Application and Performance Advantages of Stainless Steel Pressure Maintenance Units in Fire Protection Systems

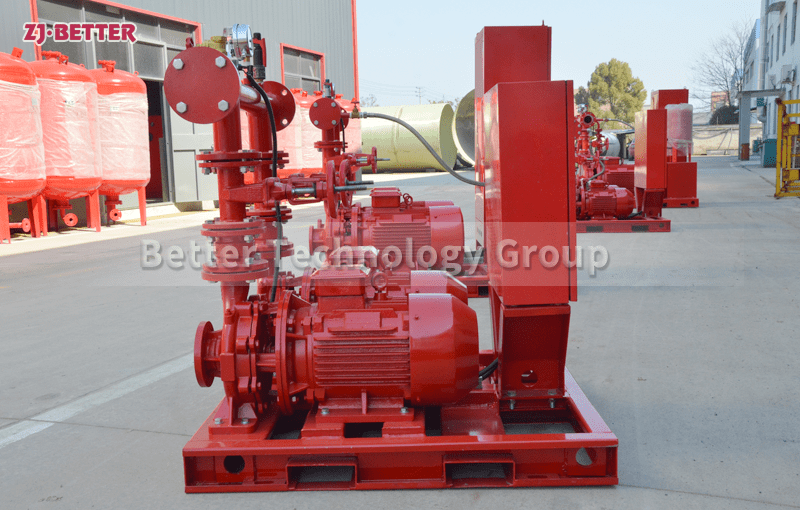

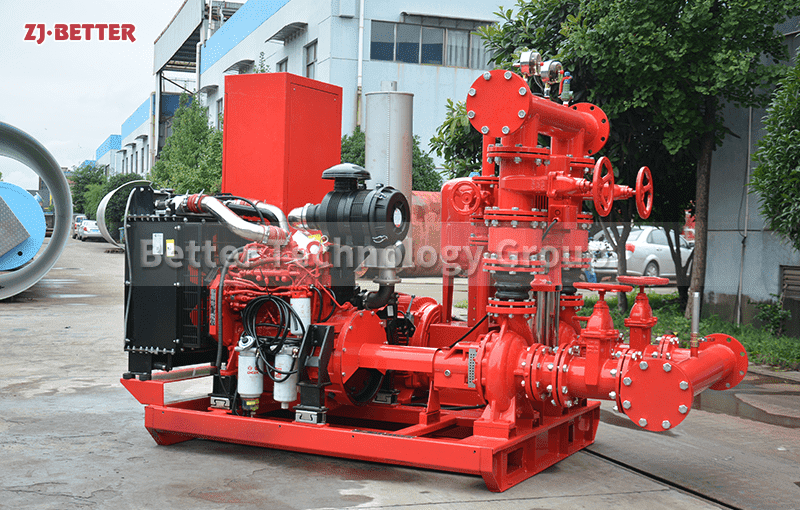

High-performance stainless steel pressure stabilization unit engineered for modern fire protection systems, delivering reliable pressure control, corrosion-resistant construction, intelligent monitoring, and long-term stable operation for commercial, industrial, and high-rise applications.

