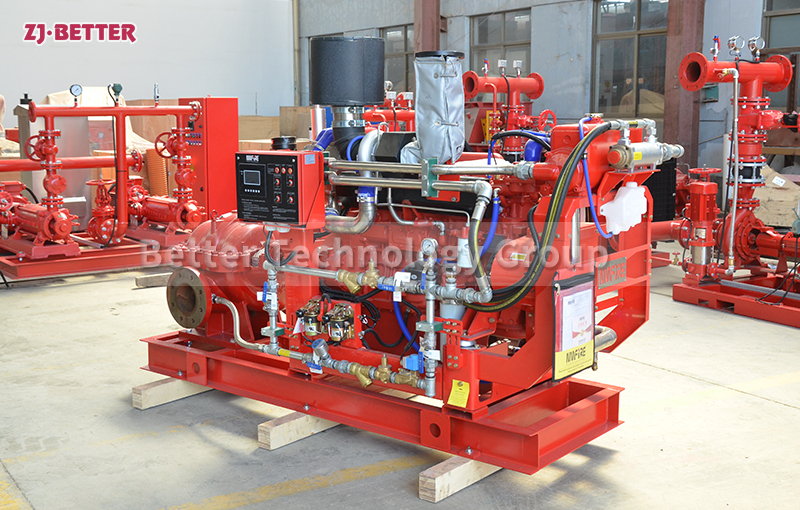

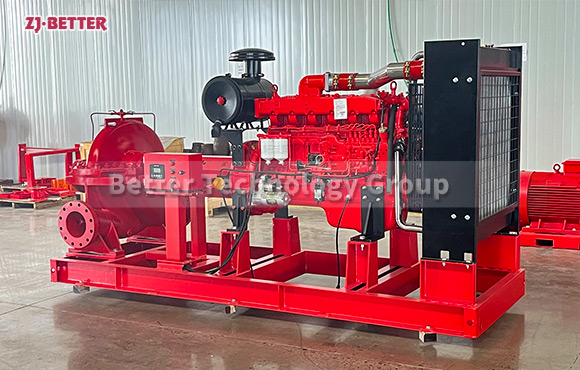

Stable High-Pressure Fire Pump System: Strong Protection for Critical Fire Situations

The stable high-pressure output fire pump system has the advantages of high head, large flow, and continuous and stable output. It adopts advanced hydraulic design and intelligent control to achieve automatic start and stop and constant pressure water supply. It is suitable for various fire protection scenarios such as high-rise buildings, industrial parks, and municipal projects. It ensures rapid water supply and efficient fire extinguishing in fire emergencies. It is an ideal core equipment for modern fire protection systems.

