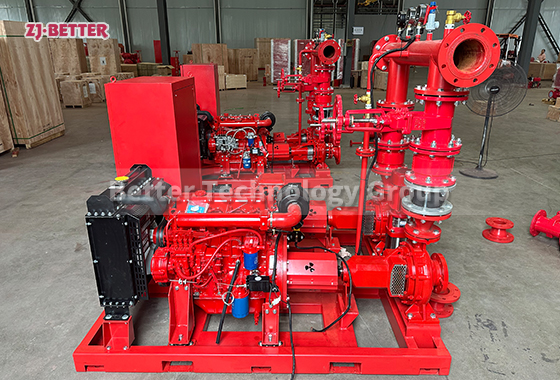

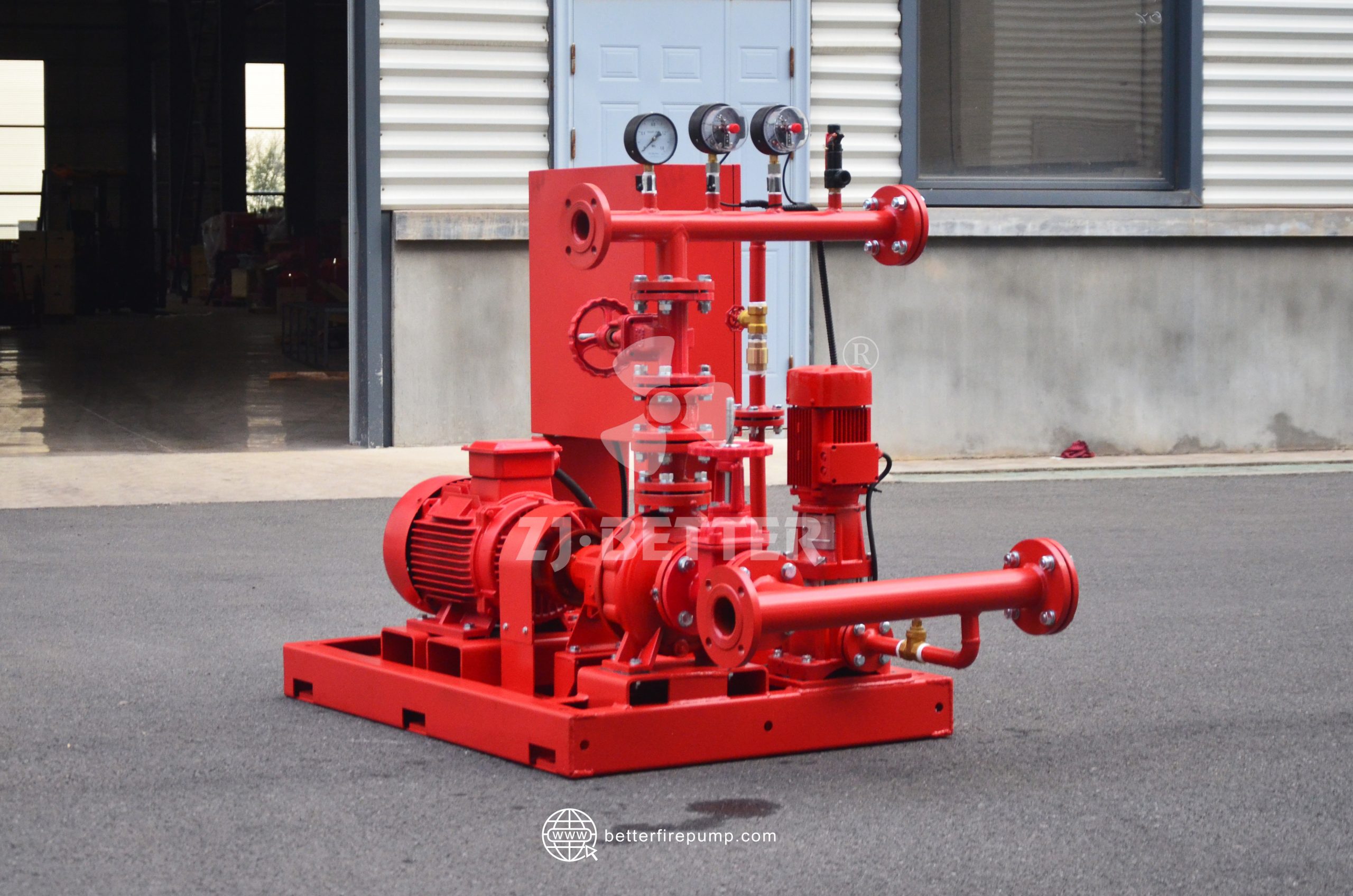

Fire pump sets designed to work outdoors

The national standard name of the diesel engine fire pump is “engineering diesel engine fire pump set”, and the national standard model is XBC-QYW/XBC-QYS where L is the lift value and Q is the flow value. XBC diesel engine fire pump set is the latest according to the national standard GB6245-2006 “fire pump performance requirements and test methods”. This series of products has a wide range of lift and flow, and can fully meet the fire water supply in various occasions such as warehouses, docks, airports, petrochemicals, power plants, liquefied gas stations, textiles and other industrial and mining enterprises.

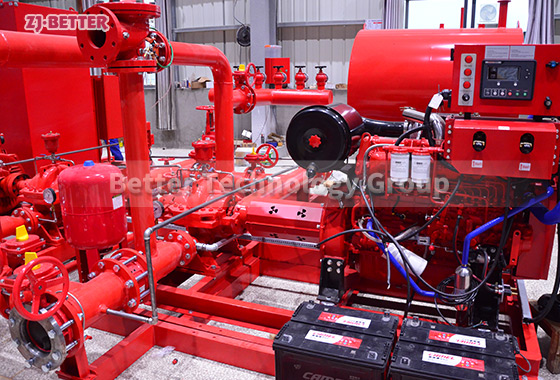

The engine cooling system of the diesel engine fire pump adopts double closed-loop heat exchangers. The system has the advantages of high cooling efficiency and little influence on the ambient temperature of the pump room. The cooling water flow direction is controlled by a ball valve from the pump outlet pipe to the heat exchanger, so that the cooling water temperature of the body is between 85 and 95 °C. If the water temperature is too high, the opening of the ball valve can be increased, the heat dissipation capacity of the heat exchanger can be increased, and the water temperature of the engine cooling water can be reduced. On the contrary, the opening of the ball valve can be closed to increase the water temperature of the engine cooling water.

Diesel engine fire pump sets, such as automatic control fire pump sets, add a solenoid valve in parallel with the ball valve in the heat pipe. Under normal circumstances, the solenoid valve is closed, and the cooling water can meet the engine cooling requirements through the gate valve. When the engine cooling water temperature exceeds 95°C, the solenoid valve will automatically open to increase the cooling water flow and reduce the engine cooling water temperature. After 20 seconds, when the water temperature of the diesel engine still exceeds 95°C, the automatic control system will issue an audible and visual alarm and call the staff to the scene to check the cause.