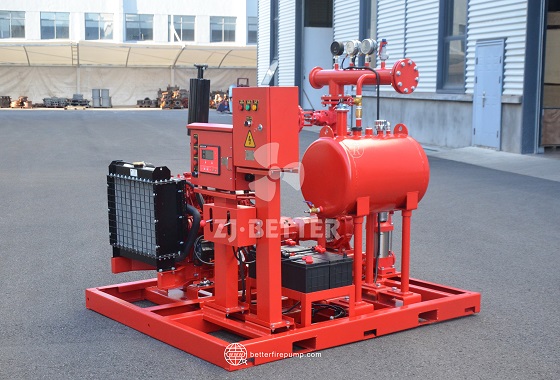

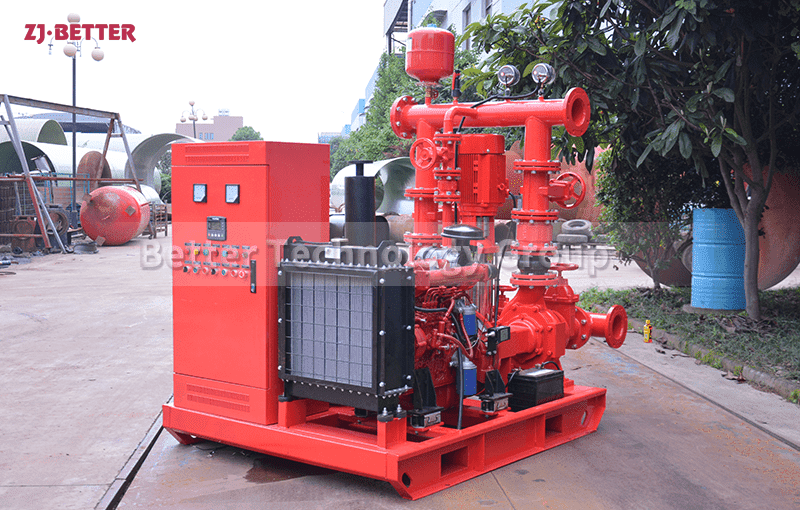

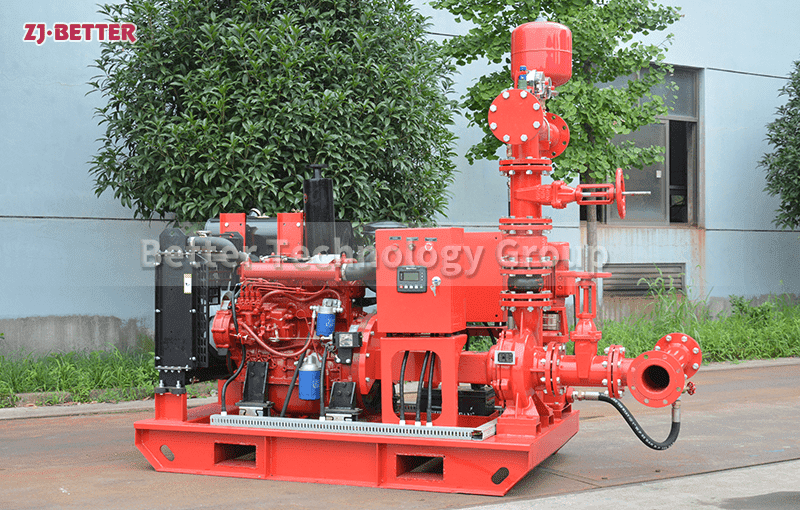

Diesel Fire Pump Package with Pressure Stabilization for Constant System Performance

The diesel fire pump system, equipped with a pressure stabilization device and independent diesel power, can quickly start and provide stable water supply in the event of a power outage. It boasts advantages such as high head, large flow rate, reliable operation, and convenient maintenance, making it suitable for industrial plants, municipal projects, high-rise buildings, and critical fire water supply applications.

