Continuous Duty Vertical Fire Pump for Stable Fire Water Pressure

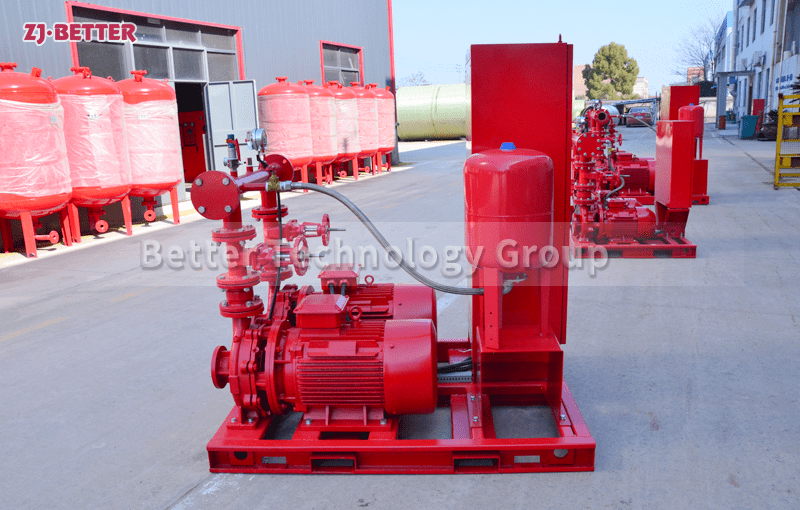

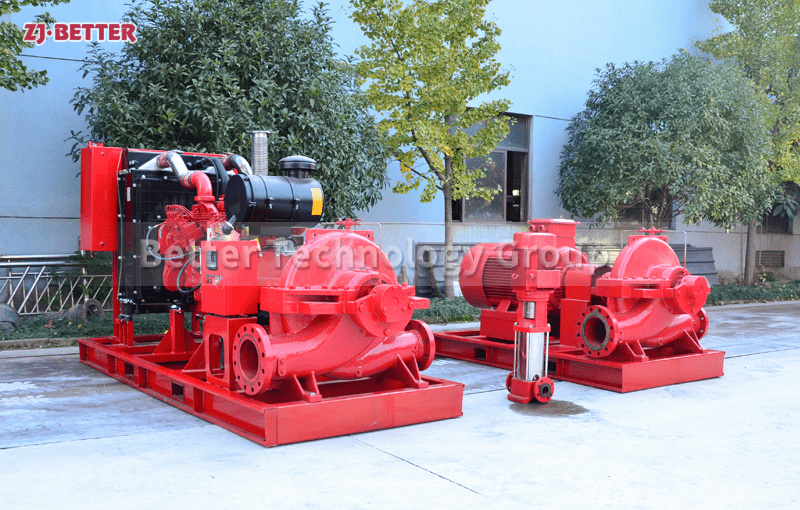

Vertical fire pumps that operate continuously for extended periods offer stable flow and pressure output, occupy a small footprint, and are reliable in operation. They are suitable for high-rise buildings, industrial plants, and various fire protection systems, ensuring continuous, stable, and safe fire water supply.

