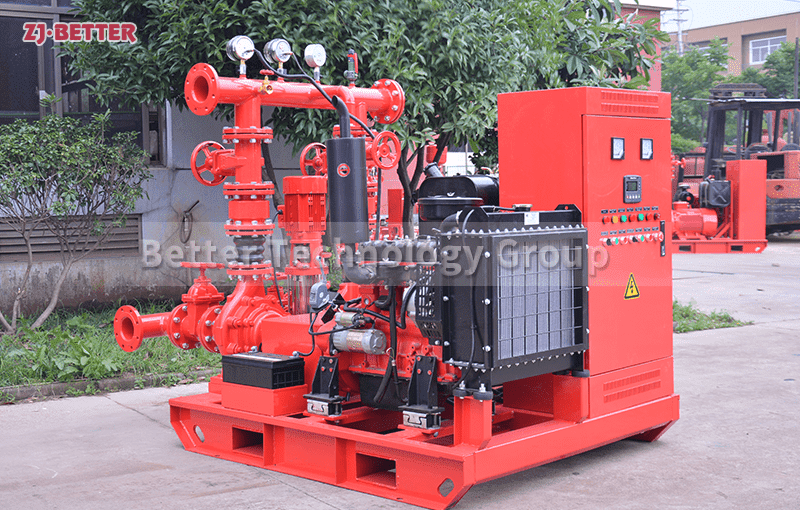

Independent Power Diesel Fire Pump System for Advanced Fire Safety Operations

Independently powered diesel fire pump systems provide reliable fire-fighting water supply for high-rise buildings, industrial parks, and remote areas. These systems offer advantages such as automatic start-up, powerful performance, high energy efficiency, intelligent control, and durability, ensuring continuous water supply during power outages or emergencies. They are an essential equipment choice for modern fire safety systems.

n modern urban construction and industrial fire protection systems, independently powered diesel fire pump systems play a crucial role. With the rapid development of high-rise buildings, chemical plants, warehousing and logistics centers, and remote facilities, ensuring a stable and reliable fire water supply under any circumstances has become a core requirement of fire safety design. Diesel fire pump systems, with their powerful output, independent energy supply, automated control, and superior durability, have become an ideal solution for fire water supply in environments without electricity or in emergency situations. They can not only operate continuously in extreme conditions such as fires, power outages, and earthquakes, but also provide efficient, safe, and sustainable fire protection for industrial, civil, and municipal sectors.

The most significant characteristic of diesel fire pump systems is their “independent power supply.” Unlike electric fire pumps, they rely on a diesel engine as their power source and are not limited by external power supply. When the city power grid is interrupted, substations fail, or power outages occur due to disasters, diesel fire pumps can start and operate immediately, ensuring a continuous water supply to the fire protection system. The system is typically equipped with an independent fuel tank, battery starting device, and automatic control system, ensuring automatic start-up upon receiving a fire signal or a drop in pipeline pressure, achieving true “unattended automatic operation.” This independence makes it an indispensable fire-fighting equipment in hospitals, data centers, airports, chemical plants, high-rise buildings, and underground projects.

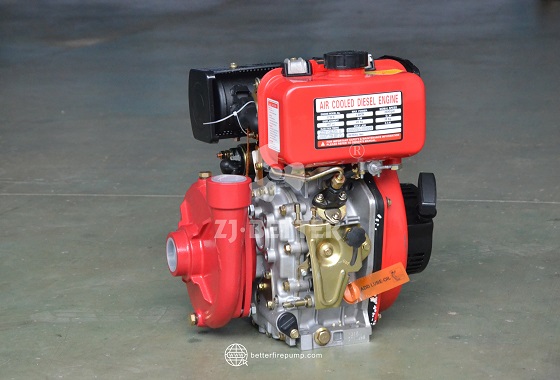

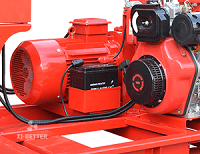

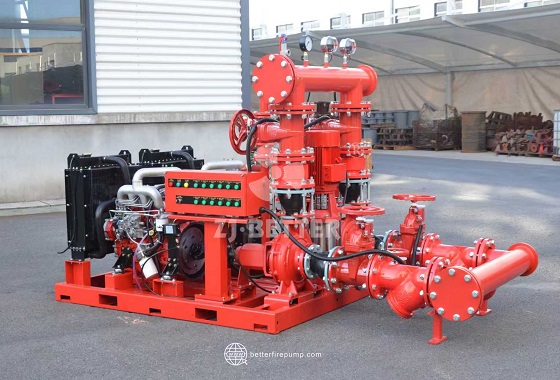

Structurally, a diesel fire pump system typically consists of a diesel engine, centrifugal pump, control cabinet, fuel system, cooling system, exhaust system, and foundation. The diesel engine directly drives the centrifugal pump through a coupling, converting mechanical energy into the kinetic and potential energy of water, thus achieving high-flow, high-lift fire-fighting water supply. The entire system is compact and rationally laid out. The pump body is mostly made of high-quality cast iron or stainless steel, possessing extremely strong pressure and corrosion resistance. The pump’s hydraulic components are optimized, with high impeller balance precision and smooth flow channels, effectively reducing water flow loss and improving efficiency. The diesel engine uses high-pressure common rail or direct injection technology, resulting in more complete combustion, stronger power, and lower fuel consumption. Through this efficient power transmission and energy conversion, the diesel fire pump can establish high-pressure water supply in a short time, meeting the needs of high-rise buildings, long-distance water supply, or high-flow sprinkler systems.

