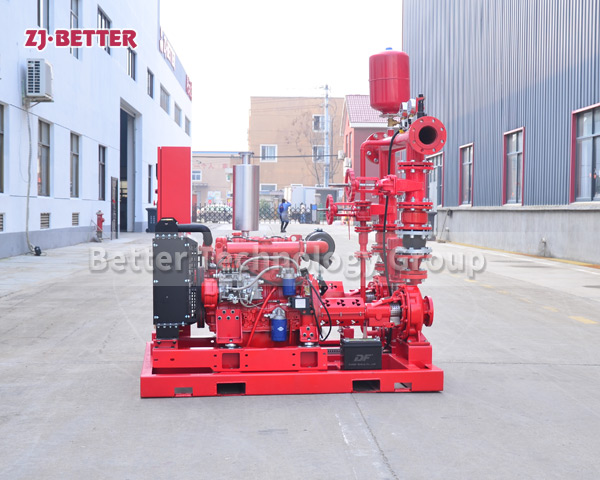

Vertical Electric Fire Pump Package for Industrial and Commercial Projects

The vertical electric fire pump complete set integrates a pressure stabilizing device and an intelligent control system, offering advantages such as high head, large flow rate, stable operation, and convenient maintenance. It is suitable for industrial plants, commercial buildings, and various fire water supply systems, meeting the high standards of modern fire protection engineering.

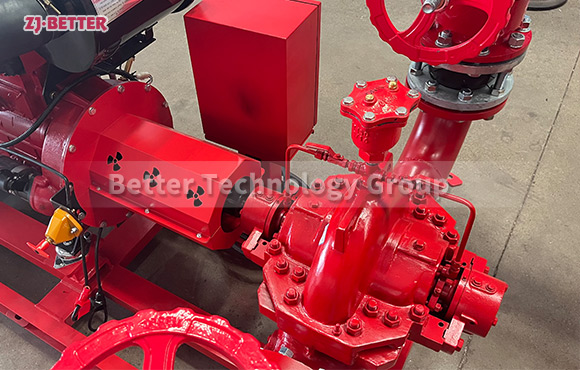

This vertical electric fire pump set is specifically designed for fire water supply systems in industrial and commercial projects. It features a compact overall structure, stable performance, and comprehensive configuration, meeting the high standards, systematization, and reliability requirements of modern buildings for fire safety. The entire system is centered around a high-efficiency vertical fire pump, driven by an electric motor, and highly integrated with a pressure stabilization device, pipe valve group, and intelligent control system. This achieves high head, large flow rate, and stable pressure output within limited pump room space, making it particularly suitable for applications requiring extremely high continuity and response speed in fire water supply, such as industrial plants, commercial complexes, warehousing and logistics centers, hospitals, data centers, and high-rise public buildings. The fire pump body’s hydraulic design fully considers the special characteristics of fire fighting conditions. By optimizing the impeller flow path and pump casing structure, the equipment achieves excellent hydraulic efficiency and a stable performance curve under rated operating conditions. Even under conditions of simultaneous water use at multiple points or long-distance transportation, it maintains reliable water pressure and sufficient flow rate, providing a continuous and powerful water source guarantee for the fire extinguishing system. Key flow-through components are manufactured from high-strength, wear-resistant, and corrosion-resistant materials, capable of withstanding high pressure and high-speed operating environments for extended periods, effectively reducing wear and performance degradation, and extending the service life of the entire unit. This is particularly suitable for the complex water quality and long-term standby operating requirements in industrial environments. The electric motor and pump body are well-matched, ensuring rapid start-up, stable operation, and good vibration and noise control, which helps improve the pump room operating environment and reduces the impact on surrounding buildings and equipment. The pressure stabilization device included in the complete system plays an important role in daily operation. By automatically adjusting the pipeline pressure, it prevents frequent starting and stopping of the main pump due to minor leaks or pressure fluctuations, thereby reducing mechanical wear on the motor and pump body and improving the reliability and economy of the entire fire fighting system. The intelligent control system is highly integrated, capable of real-time monitoring of equipment operating status, pipeline pressure, and power supply conditions. Upon receiving a fire signal or pressure anomaly command, it automatically starts the fire pump and continuously monitors various parameters during operation, ensuring that the equipment always operates in a safe and efficient state. The control logic is clear, supporting both automatic and manual operation modes, allowing on-site management and maintenance personnel to flexibly switch between modes according to actual working conditions. It also features comprehensive alarm and protection functions, providing timely warnings and taking protective measures in case of overload, undervoltage, overtemperature, and other abnormal situations, ensuring the safety of equipment and personnel. The entire system adopts a modular design concept, with the fire pump, motor, pressure stabilization system, control cabinet, and piping accessories rationally arranged on a high-strength base. The compact structure and balanced force distribution facilitate overall transportation, lifting, and on-site installation, effectively shortening the construction period and reducing overall project costs. The interfaces are highly standardized, allowing for flexible matching with various pipe diameters, pressure ratings, and system configurations according to the fire protection design requirements of different industrial and commercial projects, demonstrating excellent adaptability and expandability. The equipment design fully considers future maintenance needs; key components are rationally arranged, providing ample maintenance space. Routine inspections, maintenance, and parts replacement are simple, reducing operational difficulty and long-term costs. This vertical electric fire pump set undergoes rigorous performance testing and operational trials before leaving the factory, ensuring stable operation under rated and extreme working conditions, providing users with a reliable and durable fire water supply solution. With its efficient and stable water supply capacity, comprehensive system configuration, excellent environmental adaptability, and convenient installation and maintenance features, this equipment has become a widely used core component in industrial and commercial fire protection projects, providing a solid guarantee for the safe operation of various building fire protection systems.