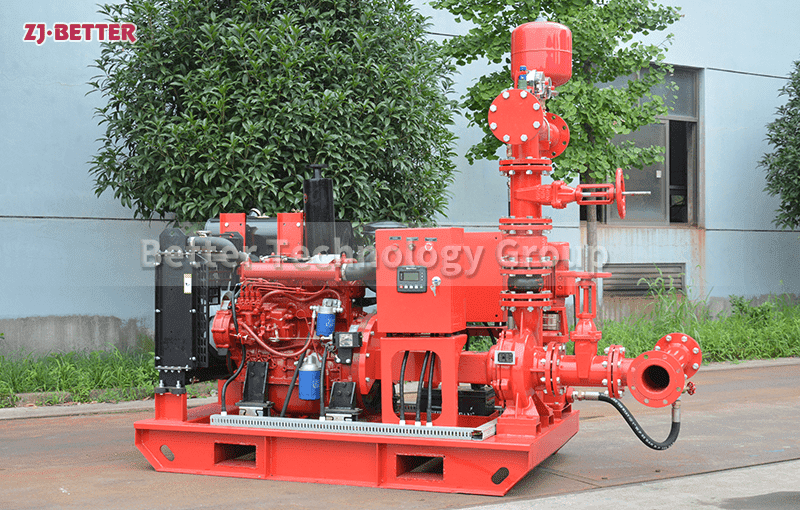

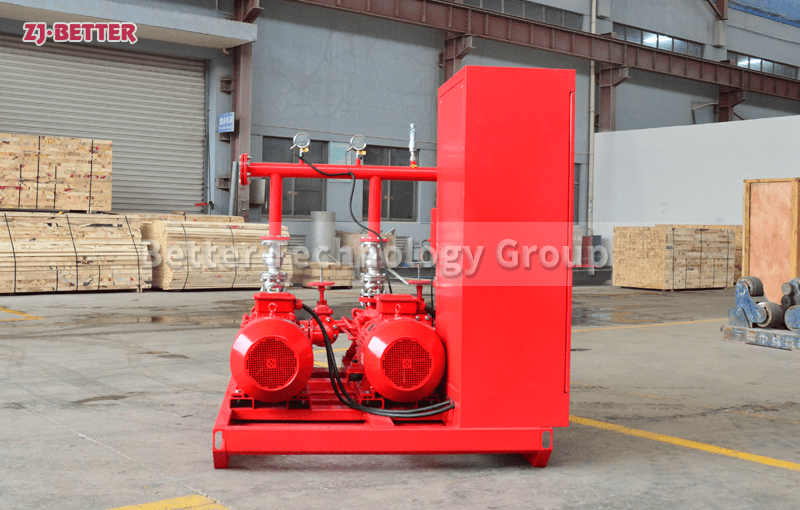

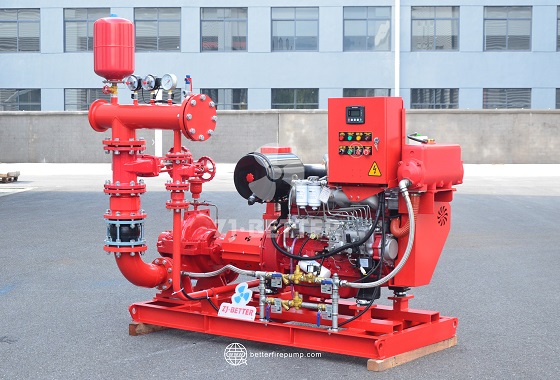

DJ (diesel + jockey) Fire Pump

Diesel engine fire pumps have been widely used in fire diversion as fixed fire extinguishing equipment, especially in the case of sudden fire water supply such as lack of power supply or abnormal power supply, fire pumps equipped with units are horizontal single-stage, multi-stage special fire pumps, mainly composed of diesel engines. , fire pump, connecting device, fuel tank, radiator, battery pack, intelligent automatic control screen, etc. Diesel engine fire pump products have the characteristics of leading technology, high degree of automation, excellent performance protection function, reasonable structure, simple installation and high cost performance. At the same time, in order to meet the different needs of users and reasonable investment, the products are divided into multiple application series such as fire pumps, industrial emergency pumps, agricultural pumps, marine pumps, trailer-type mobile water pump stations, etc., which can be used together with electric fire pumps.

1. Diesel engine pump, can use single stage pump, horizontal split case pump, end suction pump, multistage pump, material can be cast iron, stainless steel, and bronze impeller , with fuel tank, water tank£¬fan, control box

2. Jockey pump, horizontal or vertical, capacity will be small, but head should be higher than electric and diesel engine pump

Jockey material casing :cast iron ,shaft and impeller SS304

3. Control panel: Auto Control of diesel engine pump and Jockey Pump with overload, over current protection

4. Accessories: check valve, gate valve, pressure vessel, generally 0.6mpa, 1.0mpa, 1.6mpa, Pressure Gauge, Pressure Sensor, Common Pipe for Suction and Discharge, Flexible Joints and Flanges, Common Base plant