In terms of performance, diesel fire pump systems offer advantages such as rapid start-up, large flow rate, high head, stable operation, and low energy consumption. Upon receiving a start signal, the system can start and reach rated speed within 15 seconds, quickly providing stable water pressure to the fire protection network. Due to the high torque characteristics of the diesel engine, it maintains stable output even under load fluctuations or prolonged operation. The centrifugal pump section employs a high-efficiency hydraulic design, achieving an efficiency of over 75%. Combined with precisely machined impellers and pump bodies, it can achieve continuous and stable operation without excessive vibration or noise. Some systems are also equipped with variable speed control, automatically adjusting the pump speed according to pipeline pressure, thereby achieving energy-saving operation and extending equipment lifespan.

Regarding safety and reliability, diesel fire pump systems undergo multiple protection designs to ensure safe operation under various environmental conditions. The engine is equipped with multiple safety monitoring devices, including oil pressure alarm, temperature alarm, overspeed protection, and low fuel warning. The control system automatically shuts down and alarms upon detecting abnormalities to prevent mechanical damage. The fuel system adopts a leak-proof structure and is equipped with a fuel filter to ensure fuel cleanliness and stable combustion. The cooling system employs air-cooled or water-cooled circulation to effectively control engine operating temperature and prevent overheating. The exhaust system uses a muffler and fireproof cover to reduce noise and prevent safety hazards caused by high-temperature exhaust. Furthermore, the entire unit base is equipped with shock-absorbing rubber pads and fixing bolts, ensuring stable operation and facilitating transportation and installation.

In terms of automation control, the diesel fire pump system widely utilizes intelligent control technology to achieve fully automatic and remote management. A PLC programmable controller is installed in the control cabinet, enabling linkage with the fire control center. When pipeline pressure drops or a fire detection signal is received, the system automatically starts and operates; when the fire is extinguished and system pressure recovers, the pump unit automatically stops. Users can also monitor real-time operating parameters such as oil pressure, water pressure, speed, temperature, battery voltage, and running time through a human-machine interface, achieving intelligent monitoring and maintenance. For large industrial projects or urban complexes, the system can also be connected to a fire monitoring platform via a communication interface to achieve centralized control and remote fault diagnosis, greatly improving management efficiency and emergency response speed.

The application range of the diesel fire pump system is extremely wide, covering almost all areas requiring fire-fighting water supply. For high-rise buildings, it provides ample and stable water pressure, ensuring sufficient water supply for the top-floor sprinkler system and fire hydrants. For industrial parks, chemical plants, and warehousing facilities, it maintains independent water supply capabilities during power outages or in harsh high-temperature environments, preventing fire protection system failures due to power interruptions. For public infrastructure such as airports, train stations, subways, and tunnels, it is a crucial component of emergency backup water sources, ensuring rapid deployment in emergencies. In remote mountainous areas, oil drilling platforms, or agricultural irrigation areas, diesel fire pumps offer robust fire protection and drainage capabilities due to their mobility, flexibility, and independent power supply.

The system’s energy-saving and environmental performance is also continuously improving. Modern diesel engines employ advanced fuel injection control and emission treatment technologies, resulting in higher combustion efficiency, lower fuel consumption, and cleaner emissions. Some models are compatible with biodiesel fuel, further reducing carbon emissions and meeting green energy-saving standards. The centrifugal pump’s efficient hydraulic design reduces energy loss, while the variable frequency speed control system optimizes the operating curve, achieving on-demand water supply and significantly improving the overall energy efficiency ratio. In long-term operation, low maintenance costs and stable fuel consumption make diesel fire pump systems an economical, reliable, and sustainable choice for fire protection equipment.

From a maintenance perspective, diesel fire pump systems are relatively simple to maintain and manage. The system adopts a modular design, with components such as the engine, pump body, control cabinet, and fuel tank installed independently, facilitating inspection and replacement. Routine maintenance mainly includes fuel filter replacement, oil checks, battery charging, and impeller cleaning. Due to the high versatility and durability of diesel engine parts, only regular maintenance is needed to maintain long-term efficient operation. For projects with high operating frequencies, dual fuel tanks and automatic switching devices can be equipped to perform refueling and maintenance without interrupting operation, thus ensuring the continuous availability of the system.

From an economic perspective, although the initial investment of a diesel fire pump system is slightly higher than that of an electric pump set, its independent power supply, high reliability, and long service life make the overall operating cost more advantageous. In long-term operation, there is no need for additional backup power supplies or large generator sets, and it is not affected by power grid fluctuations, reducing infrastructure investment. At the same time, it can respond immediately in emergencies, greatly reducing the risk of fire losses; its economic and safety value cannot be measured by simple equipment costs.

With the advancement of smart cities and Industry 4.0, diesel fire pump systems are constantly being upgraded. The new generation of intelligent fire pumps can interface with building management systems (BMS) or fire protection IoT platforms to achieve functions such as data collection, operational analysis, remote alarms, and energy consumption statistics, facilitating the digital transformation of fire management. Future diesel fire pump systems will be more intelligent, efficient, and environmentally friendly, forming a hybrid water supply system with electric fire pumps and pressure-stabilizing pumps, creating a multi-energy complementary fire safety network.

In summary, independently powered diesel fire pump systems, with their powerful performance, reliable performance, intelligent control, and independent operation capabilities, have become an irreplaceable and crucial piece of equipment in modern fire protection systems. They not only solve the problem of fire water supply in environments without electricity but also demonstrate outstanding practical value in high-rise buildings, industrial parks, municipal infrastructure, and remote areas. With the improvement of fire safety standards and continuous technological advancements, diesel fire pump systems will undoubtedly continue to be widely used globally, providing a solid guarantee for the safe operation of cities and industries.