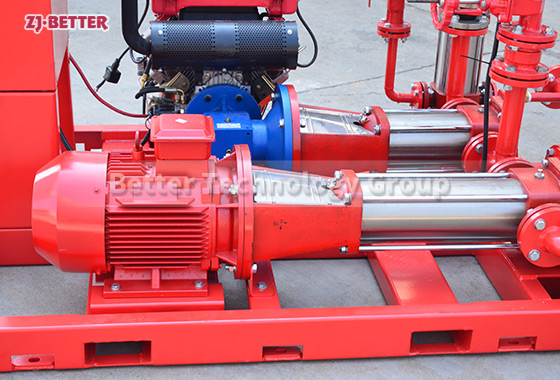

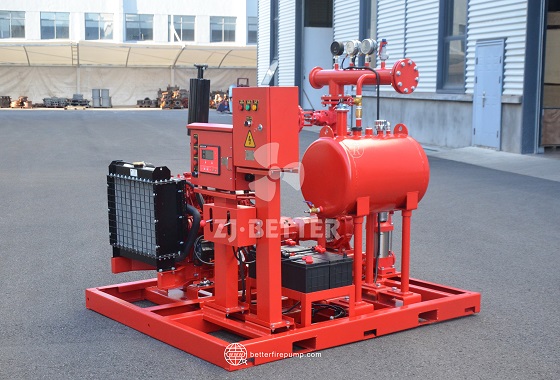

Vertical fire pumps designed for continuous long-term operation are core equipment specifically designed for the high reliability and continuous water supply requirements of fire protection systems. They are widely used in high-rise buildings, commercial complexes, industrial plants, warehousing and logistics centers, underground projects, and municipal fire protection systems. Their core advantage lies in maintaining stable flow and pressure output during fires and prolonged firefighting operations, ensuring a continuous and reliable water supply to the fire protection network without performance degradation due to extended operating time. These vertical fire pumps feature a vertical structure design, occupying a small area and having a compact overall layout. They are particularly suitable for engineering environments with limited space in the fire pump room or requiring the centralized arrangement of multiple units. The vertical structure also facilitates vertical pipe connections, reducing the number of bends and hydraulic losses, thus improving overall water supply efficiency at the system level. The pump’s hydraulic model has undergone meticulous design and repeated optimization, maintaining high efficiency under both rated and deviated operating conditions, ensuring a stable water output under different firefighting conditions and meeting the diverse needs of fire hydrant systems, automatic sprinkler systems, and other fire water scenarios. To meet the requirements of long-term continuous operation, this vertical fire pump has significant advantages in material selection and structural strength. Key flow components are typically made of high-strength, wear-resistant materials, possessing excellent erosion resistance and corrosion resistance. This allows it to adapt to impurities in fire-fighting water and long-term static water storage environments, effectively extending the equipment’s service life. The pump shaft is made of high-strength alloy steel and undergoes a rigorous heat treatment process, exhibiting excellent bending and fatigue resistance. Even under prolonged high-speed operation, it maintains good mechanical stability, reducing shaft vibration and wear. The bearing system uses high-quality industrial-grade bearings, combined with a scientific lubrication design, effectively controlling temperature rise and reducing friction loss under continuous operating conditions, ensuring stable and reliable operation of the entire unit. The sealing structure is a crucial guarantee for the stable performance of a continuously operating fire pump. This vertical fire pump typically employs high-performance mechanical seals or combined sealing solutions, featuring high temperature resistance, high pressure resistance, and wear resistance. It maintains good sealing performance during frequent start-ups and shutdowns and long-term operation, effectively preventing leakage and improving system operational safety. The drive motor is a high-efficiency industrial motor with excellent insulation and protection performance, enabling long-term stable operation in high-humidity and high-temperature pump room environments. Its high efficiency and low energy consumption help reduce operating costs while meeting fire protection performance requirements. The control system配套的控制制 (matching the motor) typically integrates multiple monitoring and protection functions, monitoring key parameters such as current, voltage, and operating status in real time. It promptly issues alarms or takes protective measures in case of abnormal operating conditions, effectively preventing equipment damage due to overload, phase loss, or other electrical faults, further ensuring the reliability of the fire protection system. This vertical fire pump is designed with the characteristics of fire protection equipment requiring long-term standby and reliable startup in critical situations in mind. Its robust overall structure, simple and reliable operating logic, and clear maintenance points facilitate daily inspection and maintenance, significantly reducing the difficulty and cost of later operation and maintenance. Its continuous water supply capacity is particularly outstanding. In actual fire protection applications, even with long-term uninterrupted water supply, it maintains stable head and flow output without significant performance degradation due to extended operating time, fully meeting the stringent requirements of fire protection codes for continuous water supply capacity and system stability. These vertical fire pumps also possess excellent system compatibility, allowing for flexible integration with fire water tanks, pressure stabilizing devices, control cabinets, and various fire pipeline systems to form a complete and efficient fire water supply solution. They are suitable for fire protection projects of different scales and types. With their high hydraulic performance, reliable mechanical structure, excellent continuous operation capability, and convenient installation and maintenance, vertical fire pumps capable of long-term continuous operation have become crucial equipment in modern fire protection systems for ensuring stable pressure and continuous water supply. They provide solid and reliable technical support for building and industrial fire safety, enhancing the overall safety level of fire protection systems while also bringing higher operational reliability and long-term service value to engineering projects.