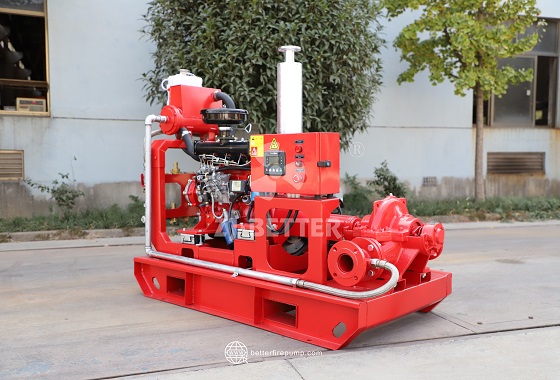

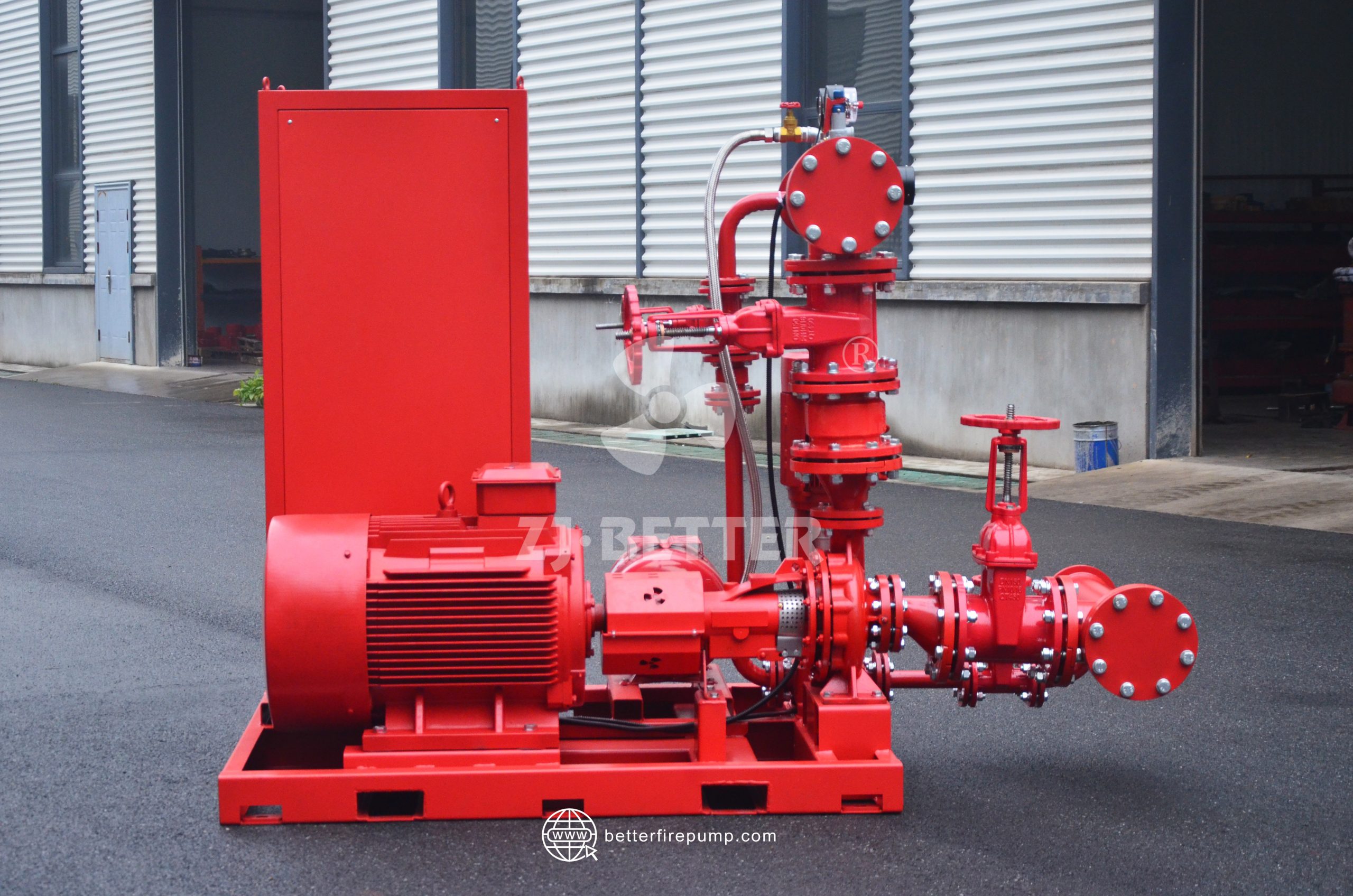

Introduction to the scope of application and structural characteristics of the horizontal electric fire pump set

Horizontal fire pump has significant advantages such as high efficiency, low operating noise, good cavitation resistance, reasonable structure and long service life. , long-distance water supply, heating, bathroom, boiler cold and warm water circulation pressurization, air conditioning refrigeration system water supply and equipment matching and other occasions.

The fire pump can be installed in multiple ways according to the on-site use conditions. And depending on the flow and head requirements, the required flow and head are increased in parallel and series. The bearing adopts low-noise closed bearing, which has been injected with grease before leaving the factory, which can ensure continuous operation for more than two years, and the components have high concentricity. The pump impeller has good performance. Dynamic balance, no vibration in operation, and improved use environment. The pump shaft seal is a mechanical seal, which solves the serious leakage of conventional centrifugal pump packing, increases the service life, and ensures that the operating site is clean and tidy.

Scope of application:

1. It is suitable for conveying clean water and substances with physical and chemical properties similar to clean water;

2. Medium temperature: -15℃~80℃;

3. Working pressure: system pressure ≤ 3.0MPa;

4. The ambient temperature should be lower than 40℃, and the relative humidity should be lower than 95%;

5. Since the main components of this type of pump are made of cast iron, the conveyed medium should be non-corrosive.

管道泵(不锈钢304316L).jpg)