dual-power design that ensures continuous operation even in the event of a power outage—making it an ideal solution for critical safety infrastructure.

1. Dual Power System for Uninterrupted Operation

This pump integrates an electric motor for primary power and a diesel engine as a fully automatic backup. When grid power is lost or unstable, the system seamlessly switches to diesel operation without interrupting water delivery, ensuring continuous fire protection at all times.

2. Superior Hydraulic Performance

Designed with optimized flow channels and a high-efficiency impeller, this unit delivers a high head and strong water flow, making it ideal for multi-story buildings, long-distance pipe networks, and complex industrial environments. Energy loss is minimized, and operational efficiency is maximized.

3. Intelligent Automated Control

Equipped with an advanced control panel featuring PLC technology, the system offers automatic start/stop, real-time monitoring, alarm notifications, and remote operation capabilities. A touchscreen interface enables users to manage parameters and access operation logs with ease.

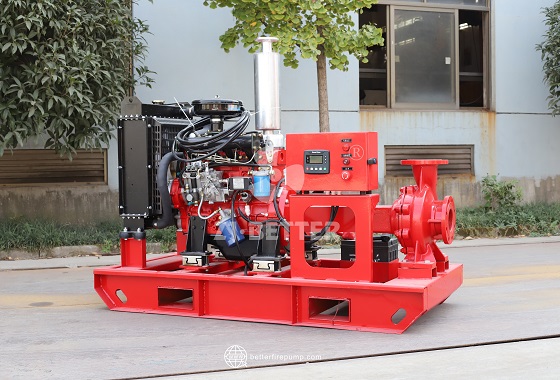

4. Compact and Integrated Skid-Mounted Structure

All core components—electric pump, diesel pump, controller—are mounted on a single steel base. This integrated design simplifies transportation and installation while improving overall mechanical stability. Maintenance is more accessible, and space utilization is optimized.

5. Rugged and Reliable in Harsh Environments

Built with corrosion-resistant, high-strength materials, the pump is engineered for long service life and performance stability under extreme temperatures, humidity, and airborne particulates. It is suitable for use in demanding applications like industrial zones and outdoor installations.

6. Standards-Compliant and Fully Customizable

The system conforms to international firefighting standards, including GB6245 and NFPA 20. Custom configurations are available to meet specific site conditions, including power rating, flow rate, pressure head, pipe diameter, and more.