Stainless steel pressure stabilizing devices, as an indispensable component of modern fire protection systems, play a crucial role in maintaining stable pipeline pressure and ensuring that fire-fighting equipment is always ready for operation. Their overall structure includes a pressure stabilizing tank, stainless steel piping, multi-functional control valve assemblies, pressure monitoring devices, and a pressure stabilizing control system. Through precise pressure regulation, they ensure the entire fire water supply system maintains suitable pressure in non-fire conditions and can quickly activate the main pump and achieve uninterrupted water supply in the event of a fire. Compared to traditional carbon steel materials or simple pressure stabilization methods, stainless steel pressure stabilizing devices have significant advantages in corrosion resistance, durability, hygiene, safety, and long-term operational performance, making them particularly suitable for high-standard, high-intensity, and high-frequency use in building and industrial fields. In terms of structural design, the stainless steel pressure stabilizing device uses high-strength, corrosion-resistant stainless steel to manufacture core components, including the pressure stabilizing tank, piping, valves, and connectors. This effectively resists electrochemical corrosion, oxidative corrosion, and dirt deposition that may occur in long-term water supply systems, improving the overall stability and service life of the system. Because fire-fighting water supply networks operate under static pressure year-round, and the internal water environment is complex and corrosive, stainless steel ensures the tank’s interior remains clean and free of impurities, maintaining a high hygiene standard for the pressure stabilization system. This is particularly important for buildings highly sensitive to water quality, such as hospitals, food factories, and data centers. In terms of control performance, stainless steel pressure stabilization devices are typically equipped with high-precision pressure sensors and intelligent controllers. By monitoring network pressure data in real time, they automatically start and stop small-flow pressure-stabilizing pumps or control valves according to preset pressure ranges to maintain stable network pressure at the set value. Compared to traditional mechanical pressure control methods, electronic intelligent control offers faster response, smaller errors, and can record pressure fluctuations. Alarm systems alert to potential leaks, damage, or equipment malfunctions in the network, allowing for proactive maintenance and preventing major safety hazards caused by insufficient fire-fighting system pressure. Its automated management capabilities significantly reduce the need for manual operation and improve the overall operational efficiency of the fire-fighting system. In addition, the stainless steel pressure stabilizing device features a pressure-adaptive tank design with extremely high pressure adaptability. The tank volume is scientifically designed to effectively absorb instantaneous pressure fluctuations in the pipeline network, achieving a pressure buffering function, reducing mechanical losses caused by frequent start-stop of the main pump, and extending the service life of the main pump and related equipment. Simultaneously, multi-pump combined pressure stabilizing systems can be configured with single-pump, dual-pump, or multi-pump coordinated operation modes according to different building sizes and fire protection requirements. When water consumption or pressure fluctuations are large, different pump groups can be automatically switched, improving the flexibility and stability of system operation. For complex scenarios such as large commercial complexes, industrial plants, warehousing and logistics centers, and high-rise buildings, the stainless steel pressure stabilizing device has excellent adaptability, maintaining stable pressure during long-term operation and ensuring a sufficiently low pressure differential within the system when the fire main pump starts, resulting in a more stable and effective flow output. In terms of safety performance, the stainless steel pressure stabilizing device also has significant advantages. The pressure tank typically adopts a thick-walled, pressure-resistant structure, and through rigorous welding processes and full-process pressure testing, ensures that it will not deform or burst even under high-pressure environments. Equipped with safety valves and pressure relief valves, the system automatically releases pressure when it rises abnormally, effectively preventing equipment damage or dangerous accidents caused by pressure overload. The check valves, bypass pipelines, and drainage devices within the system effectively prevent backflow, water hammer, and reduce impurity accumulation, further enhancing the safety and stability of the entire fire protection system. In terms of installation and maintenance, the stainless steel pressure stabilizing device features a modular design, a compact structure, and a small footprint, allowing for flexible placement according to the size of the equipment room, making it suitable for both new construction and renovation projects. The optimized placement of each component facilitates daily maintenance, pressure calibration, and parts replacement, reducing operating costs. Because stainless steel has a much longer lifespan than ordinary materials, it reduces corrosion maintenance work during long-term operation, ensuring the fire protection system remains efficient, stable, and reliable for over ten years. Especially in areas with high humidity, strong corrosion, or poor water quality, the stainless steel pressure stabilizing device significantly improves system durability and reduces problems such as leakage and pressure instability caused by corrosion. In terms of application scope, stainless steel pressure stabilizing devices can cover almost all medium and large-scale fire protection systems, including but not limited to commercial complexes, office buildings, warehousing and logistics centers, hospitals, schools, industrial parks, chemical plants, power plants, high-rise residential buildings, underground parking lots, hotels, and public buildings. Their powerful pressure regulation capabilities and excellent corrosion resistance enable them to maintain long-term stable operation in various environments. For scenarios with extremely high requirements for fire water supply stability, such as data centers or major engineering projects, stainless steel pressure stabilizing devices are indispensable key equipment. As the requirements of modern fire protection systems continue to increase, stainless steel pressure stabilizing devices demonstrate irreplaceable advantages in performance reliability, intelligence, environmental friendliness, and long-term cost control. They not only ensure that the fire protection system maintains appropriate pressure in non-fire conditions but also provide rapid and effective pressure support in the event of a fire, making the entire fire water supply chain more stable and efficient. In future fire protection engineering construction, high-quality stainless steel pressure stabilizing devices will continue to play a crucial role in driving system upgrades; their advanced material technology, intelligent control capabilities, and excellent stability will provide a higher level of protection for building safety.