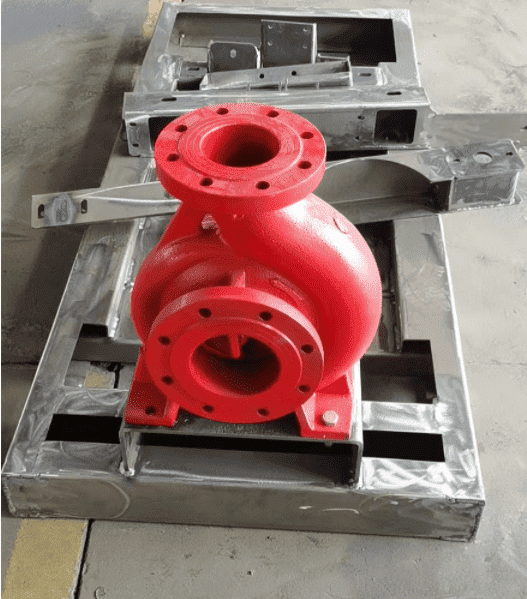

This complete diesel-powered fire pump system utilizes an independent diesel engine drive and integrates a pressure stabilization device, specifically designed for applications requiring extremely high stability and continuity of fire water supply. It demonstrates significant advantages in municipal fire protection networks, industrial plants, large warehousing and logistics parks, high-rise and super high-rise buildings, petrochemical facilities, power plants, ports and docks, and fire protection systems in remote areas. The entire system is centered around a high-performance fire pump, directly driven by a diesel engine. Even in the event of power outages, unstable power supply, or complete lack of electricity, it can start quickly and operate continuously and stably, ensuring sufficient water volume and stable pressure are provided to the fire protection network immediately in case of fire. The system’s pressure stabilization device automatically adjusts the network pressure during daily standby and low-flow water usage, preventing pressure fluctuations, water hammer effects, and frequent equipment starts and stops, effectively extending the service life of the entire fire protection system while improving overall operational safety and reliability. The diesel engine features a mature and stable industrial-grade structural design, characterized by low speed, high torque, reasonable fuel consumption, and strong durability. It is suitable for long-term standby and continuous high-load operation in emergency situations. Combined with an efficient cooling system and a reliable lubrication system, it maintains stable performance output in complex environments such as high temperature, low temperature, high humidity, or dusty conditions. The fire pump’s hydraulic model has been precisely calculated and optimized. The impeller, pump casing, and key flow-through components are manufactured from high-strength, wear-resistant, and corrosion-resistant materials. It maintains excellent hydraulic efficiency under high-head and high-flow conditions, reducing energy loss and ensuring stable water pressure and sufficient flow to meet the fire protection needs of multiple simultaneous water points and long-distance transportation. The entire system adopts a modular integrated design, rationally arranging the diesel engine, fire pump, pressure stabilization device, control system, and piping valves on a high-strength base. The compact structure and small footprint facilitate transportation, hoisting, and on-site installation, significantly shortening the construction period and reducing overall installation costs. The intelligent control system enables automatic monitoring and management, providing real-time monitoring of the unit’s operating status, pressure changes, and start signals. It automatically starts the main pump when abnormal pipeline pressure or fire signals are detected, and continuously adjusts the output during operation to maintain pipeline pressure within the set range. This prevents insufficient pressure from affecting firefighting effectiveness and also prevents system damage due to excessive pressure. The control system supports both manual and automatic control modes, with clear operating logic and an intuitive interface, making it easy for maintenance personnel to quickly understand and use. It also features comprehensive alarm and protection functions, providing timely alerts in case of abnormal conditions such as overspeed, low oil pressure, and high water temperature, ensuring equipment and personnel safety. The pressure stabilization device plays a crucial buffering and regulating role in the system. By rationally matching volume and pressure parameters, it prevents frequent starting of the main fire pump during minor leaks or small water usage, thereby reducing diesel engine wear and fuel consumption, and improving the overall economy and reliability of the system. This complete diesel fire pump set is designed with maintenance convenience in mind. Key components are rationally arranged, providing ample maintenance space. Daily inspection, maintenance, and component replacement are simple, reducing future maintenance difficulties and costs. This makes it particularly suitable for fire protection projects requiring extremely high equipment stability and long-term operational reliability. The system has a high degree of standardization in its external interfaces, allowing for flexible matching with fire protection networks of different pipe diameters, pressure levels, and flow rate requirements. It has good scalability and adaptability and can be customized according to project needs. The entire unit undergoes rigorous performance testing and operational trials before leaving the factory to ensure stable operation under rated and extreme operating conditions, providing users with reliable fire water supply. With its independent power, stable pressure operation, efficient water supply, compact structure, convenient maintenance, and strong environmental adaptability, this diesel fire pump system with a pressure stabilization device has become an indispensable component in modern fire protection engineering, providing continuous, stable, and safe fire water support for various critical locations.