Constant Pressure Variable Frequency Fire Pump System: Perfect Balance Between Intelligent Water Supply and Energy Saving

The Constant Pressure Variable Frequency Fire Pump System is an advanced fire protection water supply solution integrating intelligent control with energy efficiency. It automatically regulates water pressure, rapidly responds to fire incidents, and maintains stable output, making it suitable for high-rise buildings, industrial plants, commercial complexes, and other diverse settings. Its variable frequency control technology ensures constant pressure water supply, reduces energy consumption, extends equipment lifespan, and provides reliable assurance for fire safety.

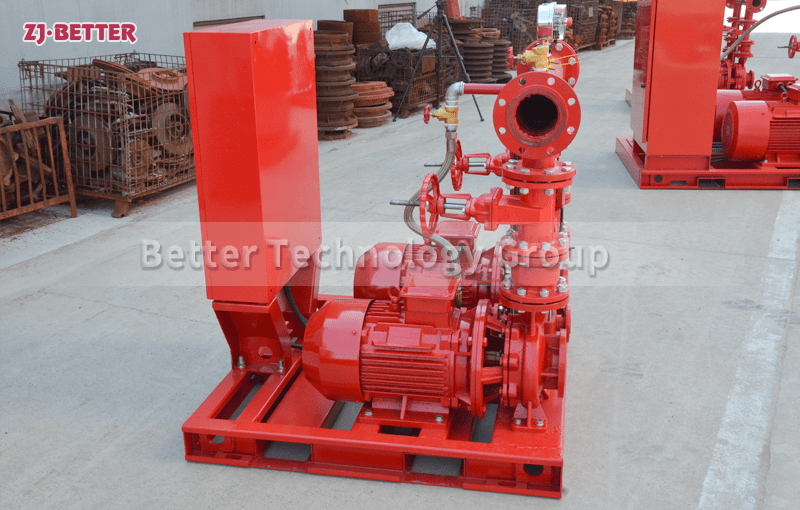

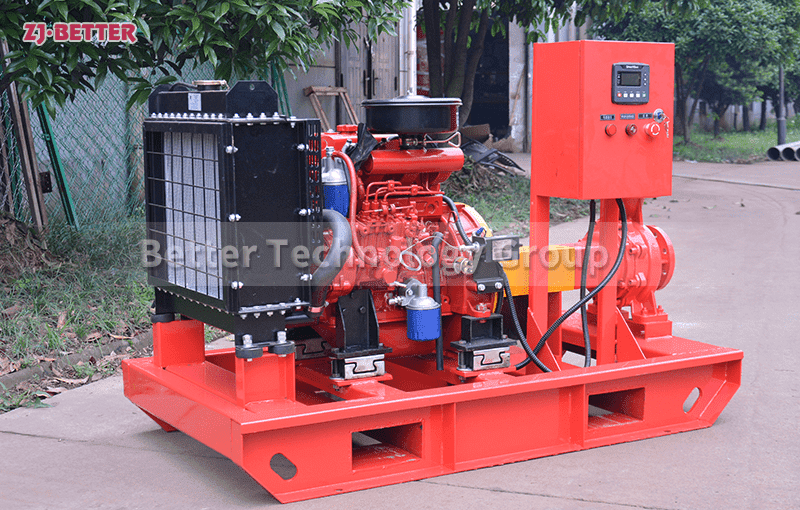

The Constant Pressure Variable Frequency Fire Pump System is a modern firefighting device integrating intelligent control, high energy efficiency, and stable water supply. Specifically designed for fire protection systems in various buildings, industrial facilities, commercial complexes, and high-rise residential buildings, its core advantage lies in automatically adjusting operating parameters under different fire conditions. This ensures constant water pressure, rapid response, and reliable operation, thereby providing continuous and robust power assurance for fire safety. The system comprises an electric fire pump, variable frequency control cabinet, pressure-stabilizing pump, pressure sensor, pressure tank, and piping system. Utilizing intelligent control technology, it achieves automatic start/stop functions, real-time monitoring, and constant-pressure water supply. During fire emergencies, it responds swiftly while maintaining optimal operational status to meet firefighting demands under all conditions. Compared to traditional fixed-speed pump systems, the Constant Pressure Variable Frequency Fire Pump Unit represents a revolutionary technological advancement. Its variable frequency control system automatically adjusts pump speed based on pipeline pressure fluctuations, ensuring output pressure remains within preset limits. This prevents pipeline vibrations or system failures caused by pressure fluctuations while effectively reducing energy consumption and extending equipment lifespan. During standby, the system automatically switches to a pressure-stabilizing pump, maintaining pipeline pressure with low power and minimal flow. This ensures instant water supply while minimizing energy waste. Upon detecting rapid pressure drops or fire system activation signals, the main pump immediately starts at full load, delivering ample firefighting water volume and stable pressure. This guarantees prompt and effective operation of fire hydrants or sprinkler systems, maximizing fire suppression efficiency. The constant-pressure variable-frequency fire pump system features a high-performance motor and premium pump design, delivering high head, large flow, low noise, and minimal vibration for stable, reliable long-term operation. The pump body is typically constructed from high-quality cast iron or stainless steel, offering strong corrosion resistance suitable for diverse water conditions. Impellers undergo dynamic balancing to ensure high-efficiency operation and minimize mechanical wear. Advanced mechanical seal structures prevent leakage, enhancing overall system sealing integrity and safety. Regarding the control system, the constant-pressure variable-frequency fire pump unit incorporates an advanced PLC intelligent control module. It supports manual, automatic, and remote multi-mode switching, featuring multiple protection functions including overvoltage, undervoltage, overload, phase loss, short circuit, and overheating. Additionally, it provides operational status display, fault alarms, historical data logging, and communication interfaces. This enables integrated management with building fire control centers, monitoring systems, or remote cloud platforms, thereby enhancing overall fire automation levels and management efficiency. During system operation, variable frequency speed control technology not only automatically