The stable, high-pressure output fire pump system is a high-performance firefighting device designed specifically to handle a variety of complex fire scenarios. Its efficiency, stability, durability, and reliability make it an indispensable core fire water supply system for numerous industrial, commercial, and residential buildings. In modern buildings and large-scale infrastructure, fire emergency response systems require sufficient water pressure and flow within a short period of time to ensure the efficient operation of firefighting equipment. The stable, high-pressure output fire pump system is the ideal solution to meet this demand. Through advanced hydraulic design, a powerful drive mechanism, a precise automatic control system, and the use of high-quality materials, this system achieves exceptional performance with high head, large flow, and continuous, stable output. This system demonstrates superior emergency water supply capabilities and long-term operational stability in high-rise buildings, chemical plants, power facilities, ports, and municipal engineering projects. Utilizing a high-efficiency centrifugal or multi-stage pump design, this fire pump system is capable of establishing stable water pressure output in a very short period of time. Its most significant feature is its robust pressure maintenance capability, ensuring stable output pressure regardless of the number of sprinklers or fire hydrants operating simultaneously, thus ensuring continuous and reliable firefighting operations. The high-pressure output capability not only ensures efficient long-distance water delivery but also enables the system to maintain sufficient flow even in high-rise buildings and large industrial plants. The pump body and impeller are typically cast from a high-strength, corrosion-resistant alloy and undergo high-precision dynamic balancing, ensuring low vibration, low noise, and low energy consumption over long-term operation. The drive system is a key component of the equipment’s performance and can be equipped with either an electric motor or a diesel engine, depending on site conditions. The electric motor offers fast response and smooth startup, making it suitable for locations with stable power supplies. For locations with potential power outages or in remote areas, a diesel engine option is available, ensuring automatic system startup and continuous water supply in any emergency. The diesel engine-driven system features a separate fuel tank, cooling system, lubrication system, and electronic starting device, ensuring reliable operation in harsh environments. The stable high-pressure output fire pump system utilizes a fully automatic intelligent control cabinet, utilizing microcomputer logic control for automatic pump start, stop, switching, and pressure monitoring. The control panel features various status indicators, alarms, and a real-time data display module for comprehensive operational monitoring. If the system detects a pressure drop or a fire alarm, the pumps automatically start, rapidly increasing the pipeline pressure and maintaining a constant output. When the pressure returns to normal or the fire alarm is lifted, the system automatically shuts down. This entire process requires no human intervention, significantly improving emergency response speed and operational convenience. The control system also supports remote monitoring and can connect to the fire department via a communication module for centralized management and remote diagnostics. To ensure reliability under extreme conditions, the pump system incorporates multiple safety protection mechanisms, including overpressure protection, underpressure alarm, overload protection, phase loss protection, oil pressure alarm, and temperature alarm. If any parameter exceeds the set range, the system immediately issues an alarm and automatically initiates protective measures, effectively preventing equipment damage and operational interruption. Structurally, the entire system is mounted on a thickened steel base with a shock-resistant design, ensuring smooth operation and facilitating transport and on-site installation. All connecting components undergo rigorous sealing tests to prevent leaks and air intrusion, enhancing overall system tightness and efficiency. Another significant advantage of this fire pump system is its ease of maintenance and long service life. The pump body features a compact design with ample access for maintenance, allowing for simple routine maintenance such as replacing seals and checking bearing lubrication, significantly reducing maintenance costs. The use of a high-strength anti-corrosion coating and high-quality stainless steel fasteners ensures long-term operation in humid, high-temperature, and corrosive environments without compromising performance, extending the equipment’s lifespan. The stable high-pressure output fire pump system typically offers a head range of 70 to 250 meters and a flow rate of 20 to 500 liters per second. Specific parameters can be customized based on project requirements. Designed to comply with international fire protection standards, it features a high-efficiency performance curve and a wide operating range, adapting to firefighting needs of varying scales and complexities. Whether used in municipal fire protection, industrial and mining fire protection, or commercial complex sprinkler systems, this system provides continuous and stable hydraulic support to ensure smooth firefighting operations. Compared to traditional fire pumps, the stable high-pressure output fire pump system offers superior energy efficiency. By optimizing the hydraulic channel design and pairing it with a high-efficiency motor, it reduces energy consumption by 10% to 20%, lowering operating costs. The system also features an optional variable frequency control module that automatically adjusts pump speed based on real-time pressure demand, achieving intelligent, energy-saving operation. In non-fire conditions, the pump set operates at low speed, operating at full speed only when pressure drops or a fire alarm occurs, ensuring emergency response while avoiding energy waste. The system also excels in environmental protection and noise control. Its optimized impeller structure and sound insulation keep operating noise levels below national standards, making it suitable for installation in noise-sensitive locations such as commercial buildings, hospitals, and schools. The diesel-powered version is equipped with an exhaust purification system and a soundproof enclosure to ensure emissions meet standards without impacting the surrounding environment. The stable, high-pressure output fire pump system offers high flexibility and adaptability in engineering applications. Customizable configurations include a main pump, pressure-stabilizing pump, sprinkler pump, control cabinet, pressure tank, and accessories, making installation and commissioning easier. The system can be integrated with various fire protection systems, including automatic sprinkler systems, fire hydrant systems, and foam fire extinguishing systems, to achieve a comprehensive fire protection solution. In general, the stable, high-pressure output fire pump system, with its high performance, high reliability, and intelligent control, has become the preferred equipment for modern firefighting systems. It not only provides sufficient water pressure and flow in the shortest possible time, ensuring effective initial fire control, but also maintains stable output over extended periods of operation, providing a solid guarantee for building and personnel safety. Whether deployed in high-rise buildings, large industrial parks, airports and terminals, or petrochemical facilities, this system has earned widespread recognition for its superior quality and performance, becoming an indispensable core power source in modern firefighting systems.