adjusts output based on demand during non-fire conditions but also effectively prevents water hammer effects. This protects pipelines and valves from impact damage, reduces maintenance frequency, and extends equipment service life. The energy-saving performance of constant-pressure variable-frequency fire pump systems is particularly outstanding. Compared to traditional fixed-speed pumps, energy consumption can be reduced by 30% to 50%. Especially during periods of low pipeline demand, maintaining constant-pressure water supply through automatic variable-frequency speed control significantly reduces the losses from prolonged full-load motor operation, achieving true high-efficiency energy savings and green fire protection. The system design prioritizes operational safety and convenience. Its compact structure minimizes footprint while simplifying installation and maintenance. Customizable configurations—single, dual, or multi-pump parallel operation—accommodate diverse building structures and flow requirements for fire protection systems of varying scales. All electrical components utilize high-reliability industrial-grade parts, ensuring stable performance in harsh environments including high temperatures, humidity, and strong electromagnetic interference. User-friendly features include one-touch start, automatic reset, and a visual interface, enabling operators to monitor equipment status effortlessly and respond swiftly to emergencies. During prolonged operation, the system employs intelligent control algorithms to learn and optimize pipeline pressure curves, automatically adjusting control strategies to maintain peak operational efficiency. The Constant Pressure Variable Frequency Fire Pump System is suitable for diverse buildings including commercial complexes, industrial plants, hospitals, hotels, schools, and high-rise residences. It is also widely adopted in fire protection water supply systems across petrochemical, power generation, port, and warehousing industries. The system seamlessly integrates with multiple fire protection facilities such as sprinkler systems, fire hydrant systems, and foam extinguishing systems, enabling multi-system coordinated control to enhance emergency response speed. Due to its superior stability and intelligent control capabilities, this system is increasingly becoming the mainstream choice in fire safety applications. Its sustainable operation ensures constant output pressure even during power fluctuations or environmental changes, guaranteeing the fire protection system remains in optimal condition at all times. Additionally, the system offers optional remote monitoring modules, enabling data collection and remote diagnostics via network connections. This facilitates real-time monitoring of equipment status by maintenance personnel, allowing timely maintenance and fault resolution to prevent safety hazards caused by delays. In summary, the core advantages of constant-pressure variable-frequency fire pump systems are: First, pressure stability ensures continuous balanced water pressure for reliable firefighting equipment operation. Second, energy efficiency and environmental friendliness are achieved through variable-frequency speed control technology, effectively reducing energy consumption and operational costs. Third, high automation enables fully automatic operation and intelligent monitoring. Fourth, operational reliability is ensured by comprehensive protection measures and high-quality components, minimizing failure rates. fifth, simplified maintenance through modular design for quicker repairs; sixth, strong compatibility with diverse fire protection systems and building scenarios. Consequently, this system has become an indispensable component in modern fire protection systems, delivering safe, efficient, and stable firefighting water supply for various buildings and facilities. It not only represents advancements in fire equipment manufacturing technology but also embodies the seamless integration of modern intelligent control and energy-saving concepts, providing robust technical support and a reliable power core for global fire safety.